Wire clamping device and dimming actuator

A clamping device and wire technology, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of reducing test efficiency and inconvenient fixing of wires, and achieve the effect of avoiding wire falling off, stably fixing, and ensuring test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the prior art, when the dimming actuator is connected to the external wire for testing, it needs to be pre-fixed or directly fixed by screwing the screw. After the test fails, the screw needs to be screwed again. It is easy to fix the wire, which reduces the test efficiency.

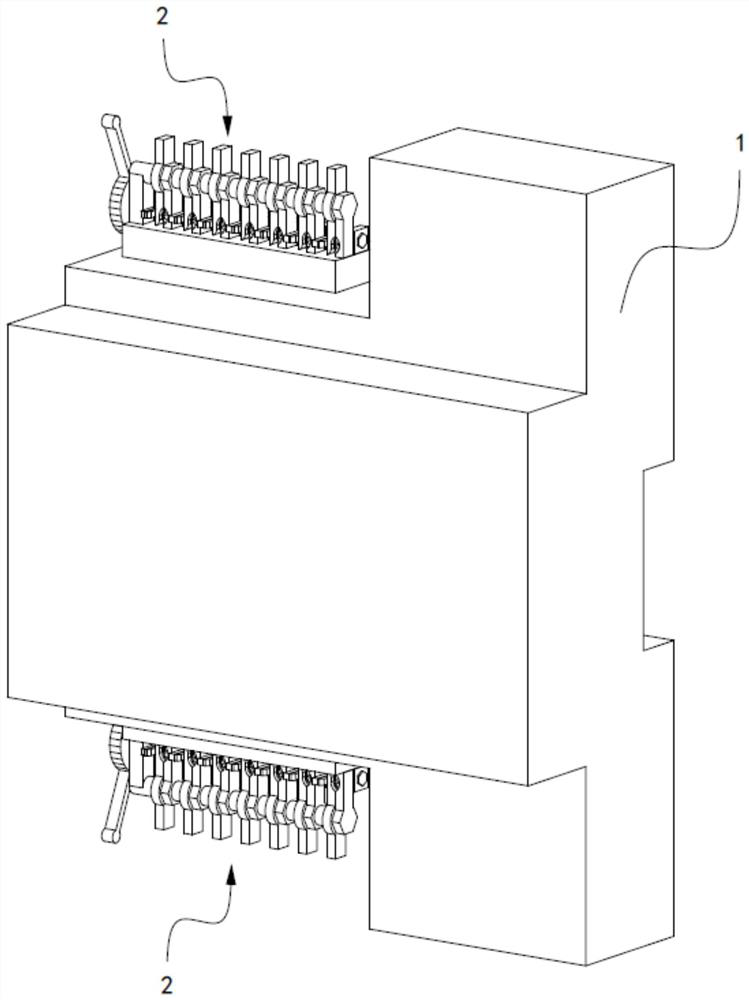

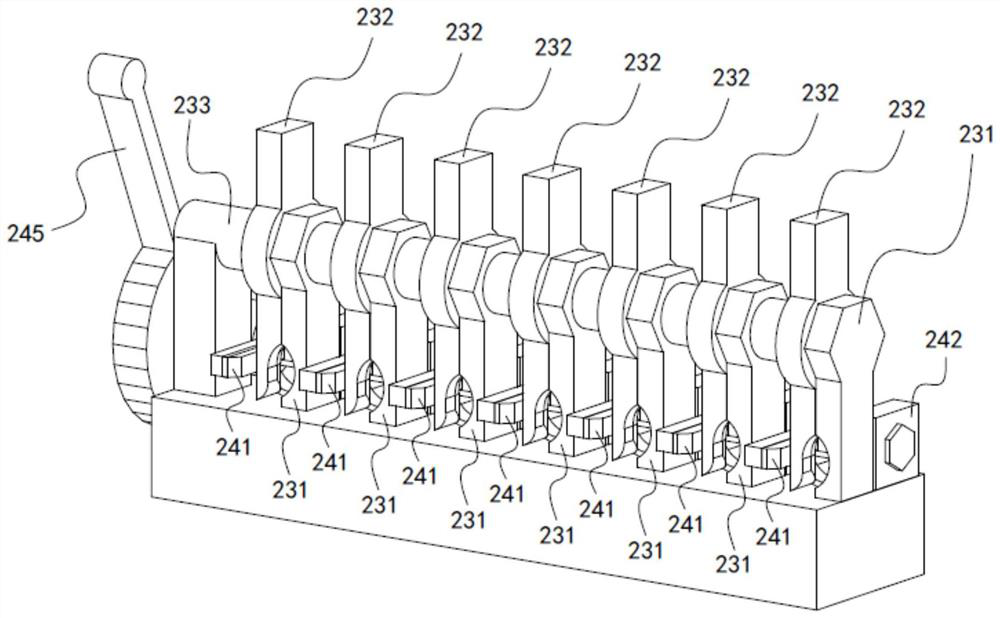

[0044] In order to solve the above problem, this embodiment provides a dimming actuator, such as Figure 1 to Figure 5 As shown, the dimming actuator 1 includes a wire clamping device 2, which can connect the externally inserted wire to the conductive terminal 21, and the wire clamping device 2 also includes a restraining mechanism 22, a positioning mechanism 23 and an actuating mechanism 23. Section 24, the restraint mechanism 22 is configured to restrain the wire inserted in the restraint mechanism 22, the restraint mechanism 22 is arranged in the restraint position, and the restraint position is selected so that the core of the exposed wire touches the conductive terminal 21, and the positio...

Embodiment 2

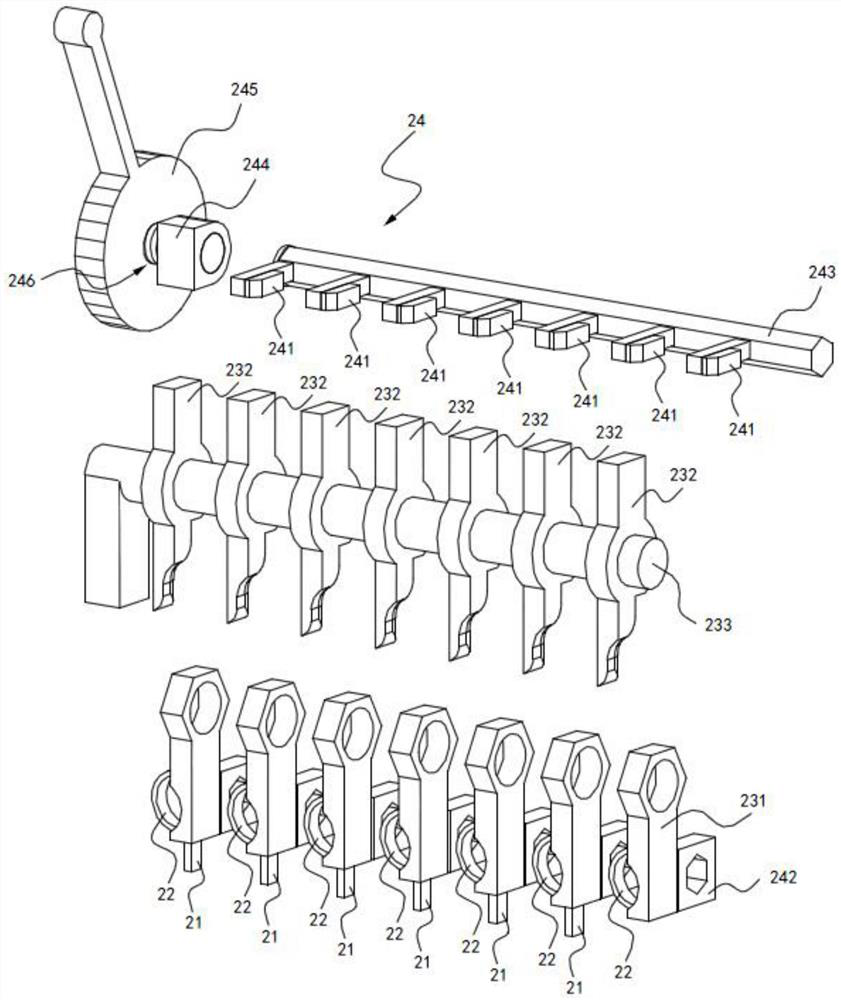

[0053] The difference between this embodiment and the first embodiment is that the structure of the actuating part 24 is different.

[0054] Since the handwheel 245 in the first embodiment moves together with the sliding rod 243 during the rotation process, if the dimming actuator needs to replace part of the wires, the wire clamping device 2 of the first embodiment cannot be released corresponding wire.

[0055] In order to solve the above problems, such as Image 6 and Figure 7 As shown, in this embodiment, the second positioning member 232 includes a base block 2322 and a positioning block 2323, the second connecting hole 2321 is provided on the base block 2322, and the base block 2322 is further provided with a diameter along the first rotating shaft 233. To the third connecting hole penetrating through the base block 2322, the second rotating shaft 246 passes through the third connecting hole and is exposed to the base block 2322. The positioning block 2323 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com