Outer package clamping device

A clamping device and outer packaging technology, which is applied in the direction of workpiece clamping device, packaging sealing/fastening, packaging, etc., can solve the problems of poor anti-counterfeiting effect of the riveting structure, and achieve poor anti-counterfeiting effect, enhanced anti-counterfeiting, and difficulty in disassembly increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be noted here that, although the description of these embodiments is for helping understanding of the present invention, it does not constitute a limitation of the present invention.

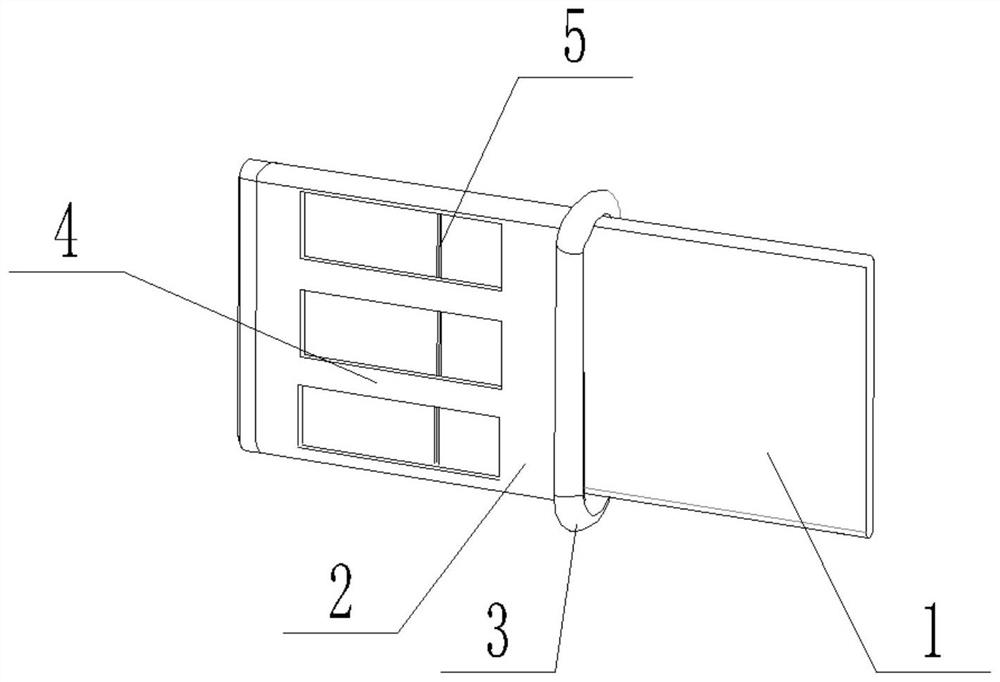

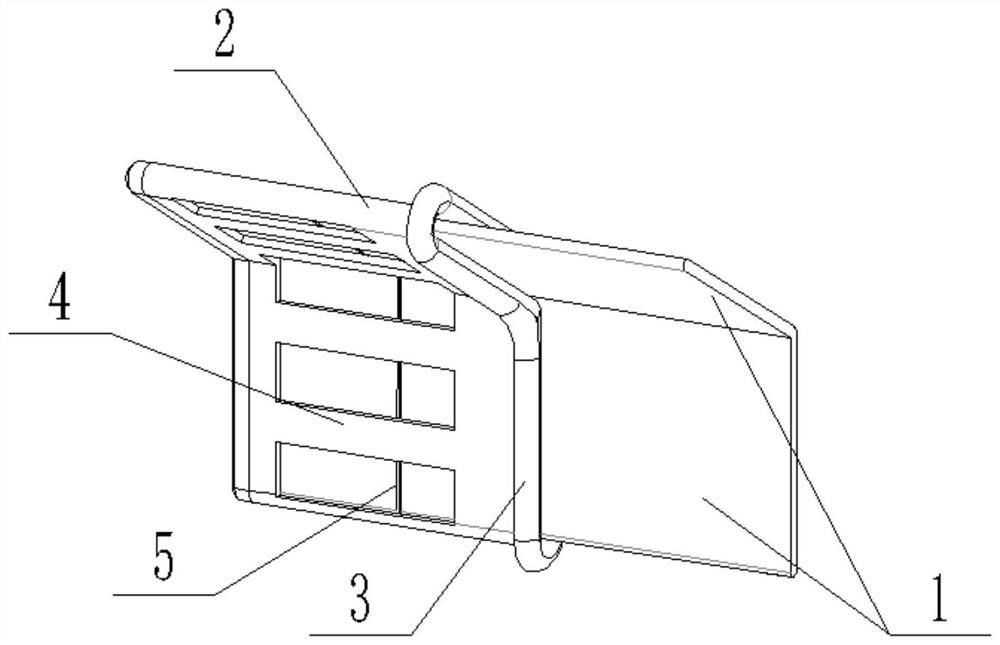

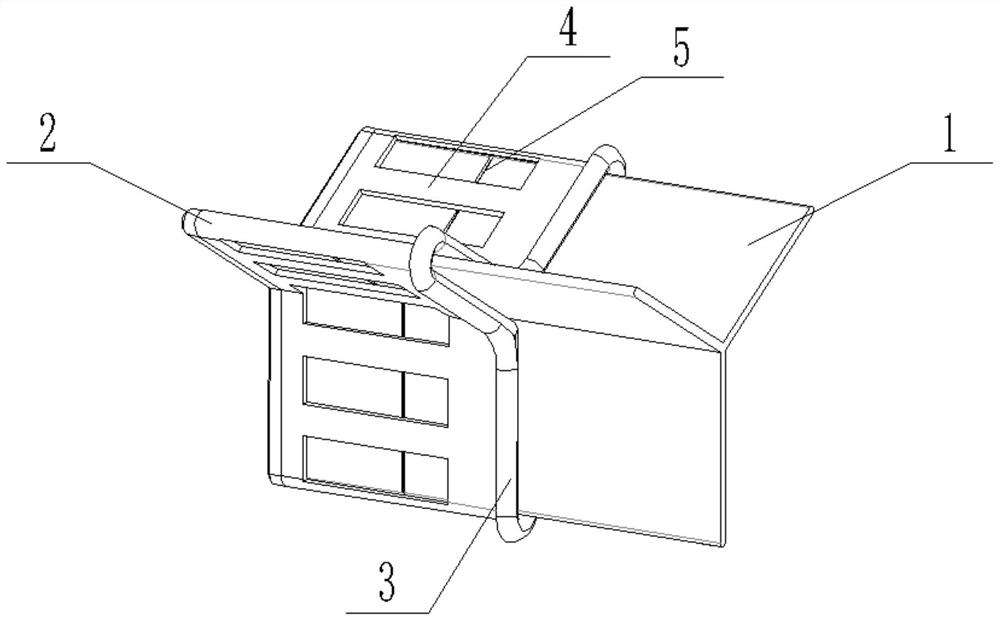

[0026] like figure 1 As shown, in the first embodiment of the outer packaging clamping device provided by the present invention, it includes a rivet sleeve and a rivet core located in the rivet sleeve, the rivet core includes a rivet core plate 1, and the rivet sleeve is provided with There is a hollow rivet sleeve plate 2 matched with the rivet plate 1, one end of the rivet plate 1 is connected with the bottom end of the rivet sleeve plate 2, and the other end of the rivet plate 1 leaks out of the rivet sleeve plate 2; The top edge of the rivet sleeve plate 2 is provided with a raised edge 3, and a plurality of foldable strips 4 are arranged on the rivet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com