Non-dismantling bottom die floor plate for different-surface construction and construction method

A technology of floor slab and bottom formwork, which is applied in the processing of floor slabs, building materials, construction, etc., can solve the problem of slab thickness being restricted by the height of steel trusses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

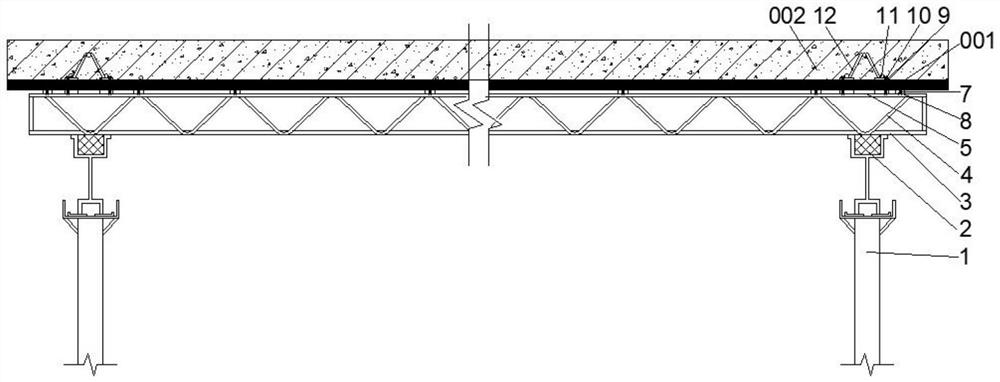

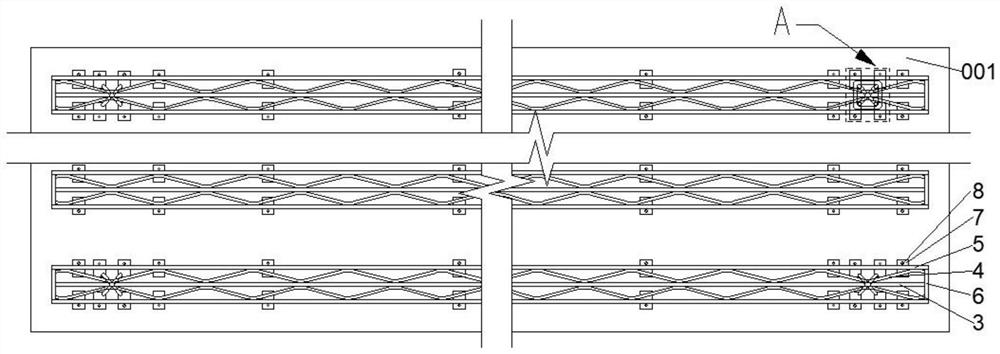

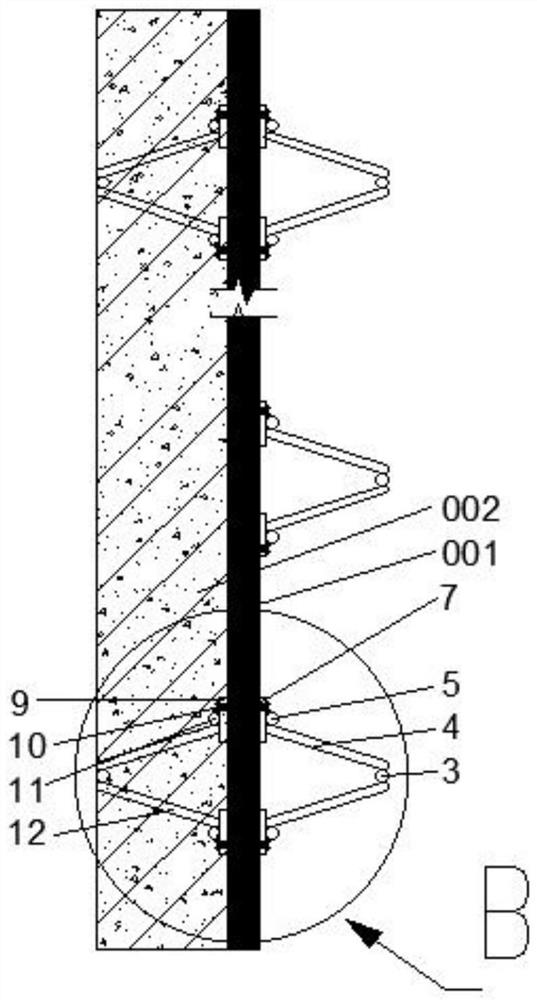

[0028] figure 1 It is a schematic diagram of the structure of the present invention. As shown in the figure, the transverse direction in this scheme is the width direction of the truss, the longitudinal direction is the length direction of the truss, and the height direction is the height direction when the truss is erected. Here It will not be repeated; the floor slab without dismantling of the bottom formwork constructed on different surfaces in this embodiment includes a bottom formwork 001, a load-bearing member and a hoisting assembly, and the hoisting assembly is installed on the top surface of the bottom formwork 001 and is used to lift the bottom formwork through a hoisting mechanism. 001 is sent to the preset position, and the load-bearing member is detachably installed on the bottom surface of the bottom mold 001 to form a support for the bottom mold 001; the cast-in-place covering layer and / or the prefabricated cover plate is formed to cover the top surface of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com