Hollow shutter glass control mechanism convenient to operate

A louver glass and control mechanism technology, applied in the direction of power control mechanism, wing fan control mechanism, building components, etc., can solve the problems of heavy workload and slow maintenance work, and achieve convenient operation, convenient centralized processing, and maintenance efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

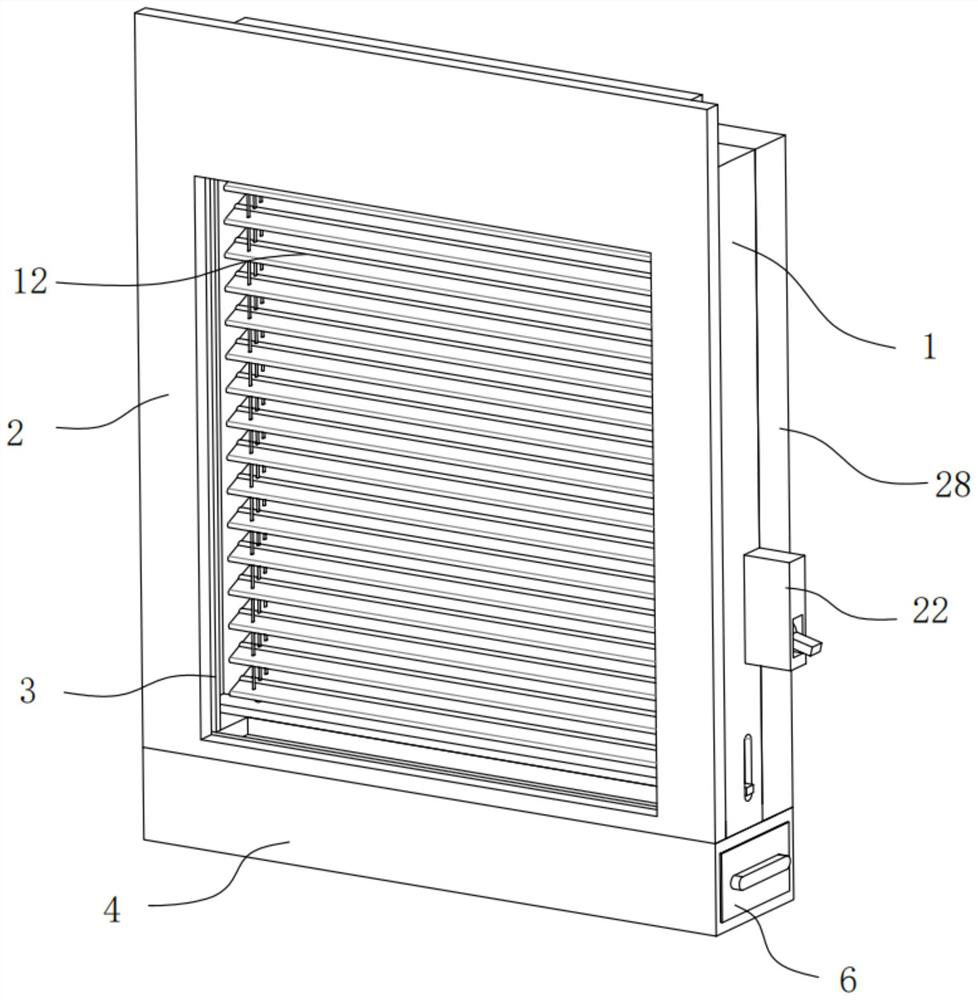

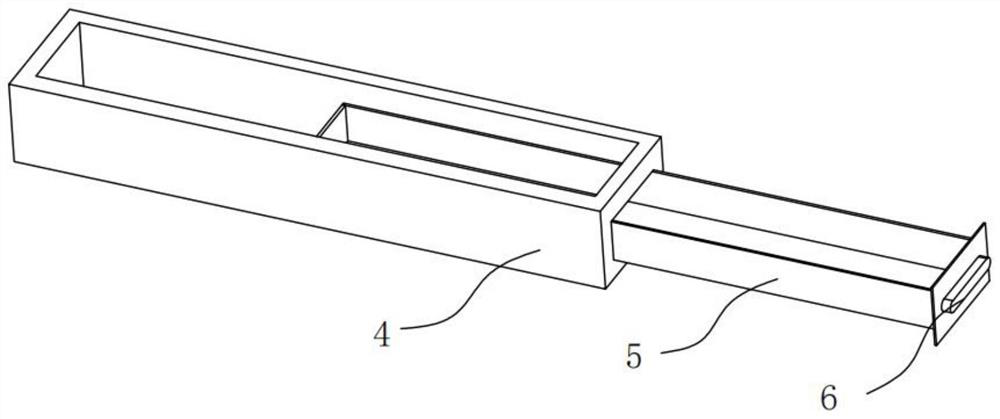

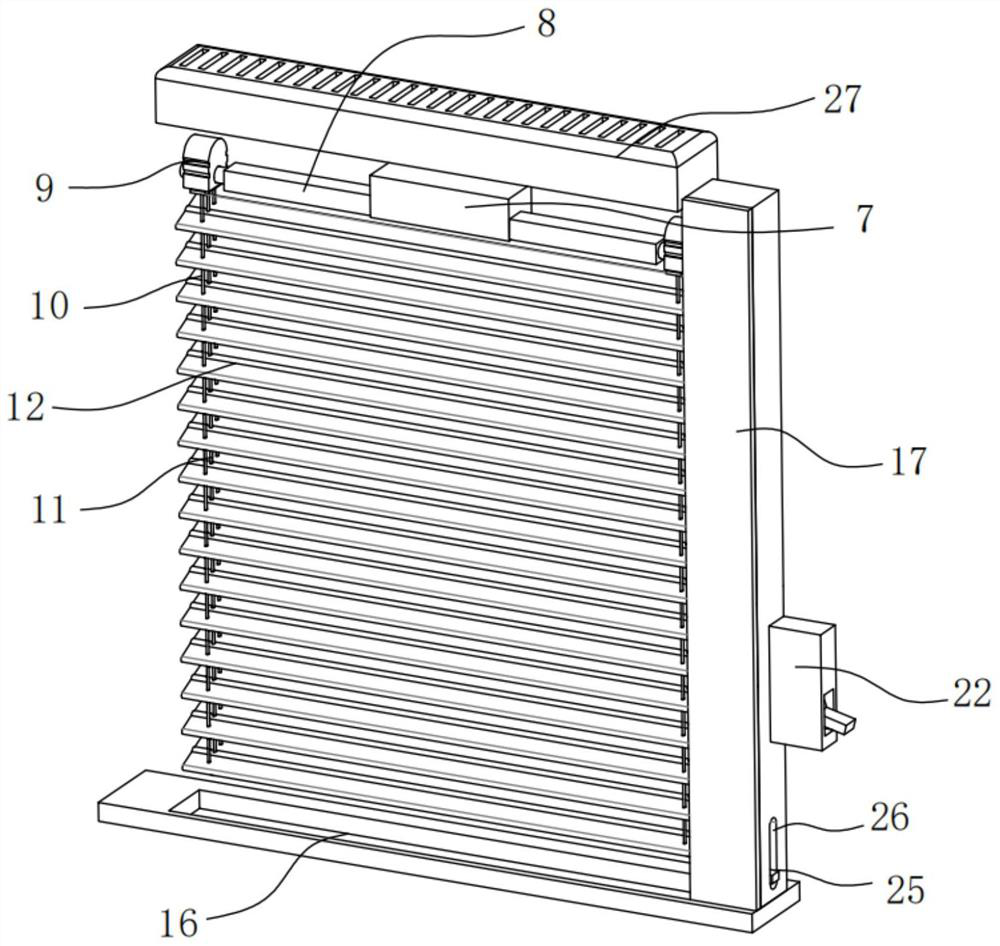

[0027] Please refer to figure 1 , figure 2 , image 3 , Figure 4 ,in, figure 1 It is a schematic structural diagram of the first embodiment of a control mechanism for hollow louver glass with convenient operation provided by the present invention; figure 2 A schematic structural diagram of a collection box of a control mechanism for hollow louver glass provided by the present invention; image 3 A schematic diagram of the internal structure of a control mechanism for hollow louver glass with convenient operation provided by the present invention; Figure 4 It is a schematic structural diagram of the inside of the shaking box of the control mechanism for hollow louver glass provided by the present invention. An easy-to-operate hollow shutter glass control mechanism includes: a main frame 1;

[0028] Panel 2, the panel 2 is fixedly installed on the front side surface of the main frame 1, and the interior of the panel 2 is provided with a glass slot 3 for installing the ...

no. 2 example

[0042] see Figure 5 , Figure 5 It is a schematic structural diagram of the second embodiment of a control mechanism for hollow louver glass with convenient operation provided by the present invention. Based on an easy-to-operate hollow shutter glass control mechanism provided in the first embodiment of the present application, the second embodiment of the present application proposes another easy-to-operate hollow shutter glass control mechanism. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0043] Specifically, the easy-to-operate hollow shutter glass control mechanism provided by the second embodiment of the present application is different in that, in the easy-to-operate hollow shutter glass control mechanism, the outer side of the installation sleeve 28 is fixedly installed with Shock pad 29.

[0044] The shock-absorbing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com