Mold anti-adhesion device used after glue injection forming

An anti-adhesion and mold technology, which is applied in the field of anti-adhesion devices, can solve the problems of time-consuming cooling and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

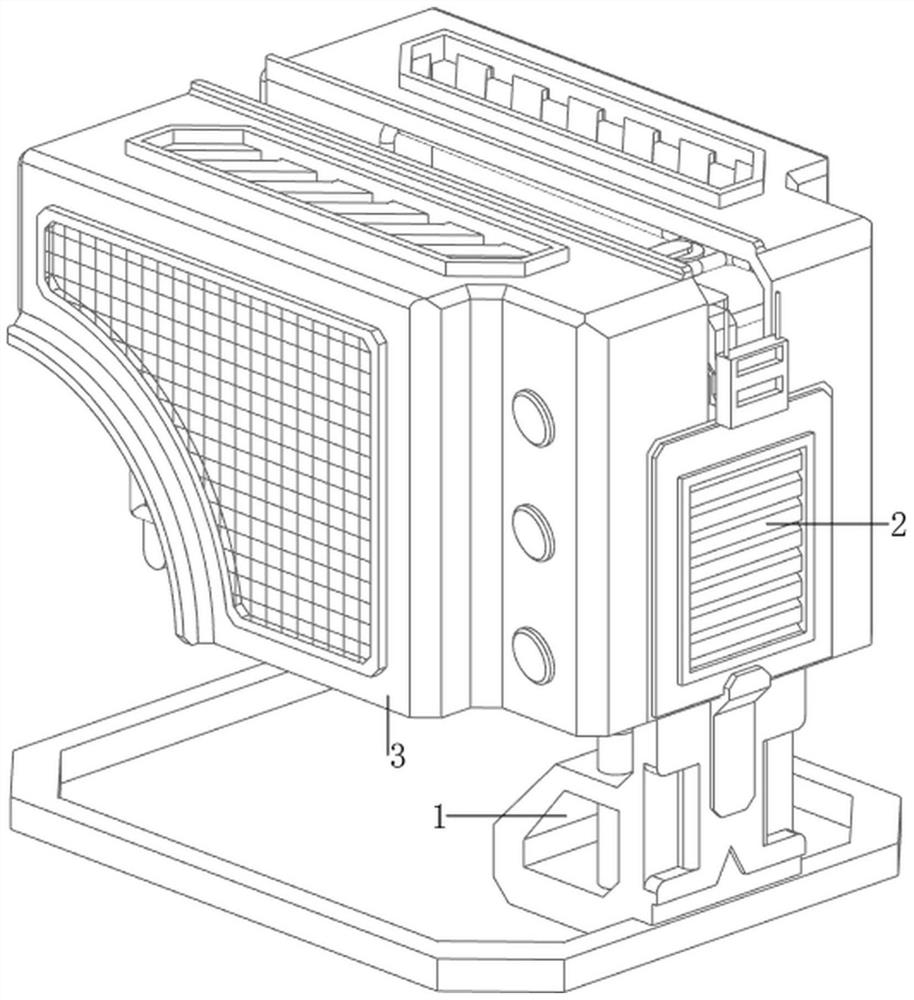

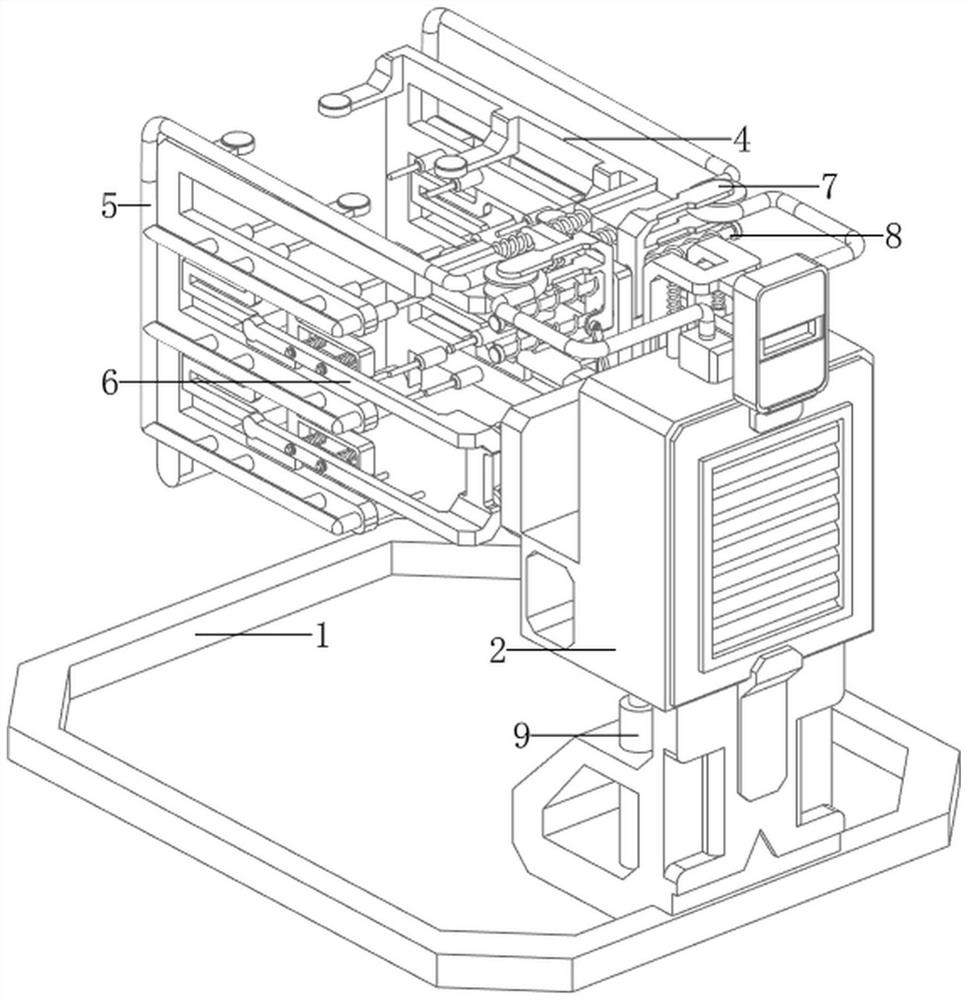

[0072] A mold anti-adhesion device after injection molding, now refer to Figure 1-2 , including a base frame 1, a mounting plate frame 2, a protective casing 3, a connection mechanism 4 and an anti-adhesion mechanism 5, a mounting plate frame 2 is placed on the front side of the upper part of the base frame 1, and a connecting mechanism 4 is installed on the mounting plate frame 2. A protective casing 3 is welded on the left and right sides of the plate frame 2 , and an anti-adhesion mechanism 5 is arranged between the mounting plate frame 2 , the protective casing 3 and the connecting mechanism 4 .

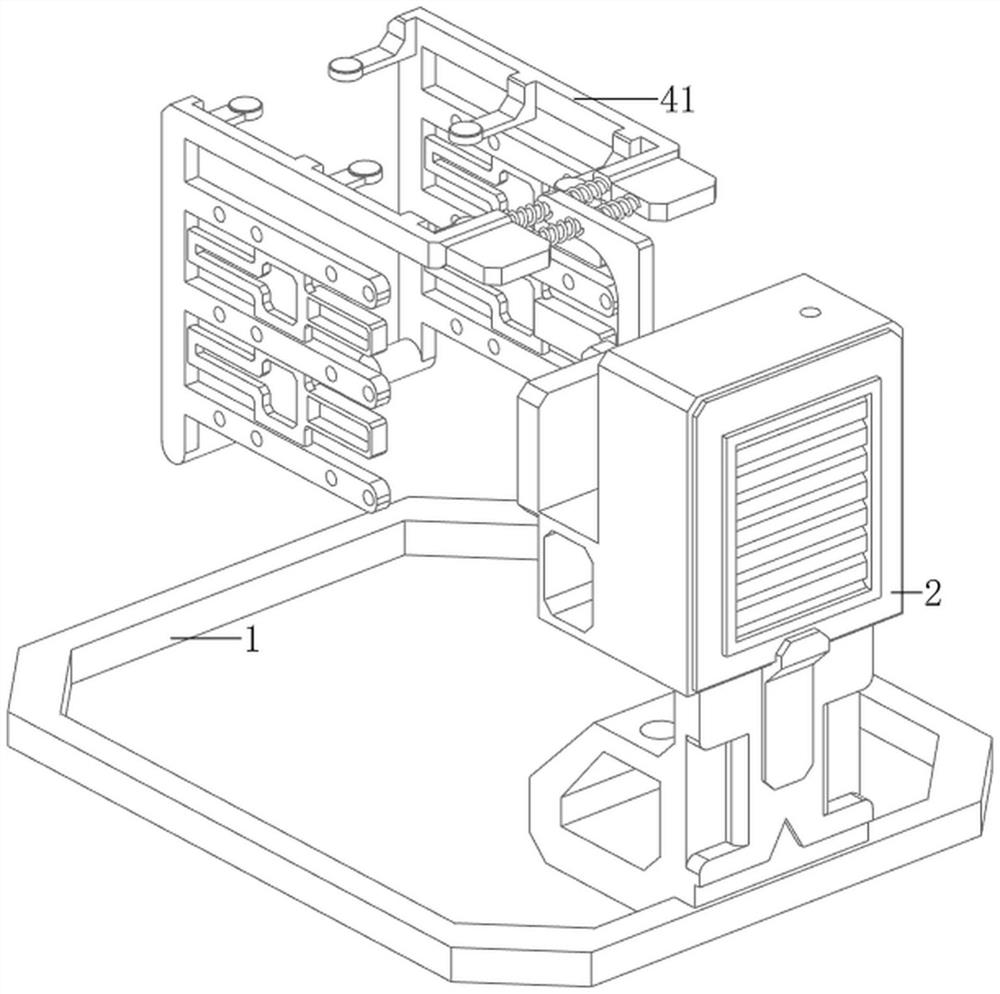

[0073] Reference now figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 9 , Figure 10 and Figure 11 , the connecting mechanism 4 includes a connecting frame 41, a first sliding rod 42 and a first spring 43, two first sliding rods 42 are welded on the left and right sides of the upper part of the rear side of the mounting plate frame 2, and th...

Embodiment 2

[0077] On the basis of Example 1, now refer to figure 2 , Figure 9 , Figure 10 , Figure 11 and Figure 12 , and also includes an ejection mechanism 6, the ejection mechanism 6 includes a first moving frame 61, a thimble 62, a first telescopic rod 63, a second spring 64, a second sliding rod 65 and a third spring 66, the mounting plate frame 2 Two first telescopic rods 63 are welded to the left and right rear sides, and there are four first telescopic rods 63. A first moving frame 61 is connected between the two first telescopic rods 63 on the same side. The first moving frame A second spring 64 is connected between the upper and lower sides of the front side and the first telescopic rod 63 on the same side. There are four second springs 64. The upper and lower sides of the first moving frame 61 are provided with ejector pins 62 on the rear side. There are two second sliding rods 65 on the upper and lower sides of the connecting frame 41. The second sliding rods 65 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com