Welding limiting support for automobile metal structure manufacturing

A technology of metal structures and limit brackets, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of adaptive adjustment of automotive metal parts, high investment costs, and poor versatility, and achieve cost savings and versatility Strong and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

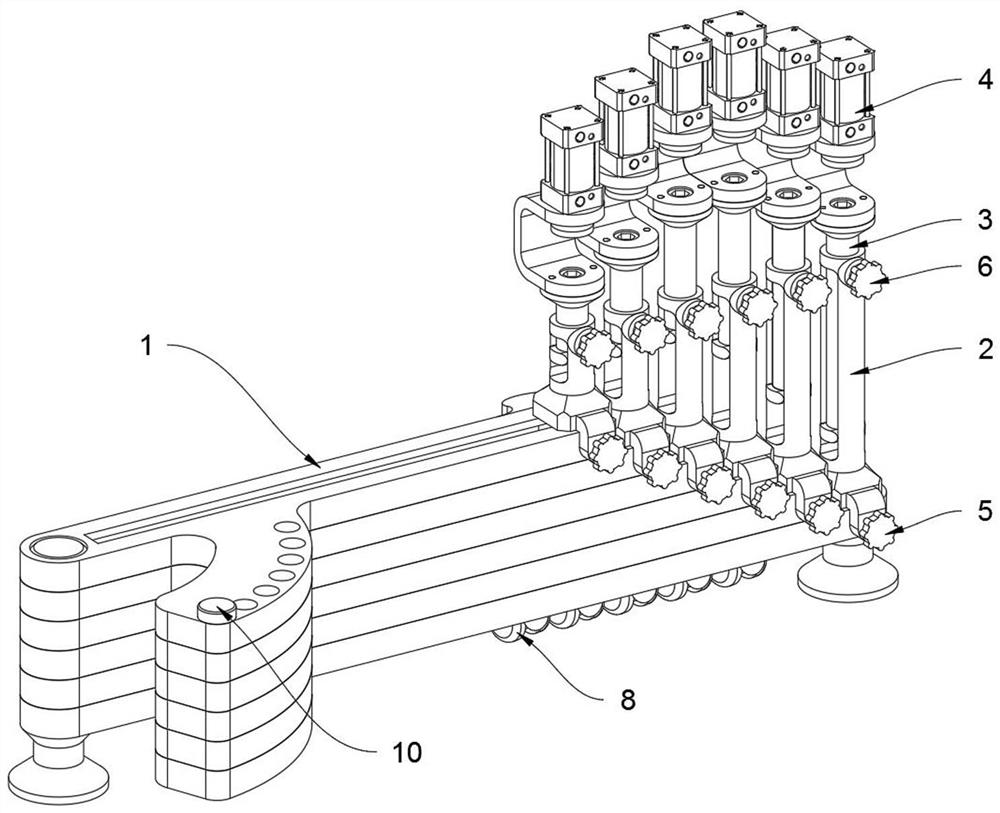

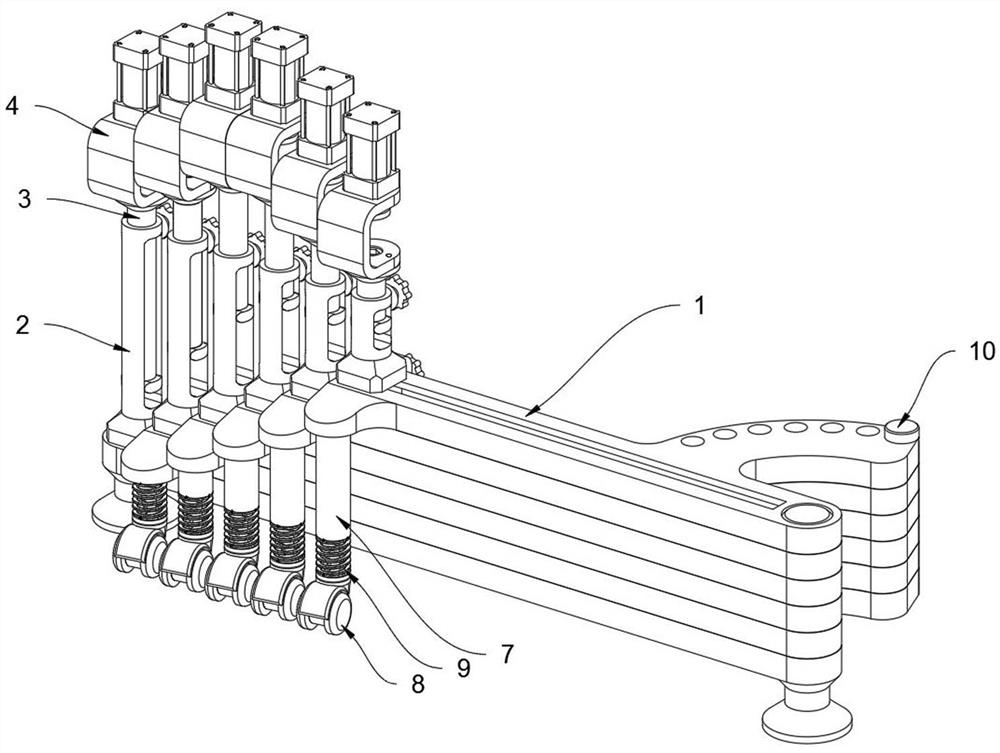

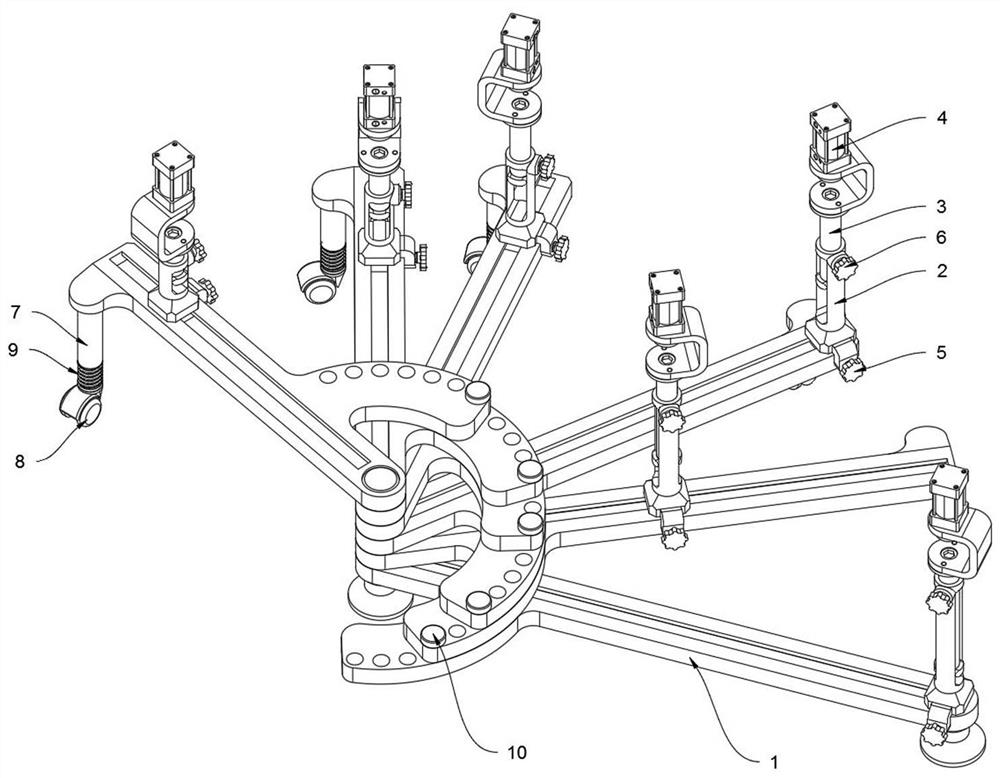

[0034] Please refer to Figure 1 to Figure 8 :

[0035] The invention proposes a welding limit bracket for automobile metal structure manufacturing, comprising: a rail frame 1; a total of six rail frames 1 are arranged in a row up and down, and the six rail frames 1 are connected to each other, and the six rail frames are 1. The length is in a state of decreasing from bottom to top; the rail frame 1 is rotatably connected with the two adjacent rail frames 1 up and down, and the rail frame 1 is provided with an arc-shaped plate 102 on one side, and the top of the arc-shaped plate 102 is provided with a slider A1021. The bottom of the shaped plate 102 is provided with a chute B1022, the top slider A1021 of the arc-shaped plate 102 is slidably connected to the bottom chute B1022 of the other arc-shaped plate 102, and the rotation angle between the adjacent upper and lower rail frames 1 is 0~60° , according to the different metal parts of the automobile to be welded, the five rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com