Static electricity and filter bag combined type industrial dust removal equipment

A technology for dust removal equipment and filter bag dust removal, which is applied in electrostatic effect separation, lighting and heating equipment, and dispersed particle filtration. structure, the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

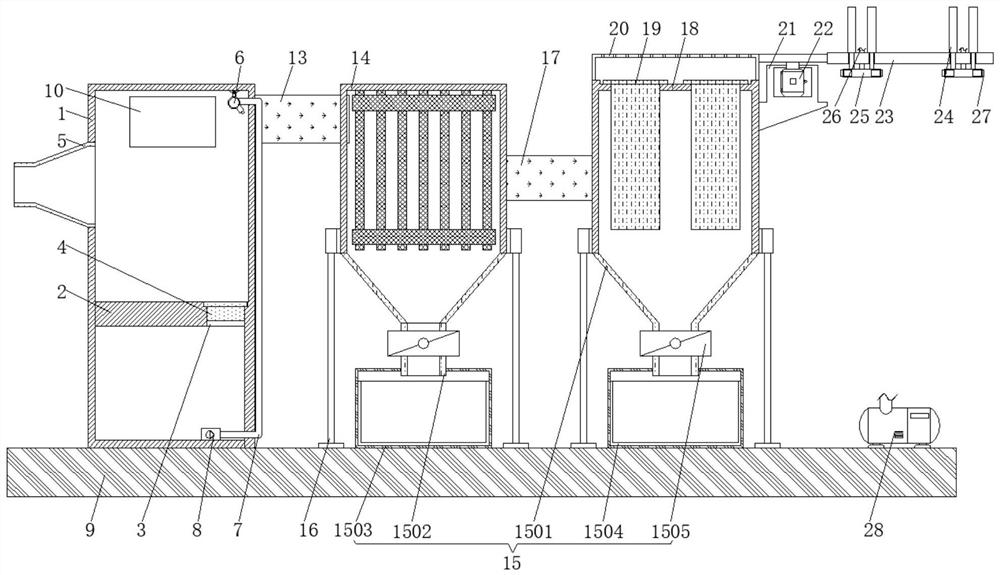

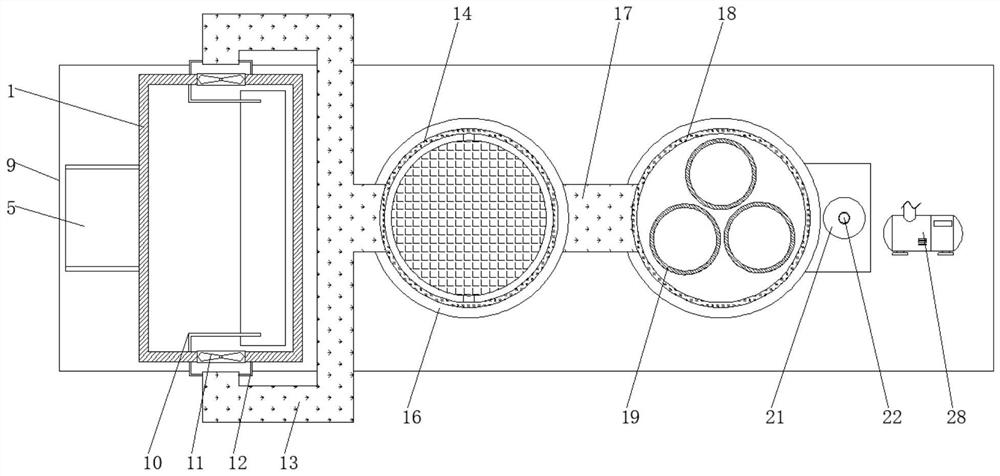

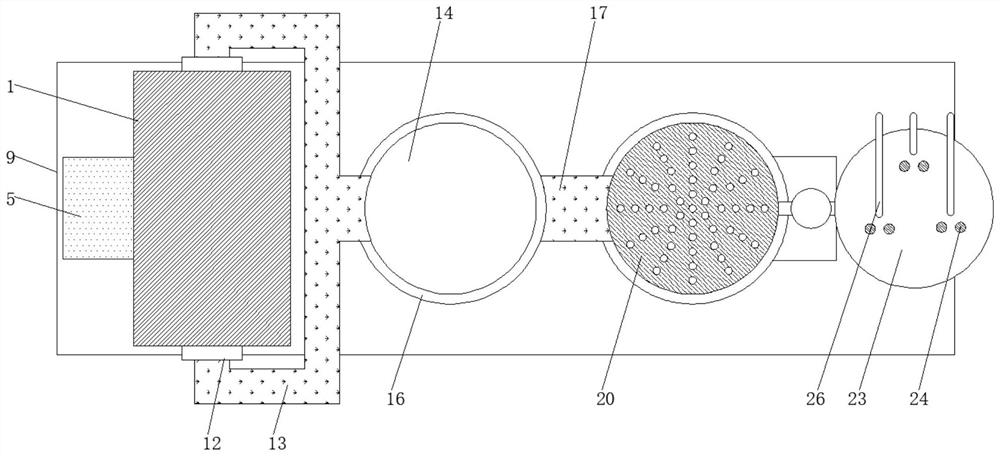

[0039] like figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown, a partition plate 2 is arranged in the cooling spray box 1, and a filter tank 3 is opened on the partition plate 2, and an air inlet 5 is opened on one side of the cooling spray box 1. The top is connected with a spray pipe 6 , and the spray pipe 6 is connected to the liquid pump 8 under the partition plate 2 through the circulation pipe 7 , and the cooling spray box 1 is arranged on the base 9 .

[0040] Specifically, the worker can use external extraction equipment or tools to clean the impurities filtered out on the partition plate 2 through the air inlet 5 , and at the same time, a drain faucet is provided at the bottom of one side of the cooling spray box 1 .

[0041] In a further embodiment, the filter sleeve 4 is clamped in the filter tank 3 , and the filter sleeve 4 is evenly provided with filter holes 401 .

[0042] Specifically, the filter sleeve 4 can block the impurities washed by t...

Embodiment 2

[0052] This embodiment is a further description of the above-mentioned embodiment. It should be understood that this embodiment includes all the foregoing technical features and will be further described in detail.

[0053] In a further embodiment, the dust collecting device 15 includes a dust collecting hopper 1501, and the dust collecting hopper 1501 is connected to the dust collecting box 1503 through a dust discharge pipe 1502, and an electric valve 1505 is connected to the dust discharge pipe 1502. A dust box 1504 is provided.

[0054] In a further embodiment, the outer side of the dust collecting box 1504 is provided with a sealing plate 29, and the sealing plate 29 is connected with the front side wall of the dust collecting box 1503 by screws.

[0055] Preferably, a sealing ring is provided at the connection between the sealing plate 29 and the dust collecting box 1503 , and the dust collecting box 1503 is arranged on the base 9 .

[0056] Specifically, the dust separ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap