Processing method adopting lens group

A processing method and lens group technology, which can be applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., can solve the problems of increased production cost, tedious adjustment and correction process, low flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

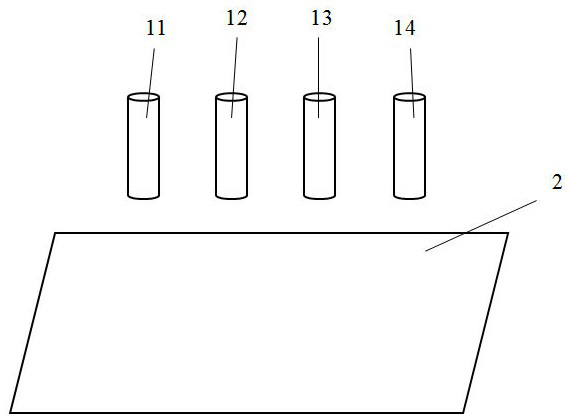

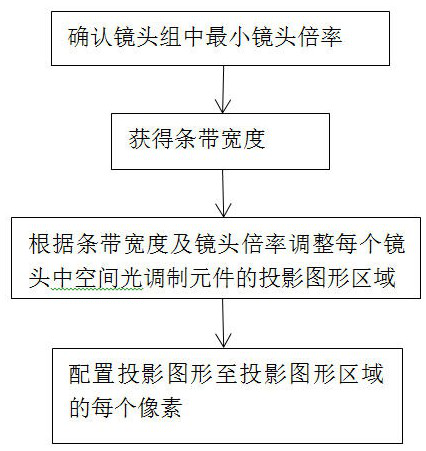

[0027] figure 1 A lens group is shown, and the lens group contains multiple lenses. The number of lenses in the lens group is not limited. It can be set as required. When the lens is projected, it is expected that the magnification of each lens is consistent, so that the The same strip width is convenient for matching with the moving device of the carrier 2, and it is beneficial for the strips between adjacent lenses to be well spliced. The following is a detailed description of the processing method when the lens magnifications in the lens group are inconsistent.

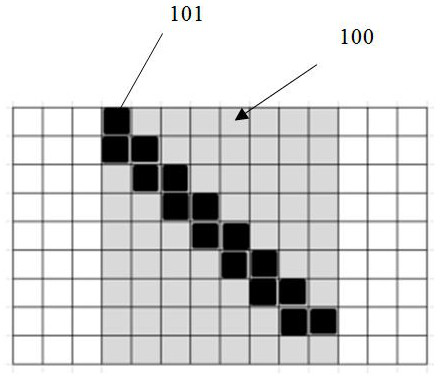

[0028] Now, the lens group includes four lenses as an example for description, namely the first lens 11, the second lens 12, the third lens 13 and the fourth lens 14. Each lens in the lens group includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com