A data relay sub-section and a method for testing a logging-while-drilling tool

A logging-while-drilling and data relay technology, applied in surveying, earth-moving drilling, wellbore/well components, etc., can solve the problems of long preparation and test cycle, high site requirements, high cost, etc., to achieve convenient and efficient testing. Economical, improved reliability, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

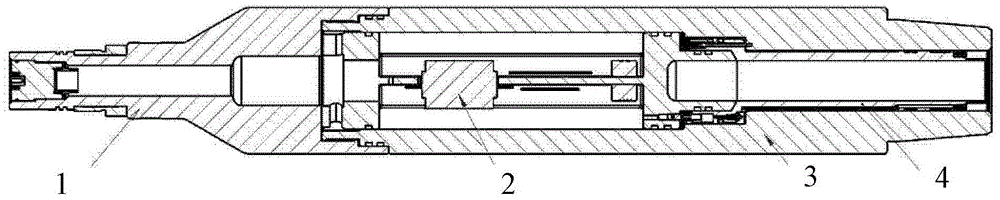

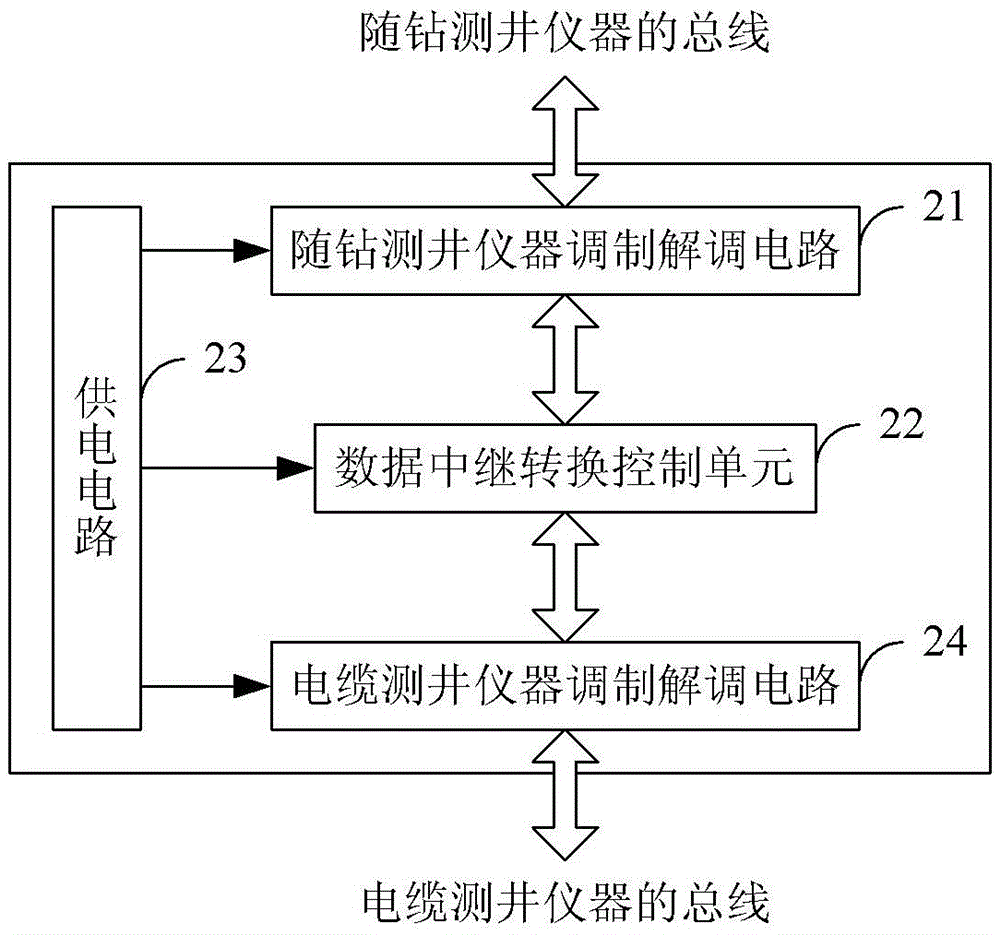

[0041] Embodiment 1. A data relay short section, including:

[0042] Wireline logging tool joint, built-in electrical connector of the wireline logging tool, used for mechanical and electrical connection with the wireline logging tool;

[0043] LWD tool connector, built-in LWD conductive ring, used for mechanical and electrical connection with LWD tool;

[0044] The relay control module is connected to the bus of the wireline logging tool and the bus of the logging while drilling tool; it is used to output the wireline logging system test command output by the wireline logging tool according to the logging while drilling sending the data format of the tool to the logging-while-drilling tool; and sending the data returned by the logging-while-drilling tool to the wireline logging tool according to the data format of the wireline logging tool.

[0045] The data relay nipple in this embodiment is connected between the wireline logging tool and the logging while drilling tool. t...

Embodiment 2

[0063] Embodiment 2, a method for testing a logging-while-drilling instrument, comprising:

[0064] The logging-while-drilling tool is connected to the wireline logging tool through the data relay sub-joint in Embodiment 1;

[0065] Convert the wireline logging system test command output by the wireline logging tool into the data format of the logging while drilling tool through the data relay sub, and send it to the logging while drilling tool;

[0066] The data returned by the logging-while-drilling tool is converted into the data format of the wireline logging tool through the data relay sub, and sent to the wireline logging tool.

[0067] In an implementation manner of this embodiment, the test commands of the wireline logging system may specifically include general control commands and commands for collecting and uploading data;

[0068] The step of sending the wireline logging system test command output by the wireline logging tool to the logging while drilling tool acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com