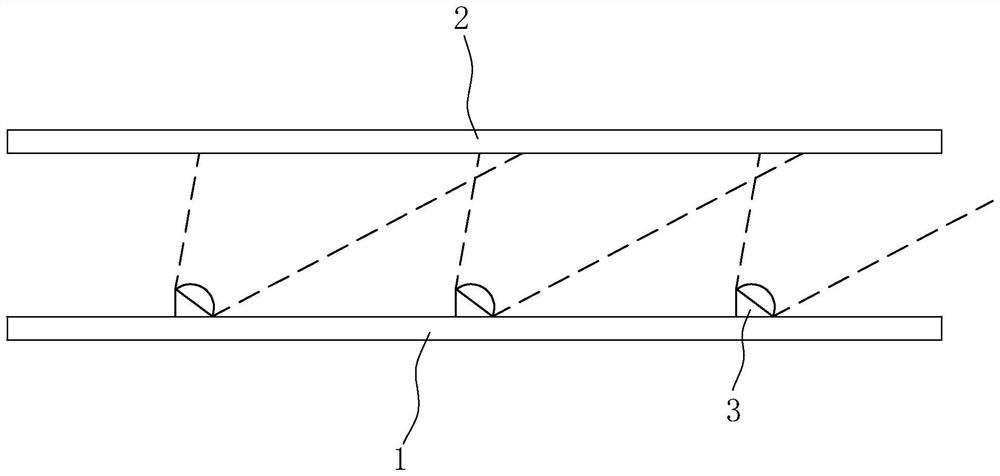

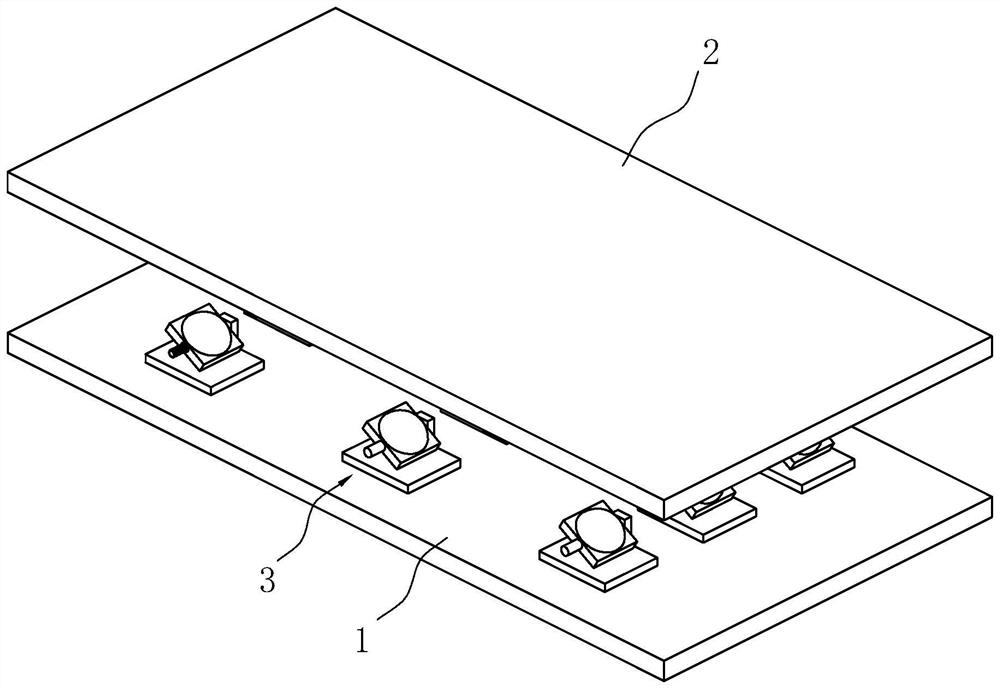

Backlight module and method for reducing thickness of backlight module

A backlight module and light source technology, which is applied to the semiconductor devices of light-emitting elements, light sources, optics, etc., can solve the problems of dark areas in the backlight module, increase in the thickness of the backlight module, etc., and achieve the goal of reducing the thickness and expanding the illuminated area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

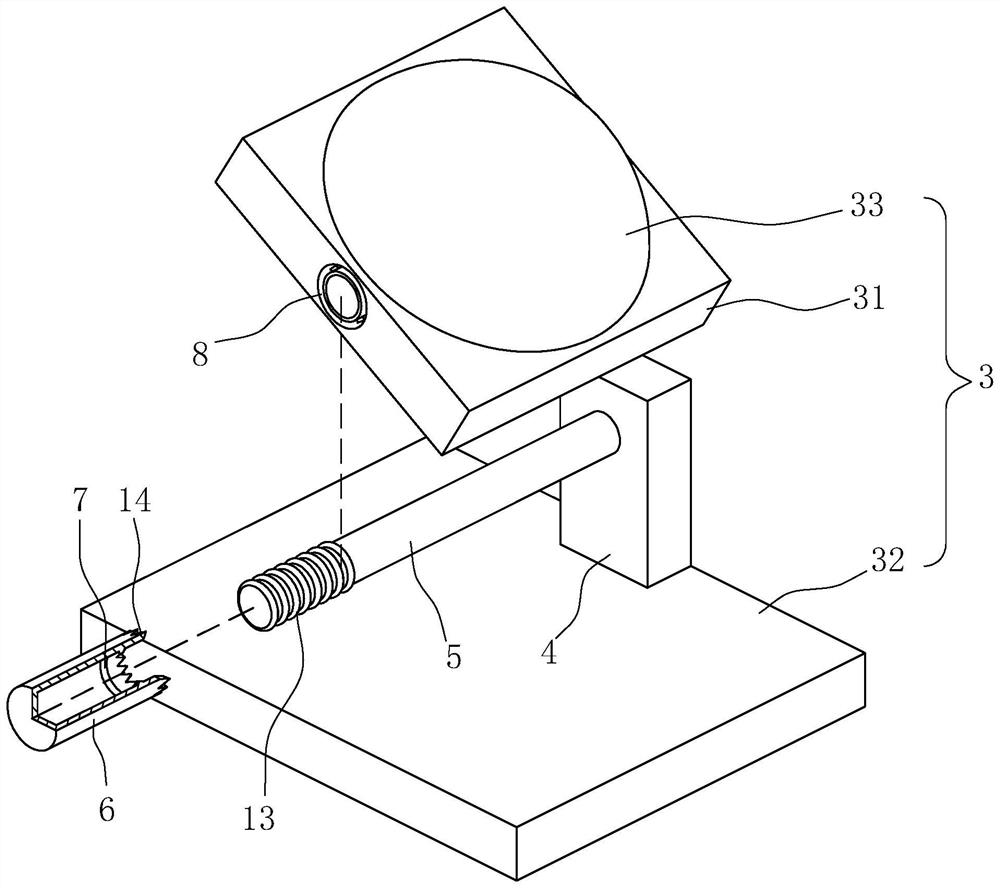

[0043] refer to figure 2 and image 3 , the difference between Embodiment 2 and Embodiment 1 is that: the lamp bead 3 includes a base 32, a light source 31 and a lens 33, the base 32 is arranged on the mounting plate 1, and one end of the top surface of the base 32 is fixed with a fixing block 4. A connecting shaft 5 is fixed on the side wall, the housing of the light source 31 is arranged on the connecting shaft 5 , the light source 31 can rotate around the connecting shaft 5 , and the lens 33 is fixed on the housing of the light source 31 . The end of the connecting shaft 5 away from the fixing block 4 is provided with a limiting member for limiting the rotation of the lamp beads 3 . The light source 31 rotates on the connecting shaft 5, which is convenient to adjust the direction of the light, and it is convenient to adjust the direction of the light according to different design requirements.

[0044] refer to figure 2 and image 3 In this embodiment, the limiting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com