LED flat light source structure

A planar light source and curved surface technology, applied in the field of LED planar light source structure, can solve the problems of increased difficulty in optical design, inconspicuous effect, and low light utilization rate of light source, etc., to achieve glare reduction effect, convenient expansion, and high light energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

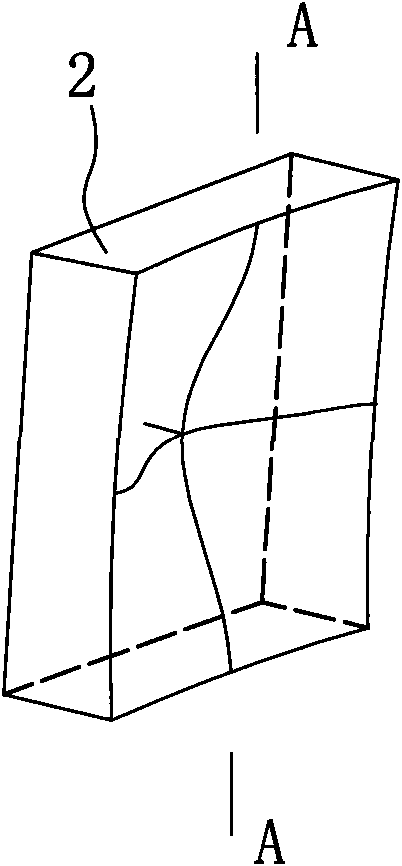

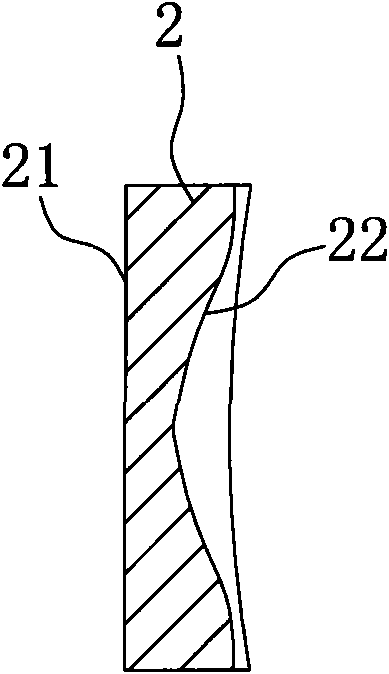

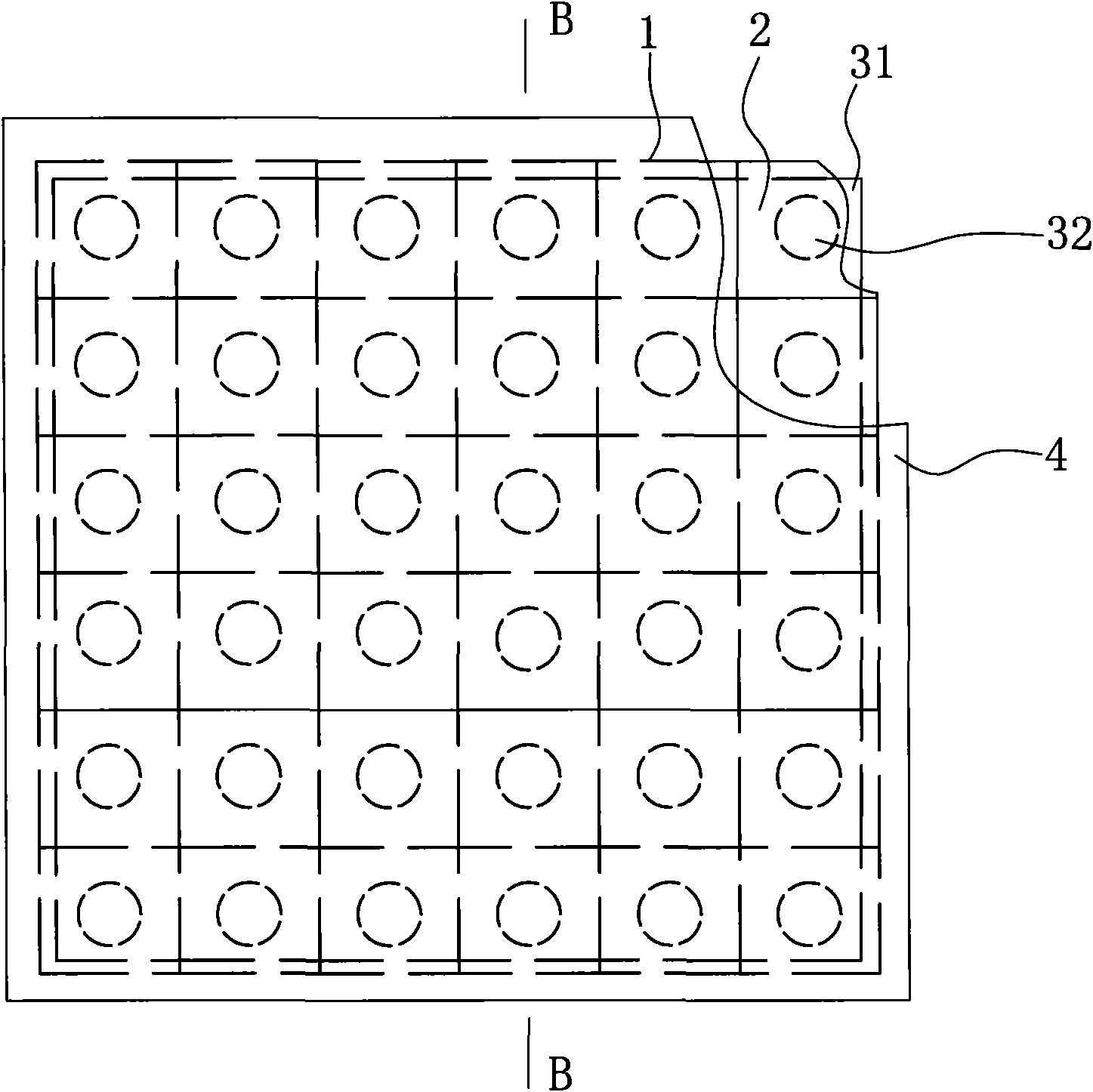

[0025] Such as figure 2 , figure 2 The LED planar light source structure of Embodiment 1 of the present invention shown in (a) includes an aluminum substrate 3, on which several LED light-emitting diodes are installed as illuminants 32, and the front of the several illuminants 32 is provided with a The light guide plate 1 is provided with a diffuse transmission plate 4 in front of the light guide plate 1 to further soften the light, so that the light distribution close to the same illuminance becomes the light distribution close to the same brightness, so as to improve the visual comfort. Such as figure 1 , figure 1 As shown in (a), the light guide plate 1 is composed of several square light guide plate units 2 with free-form surfaces 22 arranged in warp and weft into an integrated structure, which is simple in structure and easy to manufacture. The lower end surface of the light guide plate unit 2 is a light-emitting surface 21, and the other side of the light guide plat...

Embodiment 2

[0027] Such as Figure 4 , Figure 4 (a) shows the LED planar light source structure of Embodiment 2 of the present invention. This structure is roughly the same as Embodiment 1. The difference is that the light guide plate unit 2 of the LED planar light source structure is a regular hexagon, and the light guide plate 1 is made of The regular hexagonal light guide plate units 2 are staggered in a honeycomb form to form an integrated structure, which has a compact structure and a beautiful appearance.

[0028] The above-mentioned two embodiments are only preferred structures of the present invention, and these two structures can achieve better illumination effects. The light source of the LED forms a circular light spot with a radius of 3 meters through the light guide plate unit 2, and because the indoor illuminance needs to take into account the visual Comfortable, the light-emitting surface 21 of the light guide plate unit 2 is frosted, so that the human eye can see that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com