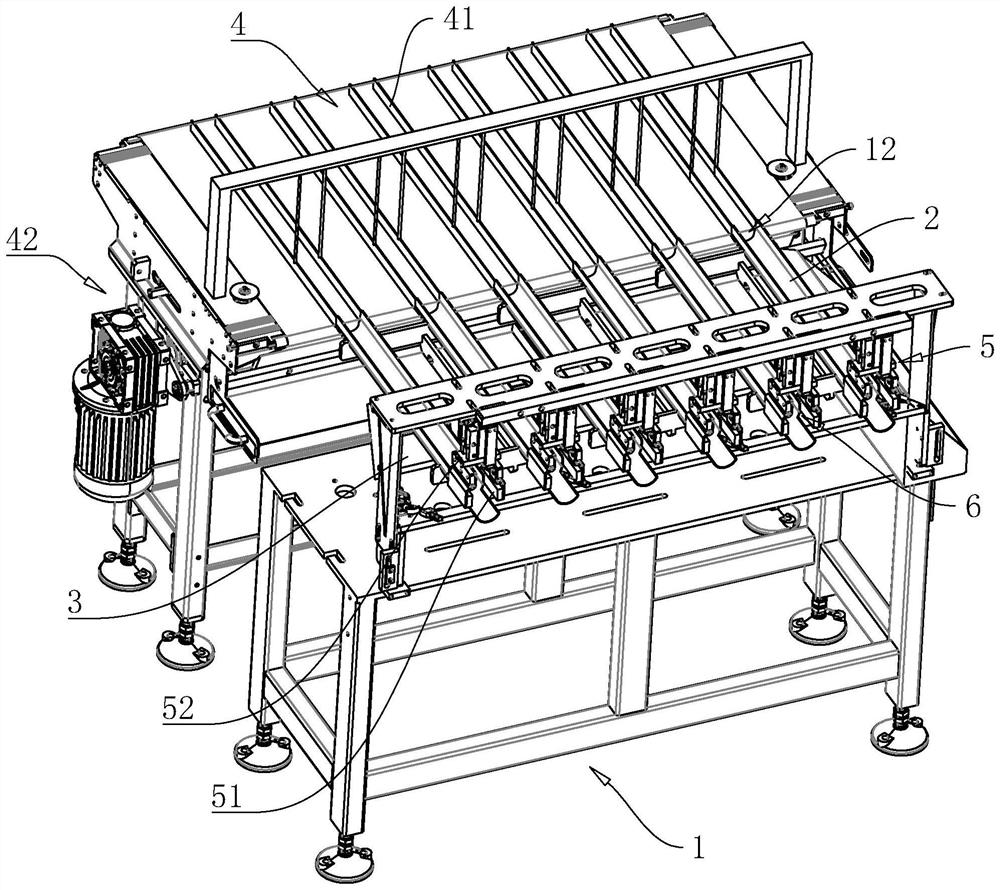

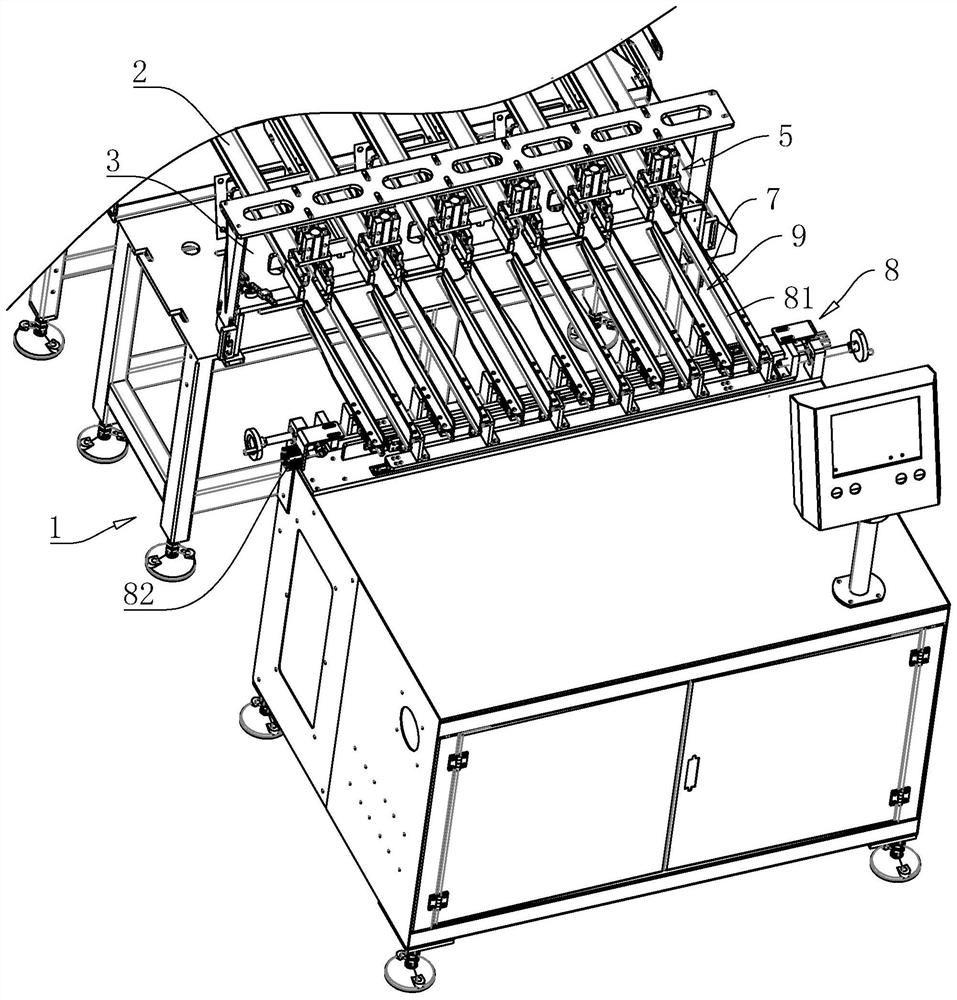

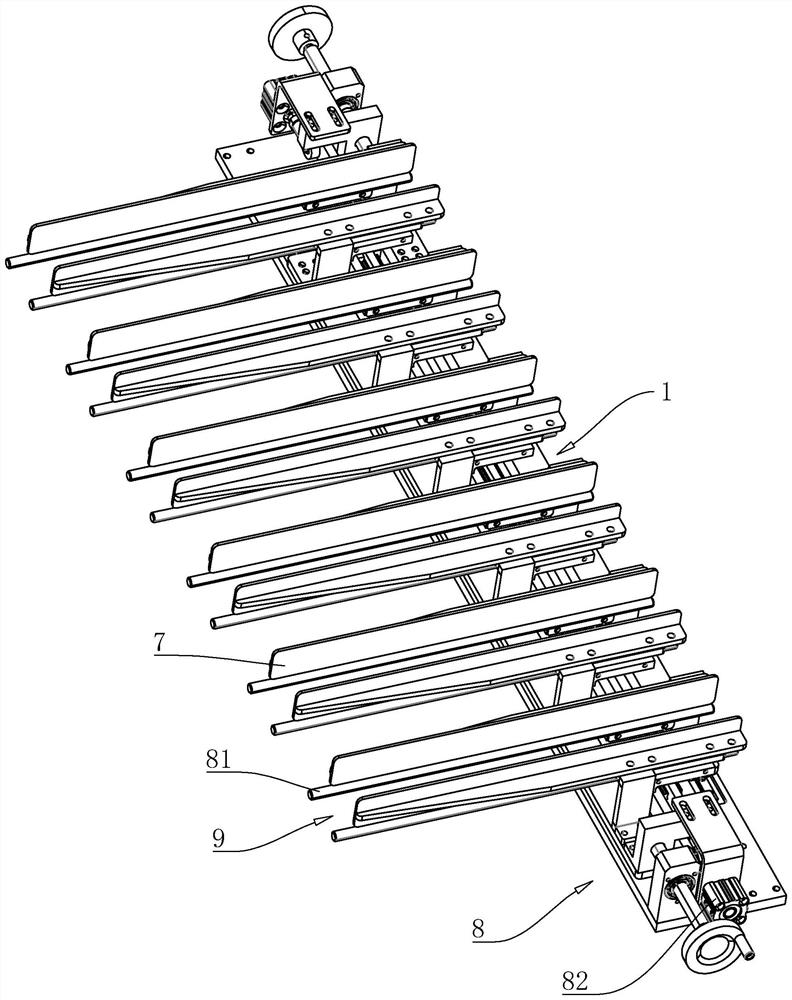

Blocky material conveying device and food loading production line

A block material and conveying device technology, applied in the direction of conveyors, vibrating conveyors, conveyor objects, etc., can solve the problem of the overturning or dumping of block materials, the large friction between the belt surface and the material, and the inability to control the feeding more accurately. Quantity and other issues to achieve the effect of controlling the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Exemplary embodiments of the present application are described below with reference to the accompanying drawings, which include various details of the embodiments of the present application to facilitate understanding, and should be considered as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the present application. Also, descriptions of well-known functions and constructions are omitted from the following description for clarity and conciseness.

[0053] It should be noted that the terms "first", "second" and the like in the present invention are used to distinguish similar objects, and are not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used may be interchanged under appropriate circumstances such that the embodiments of the disclosure described h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com