Automatic white edge repairing device for mobile phone tempered film

An automatic repair and tempered film technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of complicated process, inability to repair white edges, low efficiency of white edge repair, etc., and achieve the effect of eliminating white edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

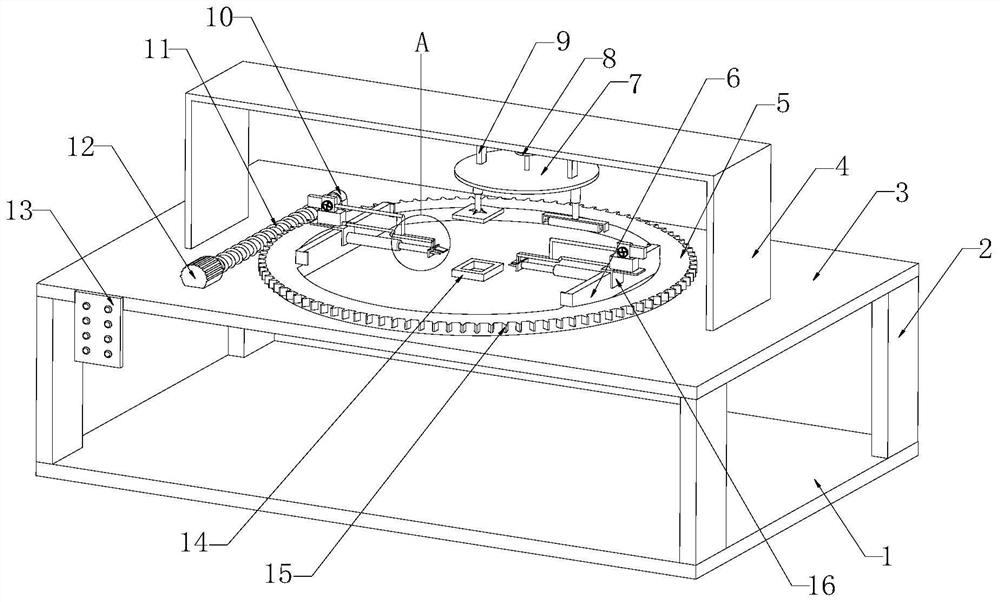

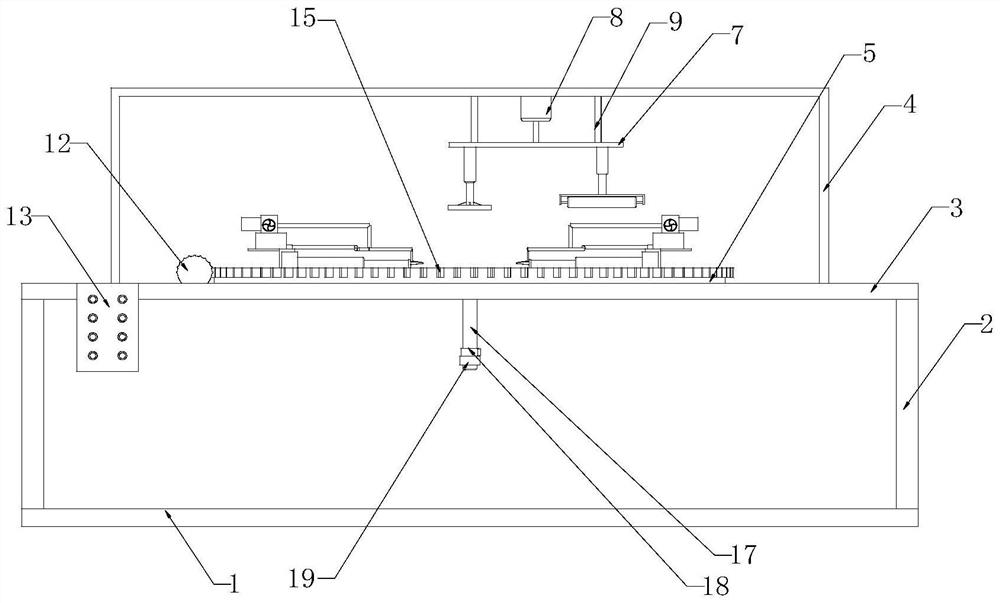

[0036] like Figure 1 to Figure 7 As shown, the embodiment of the present invention provides an automatic white edge repairing device for a mobile phone tempered film, comprising a base 1 and a mounting plate 3 arranged directly above the base 1, the mounting plate 3 is mounted with a working component, and the mounting plate A bracket 4 is fixedly installed on the top outer wall of 3, and a fixed component is installed between the bracket 4 and the base 1;

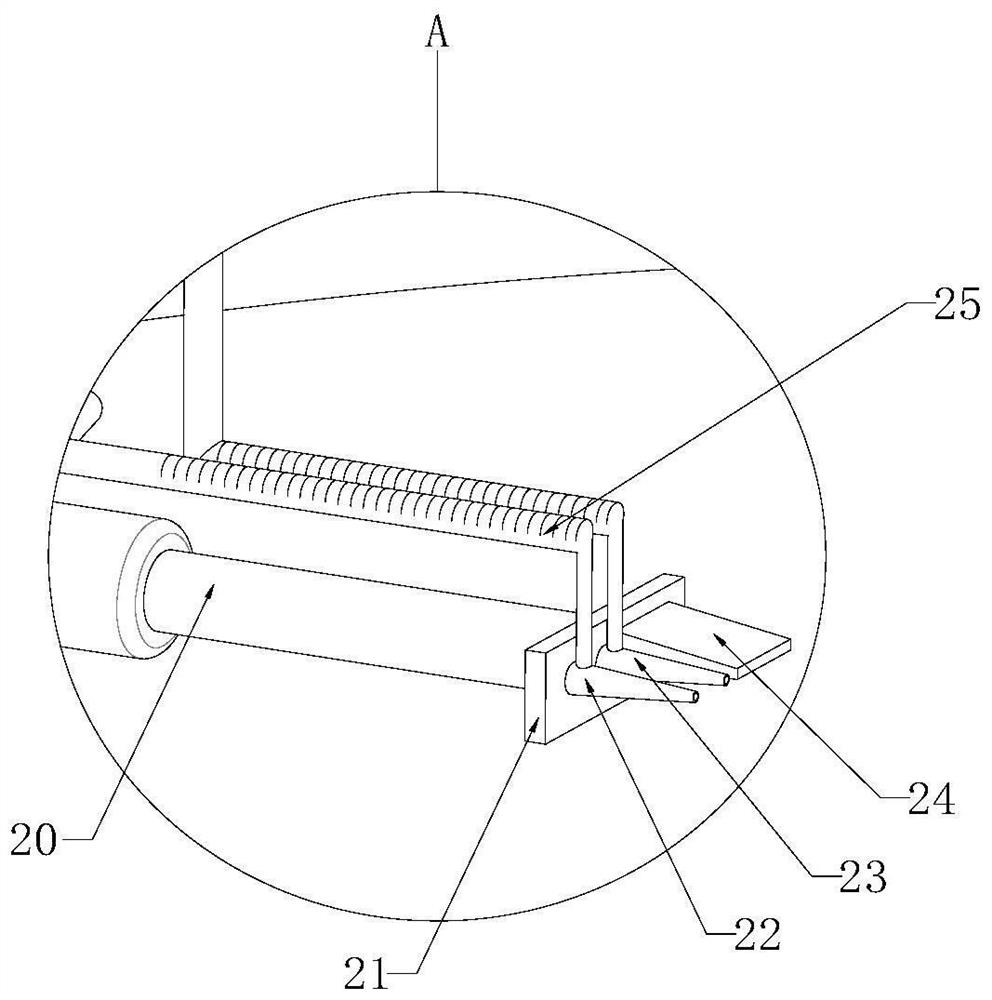

[0037]The working assembly includes a rotating carrier plate 5 arranged above the mounting plate 3, and guide rails 6 are fixedly installed on both inner ends of the rotating carrier plate 5, and matching electric sliders 16 are installed on the two guide rails 6. A horizontally arranged electric telescopic rod 1 20 is fixedly installed on the outer wall of one side of the electric sliding block 16 close to each other, and the end of the extension rod of the electric telescopic rod 1 20 is fixedly installed with an instal...

Embodiment 2

[0054] like Figure 8-9 As shown, this embodiment provides another automatic white edge repairing device for mobile phone tempered film. Compared with the first embodiment, this embodiment is provided with a locking component on the side of the bracket 4 close to the operation turning plate 7, and the lock The tightening assembly includes a side plate 36 fixedly installed on the bracket 4 , and a bracket 41 is fixedly installed on an outer wall of the side plate 36 close to the operation turning plate 7 .

[0055] Further, a sliding rod 39 is slidably connected to the inner wall of the support cylinder 41 , and a ball head block 38 is fixedly installed at one end of the sliding rod 39 close to the operation turning plate 7 , and a compression block 38 is fixedly installed between the ball head block 38 and the support cylinder 41 . In the spring 40 , an arc-shaped clamping slot 37 which matches with the ball head clamping block 38 is opened on one side of the circumferential o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com