Installation method of sintering cylinder type mixing machine

An installation method and mixer technology, which are applied in the direction of measuring devices, measuring instruments, instruments, etc., can solve the problems of high labor intensity of construction personnel, long installation time, and large tonnage of cylindrical mixers, so as to improve installation efficiency and installation efficiency. Accuracy, easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

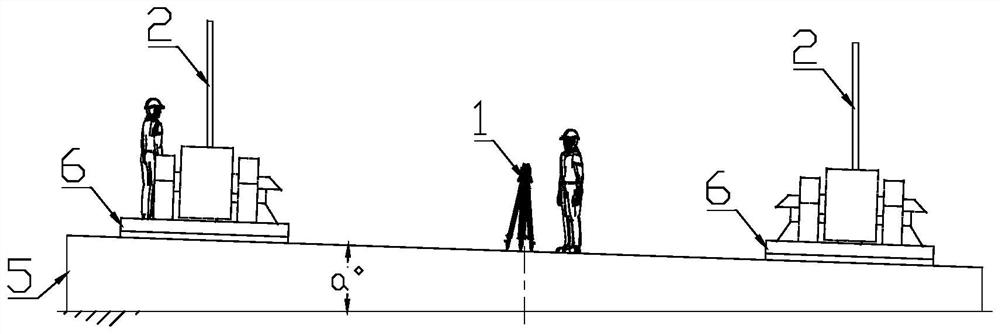

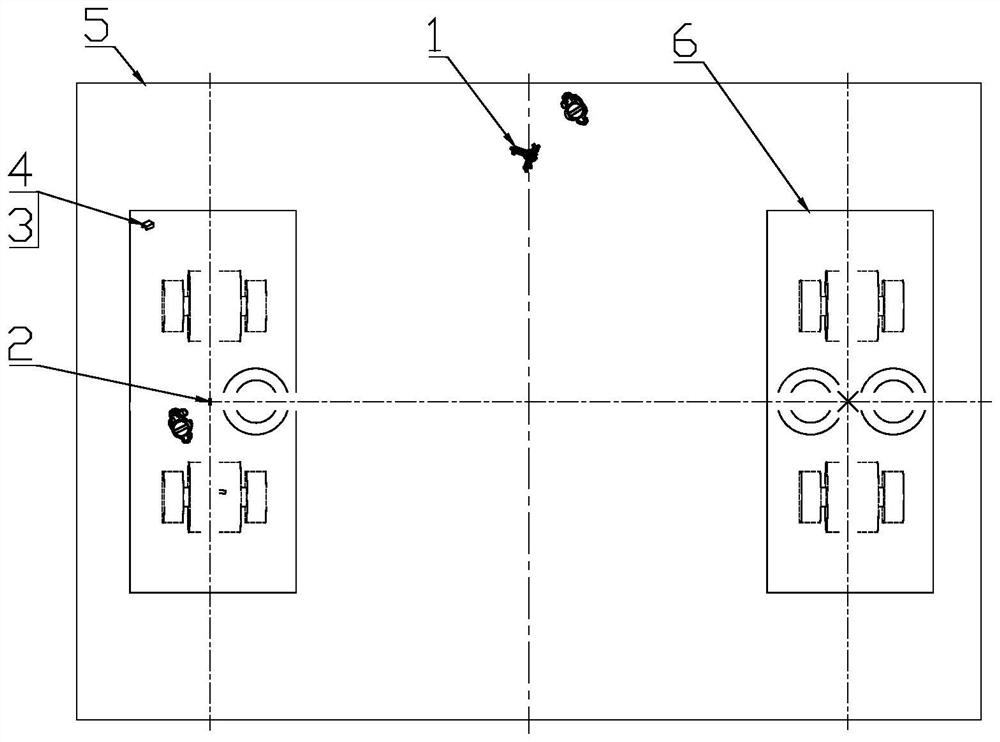

[0025] See figure 1 , figure 2 As shown, the installation method of a sintered cylindrical mixer involved in the present invention includes the following steps:

[0026] 1) Fabrication of foundation 5: According to the design requirements, pour the installation foundation 5 with an inclined plane, wherein the inclination angle of the inclined plane = the equipment installation inclination angle a°;

[0027] 2) Line drawing: draw the center line of the foundation 5, and at the same time draw the center lines of the two mounting bases 6 on the foundation 5 according to the installation drawing of the sintered cylindrical mixer to be installed, and draw the center lines of the two mounting bases 6 on the base 5, and at the center of the mounting base 6 Point preset expansion bolt;

[0028] 3) Pre-installed mounting base 6: Place the two mou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap