Thermoelectric chemical oxidation treatment device with hemispherical cover body

A thermoelectrochemical and oxidation treatment technology, which is applied in anodic oxidation, electrolytic components, electrolytic process, etc., can solve problems affecting processing efficiency and achieve the effect of improving uniformity and flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

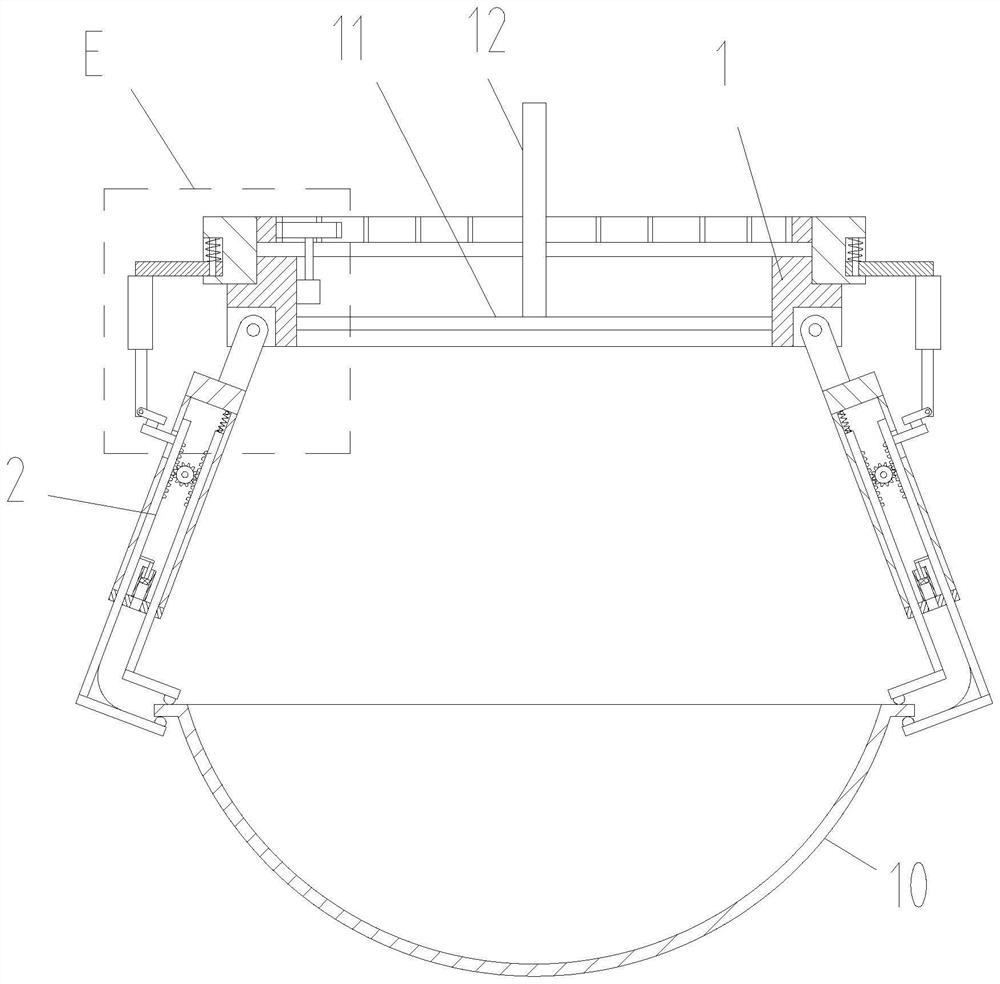

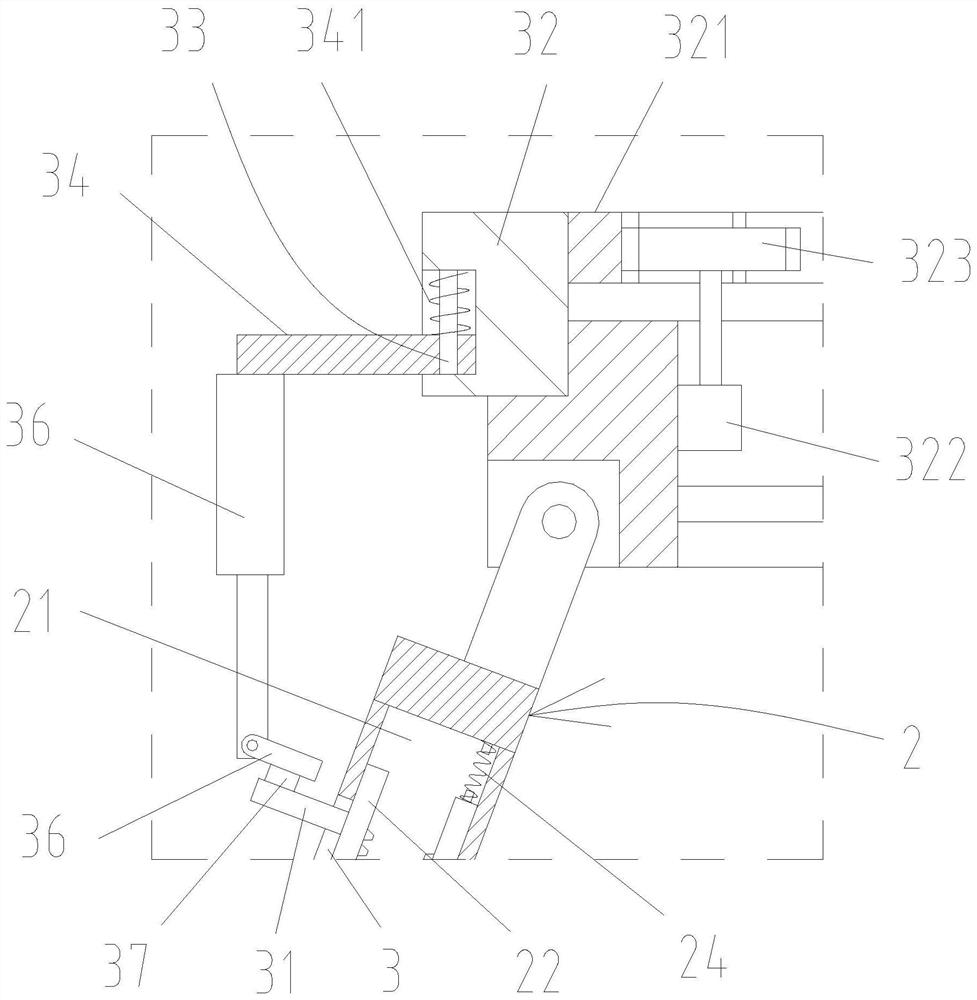

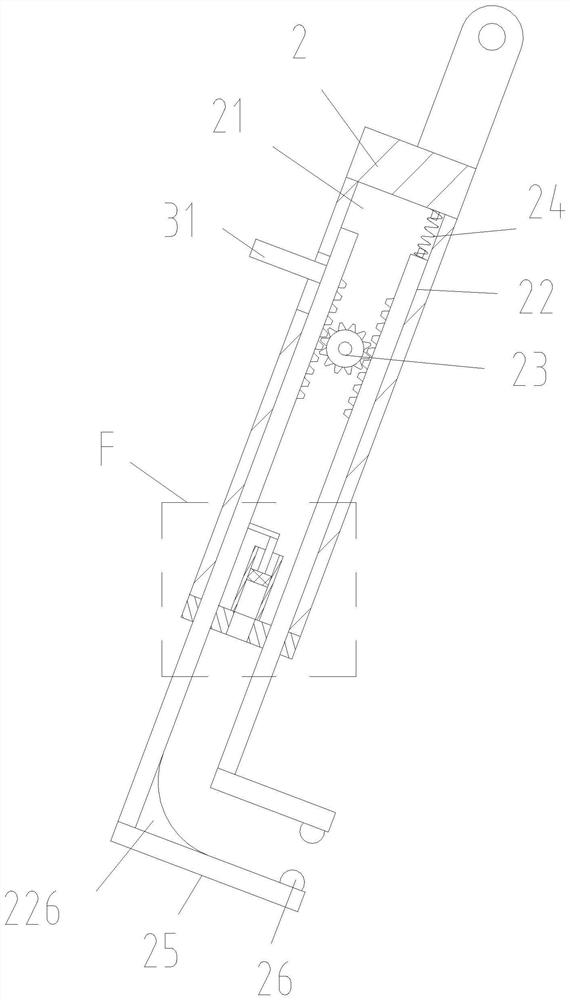

[0022] like Figure 1-4 As shown, the thermo-electrochemical oxidation treatment device for a hemispherical cover provided by the present invention includes a suspension ring 1, the inner side of the suspension ring 1 is fixedly connected to a support rod 11, the upper middle of the support rod 11 is fixedly connected to a suspension rod 12, and the suspension rod 12 is rotated through a pin shaft On the existing hoist, at least four clamping rods 2 are set at the bottom of the lifting ring 1, a rotating groove is set at the bottom of the lifting ring 1, the clamping rod 2 is rotatably connected with the rotating groove and a torsion spring is set, and the clamping rod 2 is based on the axis of the lifting ring 1. Circular array, a cavity 21 is arranged inside the clamping rod 2, the cavity 21 is symmetrically slidingly connected to two sliding rods 22, the cavity 21 is rotatably connected to the reversing gear 23, and the opposite sides of the two sliding rods 22 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com