Beam homogenization method and beam homogenization device

A homogenization and beam technology, applied in the field of optics, can solve problems such as uneven beam intensity distribution, many optical lenses, and light energy loss of frosted glass, so as to improve the homogenization effect and accuracy, expand the coverage area, and avoid complicated debugging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

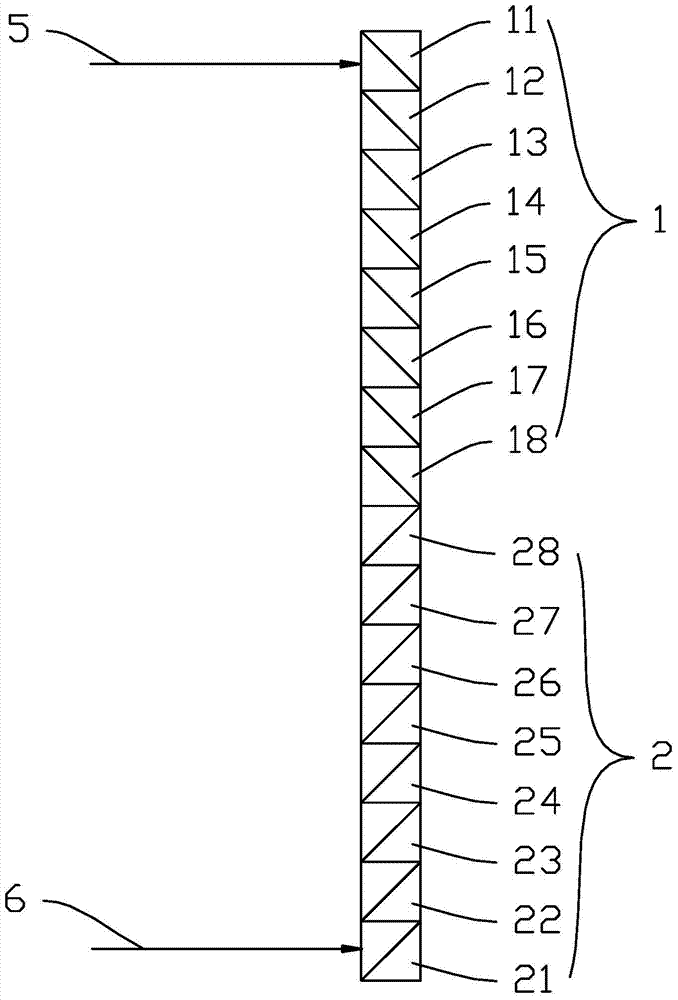

[0033] Such as Figure 1-3 As shown, the beam homogenizing device includes two substrates, which are a first substrate 1 and a second substrate 2 respectively. Wherein, the first substrate 1 and the second substrate 2 are arranged symmetrically on the same vertical plane.

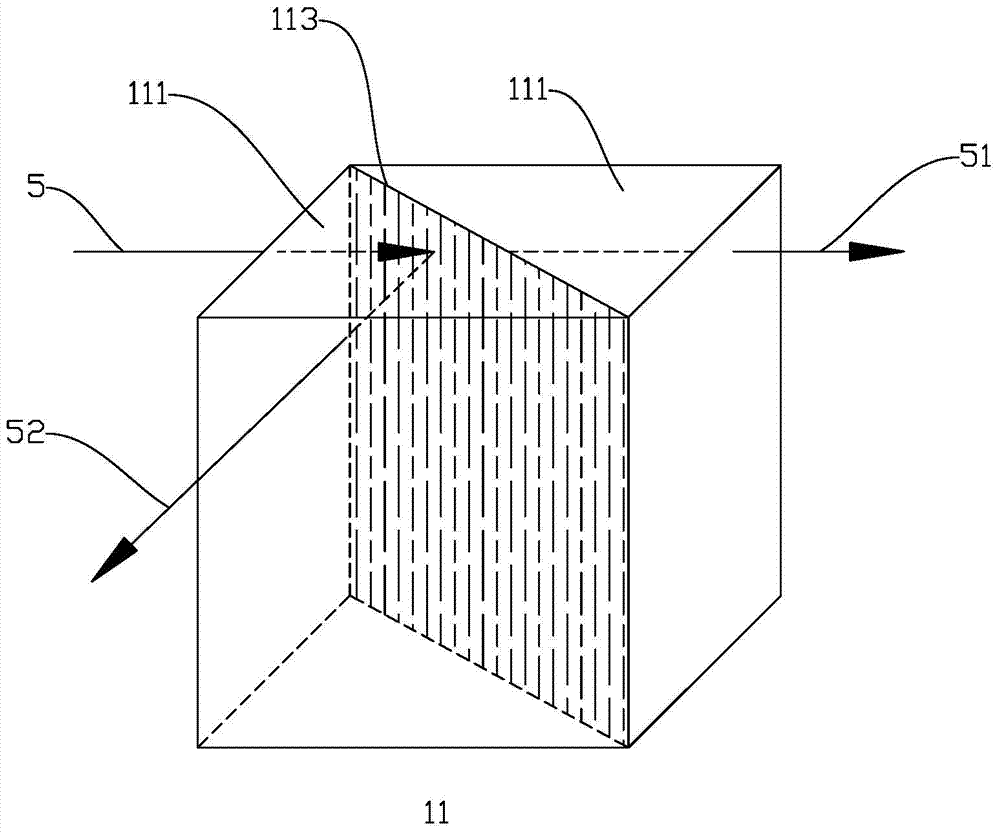

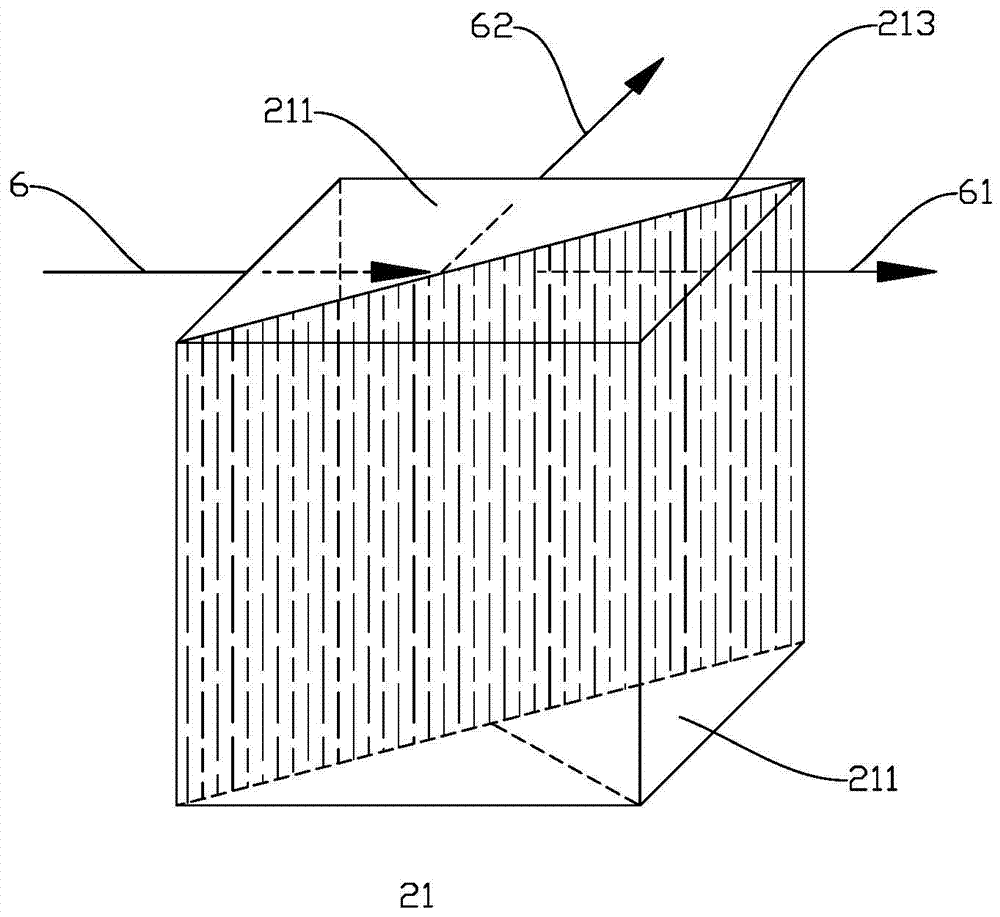

[0034] The first substrate 1 and the second substrate 2 have the same structure. Taking the first substrate 1 as an example, the first substrate 1 includes 8 beam splitters of equal size, from top to bottom are beam splitter 11, beam splitter 12, beam splitter 13, beam splitter 14, beam splitter 15, beam splitter mirror 16, beam splitter 17 and beam splitter 18. Taking the beam splitter 11 as an example, the beam splitter 11 is composed of two isosceles right-angle prisms 111 , and the isosceles right-angle prisms 111 are superimposed on each other so that their oblique surfaces touch each other to form a beam splitting surface 113 . A spectroscopic film (not shown in the figure) is disposed on the spect...

Embodiment 2

[0044] Such as Figure 5 As shown, the beam homogenizing device includes four substrates, namely a first substrate 1 , a second substrate 2 , a third substrate 3 and a fourth substrate 4 . Wherein, the first substrate 1 and the second substrate 2 are arranged symmetrically on the same plane. The third substrate 3 and the fourth substrate 4 are arranged symmetrically on the same plane. The structures of the first substrate 1, the second substrate 2, the third substrate 3 and the fourth substrate 4 are the same.

[0045] The third substrate 3 and the fourth substrate 4 are arranged on the propagation path of the first outgoing light beam 7 , and the first outgoing light beam 7 vertically enters the third substrate 3 and the fourth substrate 4 for the second splitting process. The second light beam (not shown in the figure) converted by the third substrate 3 and the second light beam (not shown in the figure) converted by the fourth substrate 4 propagate in opposite directions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com