Solid-liquid separation device for heavy metal sewage treatment

A technology for sewage treatment and solid-liquid separation, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of inconvenient replacement of filter plates, inconvenient removal of filter plate sludge, frequent maintenance, etc., to achieve easy replacement and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

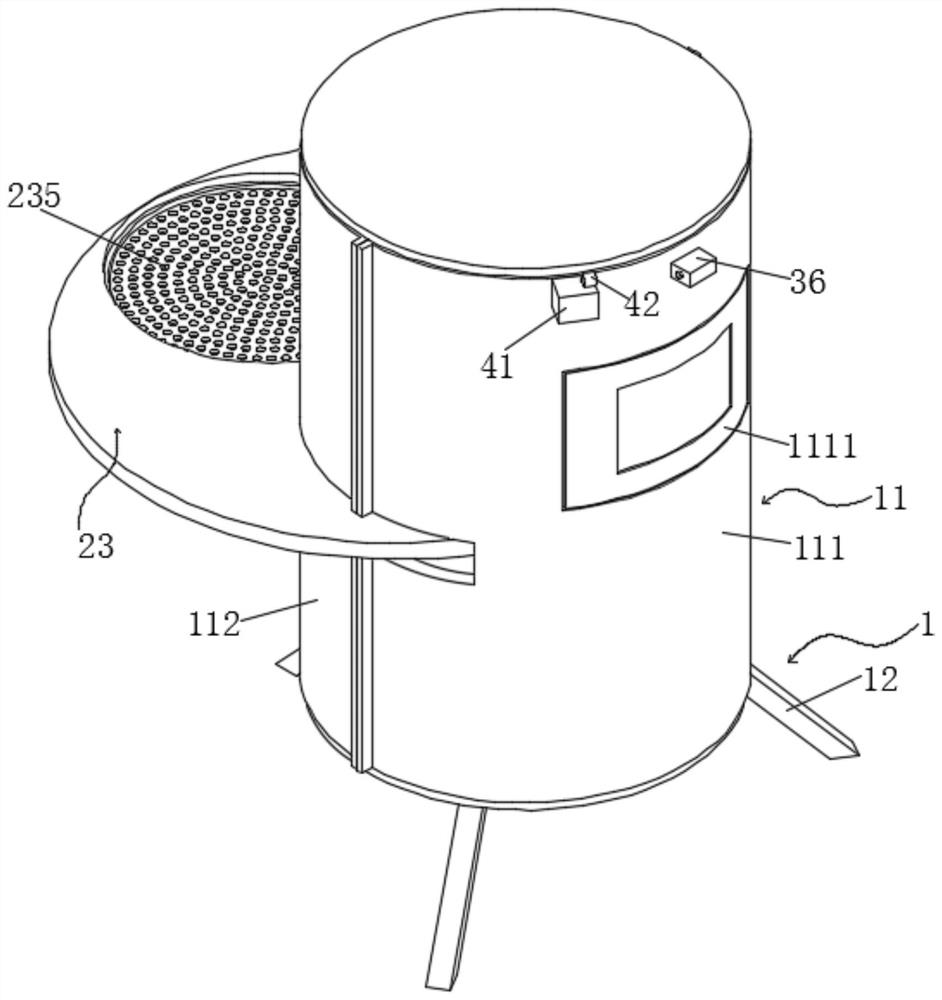

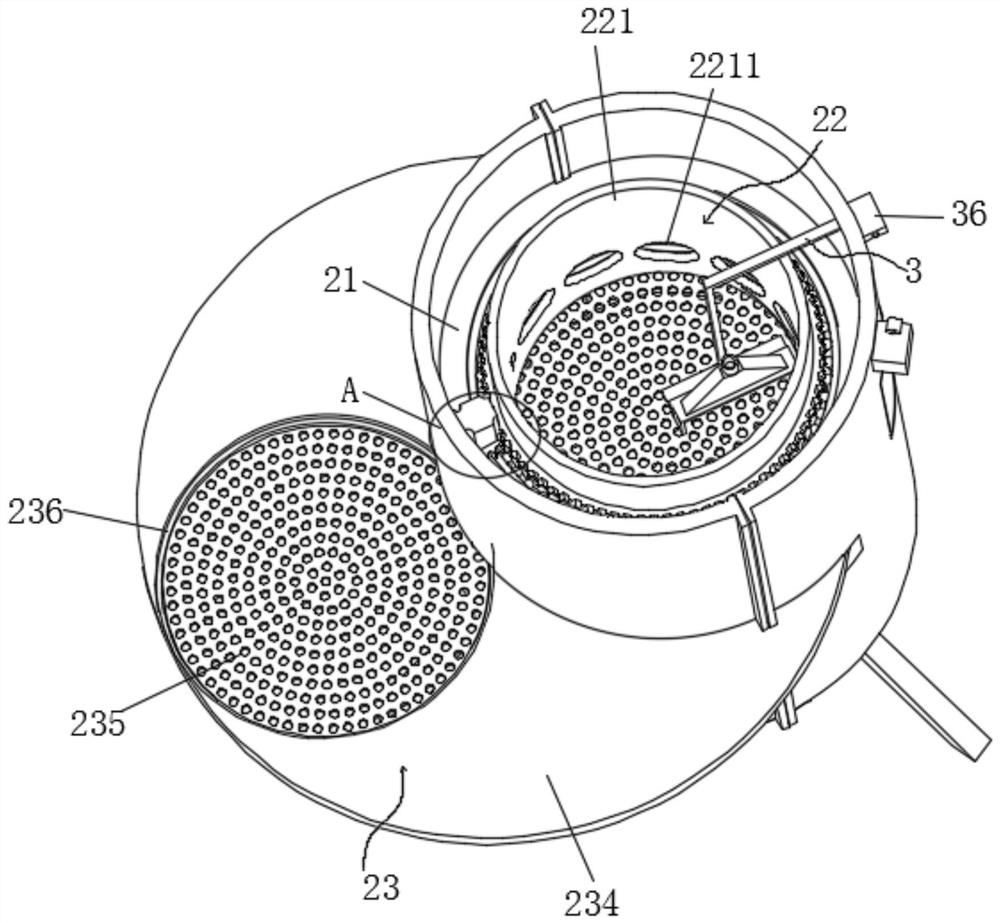

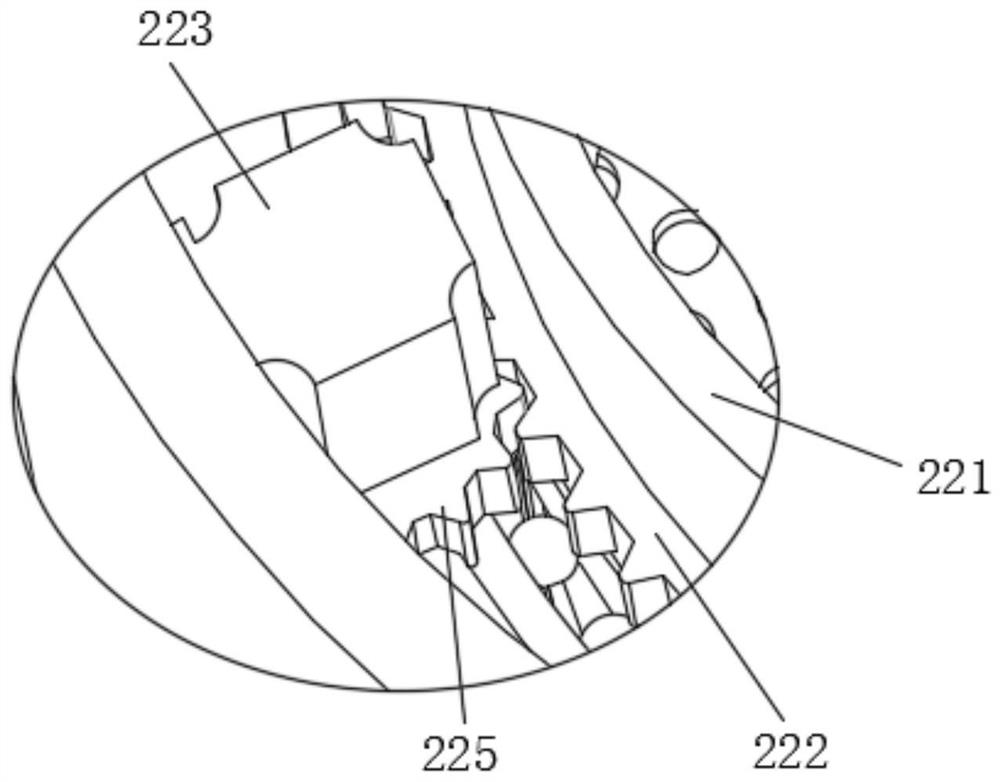

[0059] see Figure 1-Figure 7 , This application provides a solid-liquid separation device for heavy metal sewage treatment, including a support mechanism 1 , a filter mechanism 2 , a material suction mechanism 3 , a washing mechanism 4 and a water receiving mechanism 5 .

[0060] The support mechanism 1 is used to support and accommodate other mechanisms.

[0061] The filter mechanism 2 is arranged inside the support mechanism 1, and is used for receiving and filtering sewage, thereby realizing solid-liquid separation;

[0062] The feeding part of the suction mechanism 3 extends into the interior of the filter mechanism 2 for absorbing the sludge after solid-liquid separation;

[0063] The scrubbing mechanism 4 is arranged on the outer side of the filtering mechanism 2, and the water spraying part of the scrubbing mechanism 4 faces the filtering mechanism 2; the scrubbing mechanism 4 is used for washing a part of the filtering mechanism 2;

[0064] The water receiving mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com