Auxiliary device for conveniently and accurately controlling increment of coating tackifier

An auxiliary device and thickening agent technology, which is applied in the direction of feeding device, transportation and packaging, cleaning method and utensils, etc., can solve the problems of air bubbles and affecting the measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

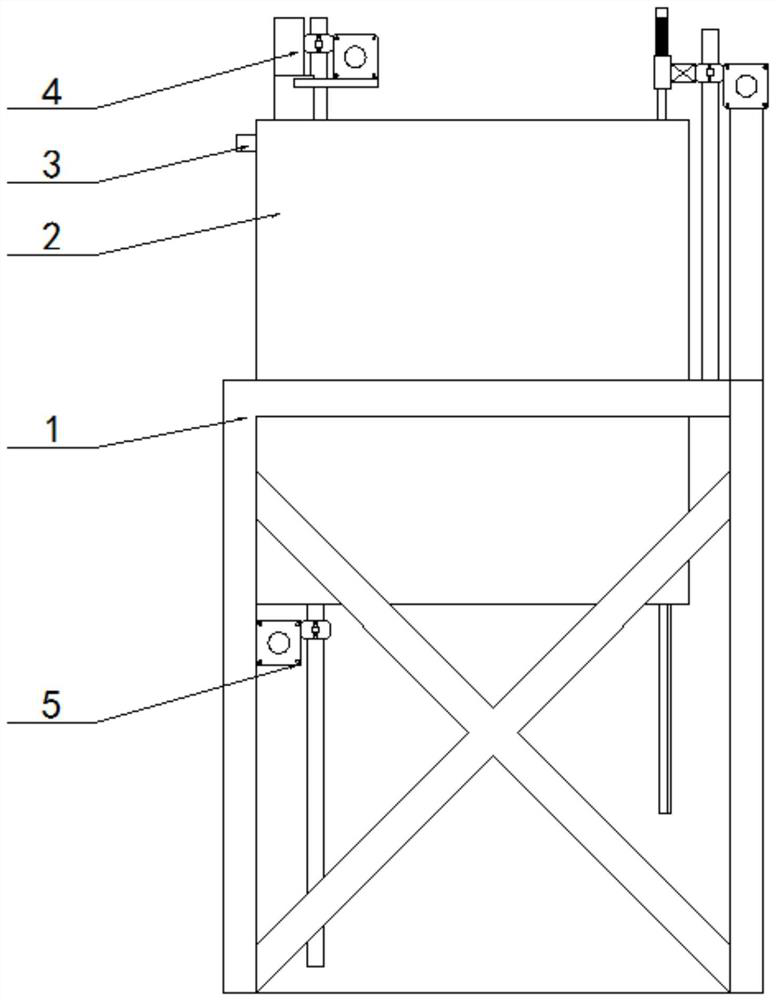

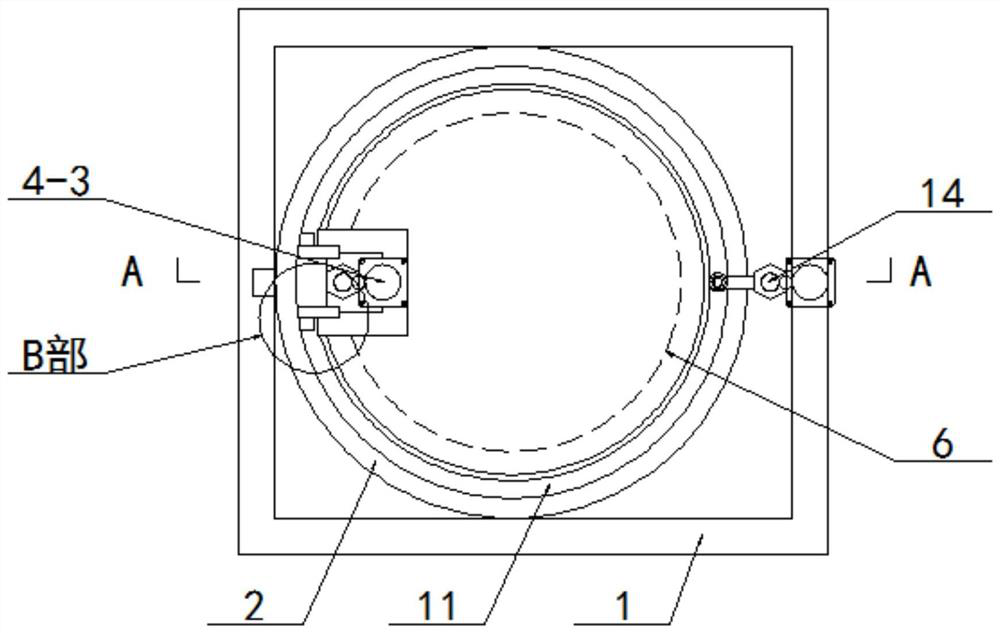

[0039] like figure 1 , 2 As shown, this embodiment includes a bracket 1 and a barrel 2, wherein the barrel 2 is fixedly arranged on the bracket 1, and the upper end of the left side wall of the barrel 2 is fixed with a feeding pipe 3, which also includes:

[0040] The feeding part 4 and the feeding part 4 are arranged in the barrel 2, and the inlet end of the feeding part 4 and the outlet end of the feeding pipe 3 are arranged through;

[0041] The quantitative part 5, the quantitative part 5 is arranged in the barrel 2, and the quantitative part 5 is arranged below the feeding part 4;

[0042] With the above design scheme, during quantitative feeding, the external raw materials are fed into the feeding part 4 through the feeding pipe 3, and then the raw materials are fed into the feeding part 4 through the feeding part 4, and the feeding part 5 is used to adjust the feeding cylinder 2. The volume in the barrel 2 is controlled, and the single filling amount in the barrel 2 i...

Embodiment 2

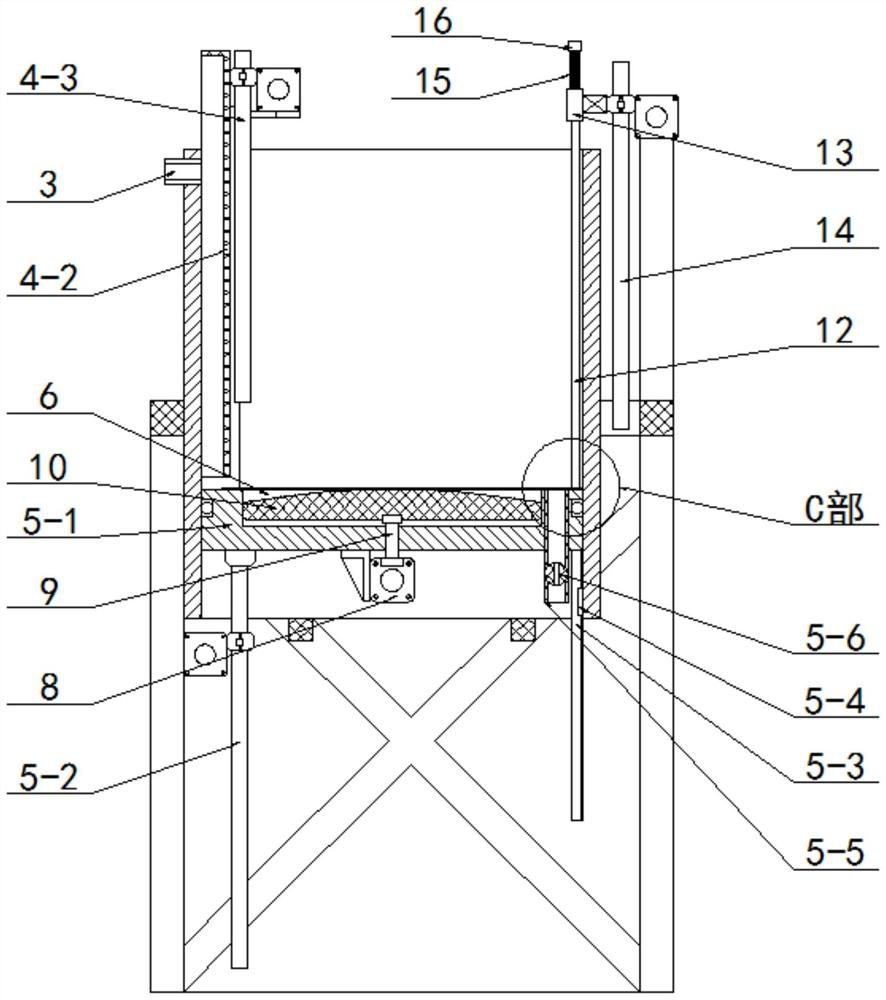

[0044] like figure 2 , 3 , 5, on the basis of the above-mentioned embodiment 1, the quantitative part 5 includes:

[0045] The bearing seat 5-1, the bearing seat 5-1 is movably arranged in the barrel 2;

[0046] Quantitative electric push rod 5-2, the quantitative electric push rod 5-2 is fixed on the bracket 1 by screws, and the output end of the quantitative electric push rod 5-2 passes through the lower port of the barrel 2, and is fixed by screws on the lower surface of the carrier 5-1;

[0047] Guide slider 5-3, the guide slider 5-3 is fixed on the lower surface of the bearing seat 5-1 by screws;

[0048] Guide slide rail 5-4, the guide slide rail 5-4 is fixed on the lower end of the inner side wall of the barrel 2 by screws, and the guide slide block 5-3 is slidably arranged on the guide slide rail 5-4;

[0049] The discharge pipe 5-5, the discharge pipe 5-5 is fixed on the bearing seat 5-1, and the upper port of the discharge pipe 5-5 is flush with the upper surfac...

Embodiment 3

[0052] like figure 2 , 3 , 5, on the basis of the above-mentioned embodiment 2, the lower surface of the bearing seat 5-1 is fixed with a vibration motor 8 by screws, and the upper surface of the bearing seat 5-1 is provided with a buffer groove 6, buffering The top of the groove 6 is covered with a waterproof membrane 7, and the side of the waterproof membrane 7 is glued and fixed on the upper surface of the bearing seat 5-1, and a vibration plate 10 is arranged in the buffer slot 6, and the output shaft of the vibration motor 8 passes through. A transmission rod 9 is fixed with screws, and after the upper end of the transmission rod 9 passes through the bearing seat 5-1, it is fixed on the lower surface of the vibration plate 10 by screws, and the upper surface of the vibration plate 10 is convexly arranged on a spherical surface;

[0053] With the above design scheme, after the raw materials are fed into the barrel 2 and the raw materials are stacked on the bearing seat 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com