Key stripping feeding mechanism and working method thereof

A technology of feeding mechanism and ejecting mechanism, which is applied in labeling machines, packaging, printed circuits, etc., can solve problems such as low equipment efficiency, large product loss, and serious displacement, so as to reduce the ratio of throwing materials and improve production Efficiency, the effect of reducing the probability of drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments.

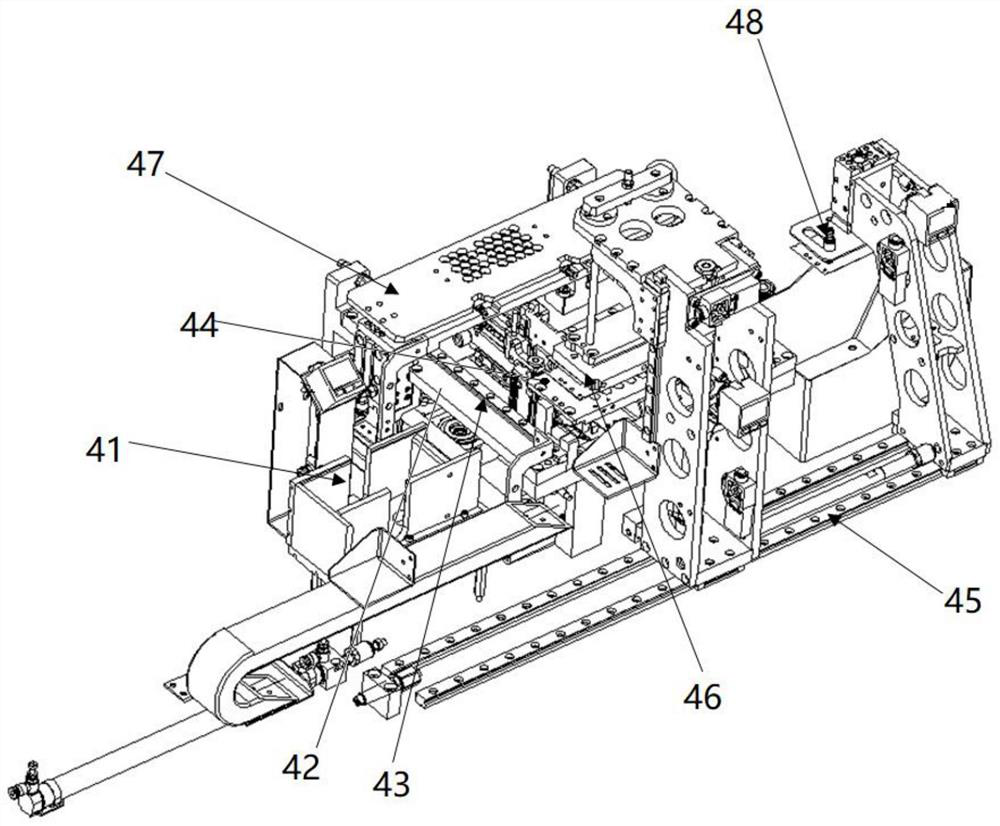

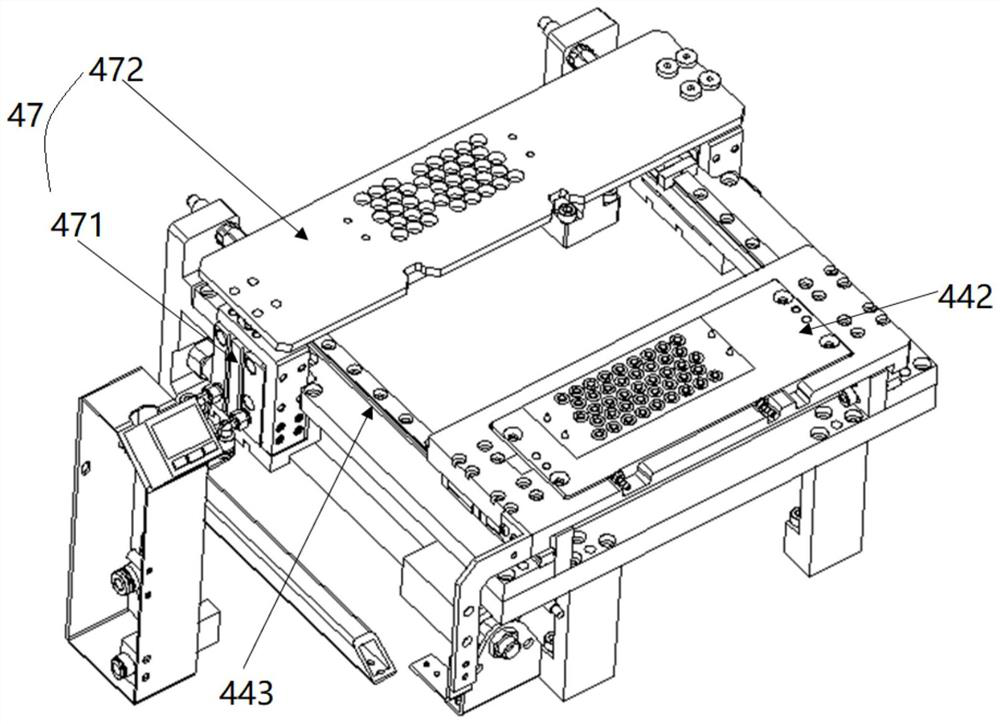

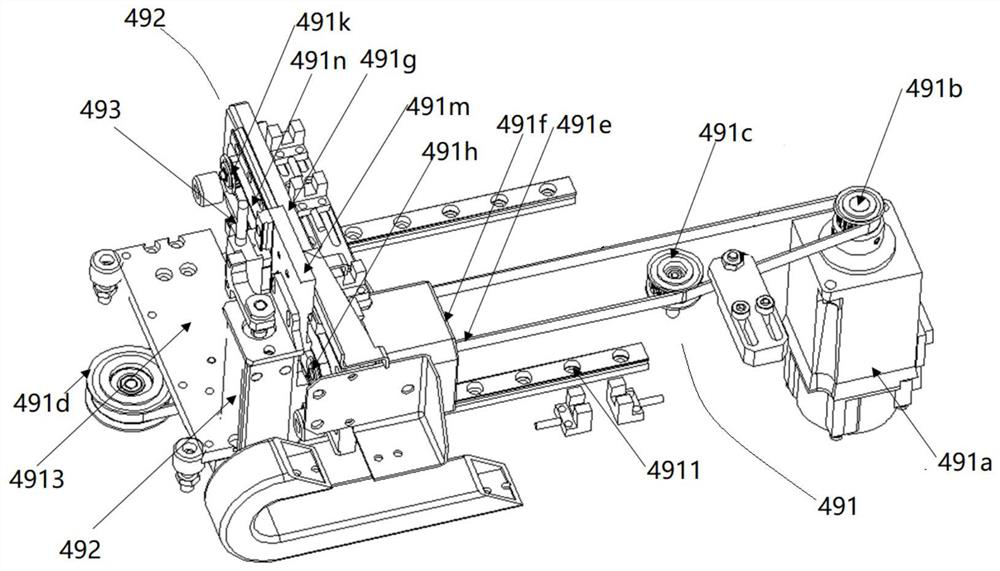

[0034] like Figure 1-3 The shown key peeling feeding mechanism includes a silo 41, a peeling platform 42, a translation linear guide 43, a front and rear translation device 44, a translation linear guide 2 45, a transfer and suction device 46, a platen device 47, and a release film. The suction device 48 and the ejecting mechanism 49, the bin 41 is arranged on the left side of the peeling platform 42, the translation linear guide rail 1 43 is arranged on the peeling platform 42, and the front and rear translation devices 44 are arranged above the translation linear guide rail 1 43, The second translation linear guide rail 45 is arranged on the front side of the peeling platform 42, the transfer suction device 46 and the release film suction device 48 are arranged on the second translation guide rail 45, the pressing plate device 47 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com