Working method of differential driving unit for heavy-load AGV

A technology of differential drive and working method, which is applied in electric vehicles, non-rotational vibration suppression, power management, etc. It can solve the problems of not including the guiding function, not being able to bear the lateral force of the road surface, not having the function of shock absorption, etc., and achieving the goal of transmission precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention; obviously, the described embodiments are only a part of the embodiments of the present invention; rather than all the embodiments. Based on the embodiments of the present invention; all other embodiments obtained by those of ordinary skill in the art without creative work; all belong to the protection scope of the present invention.

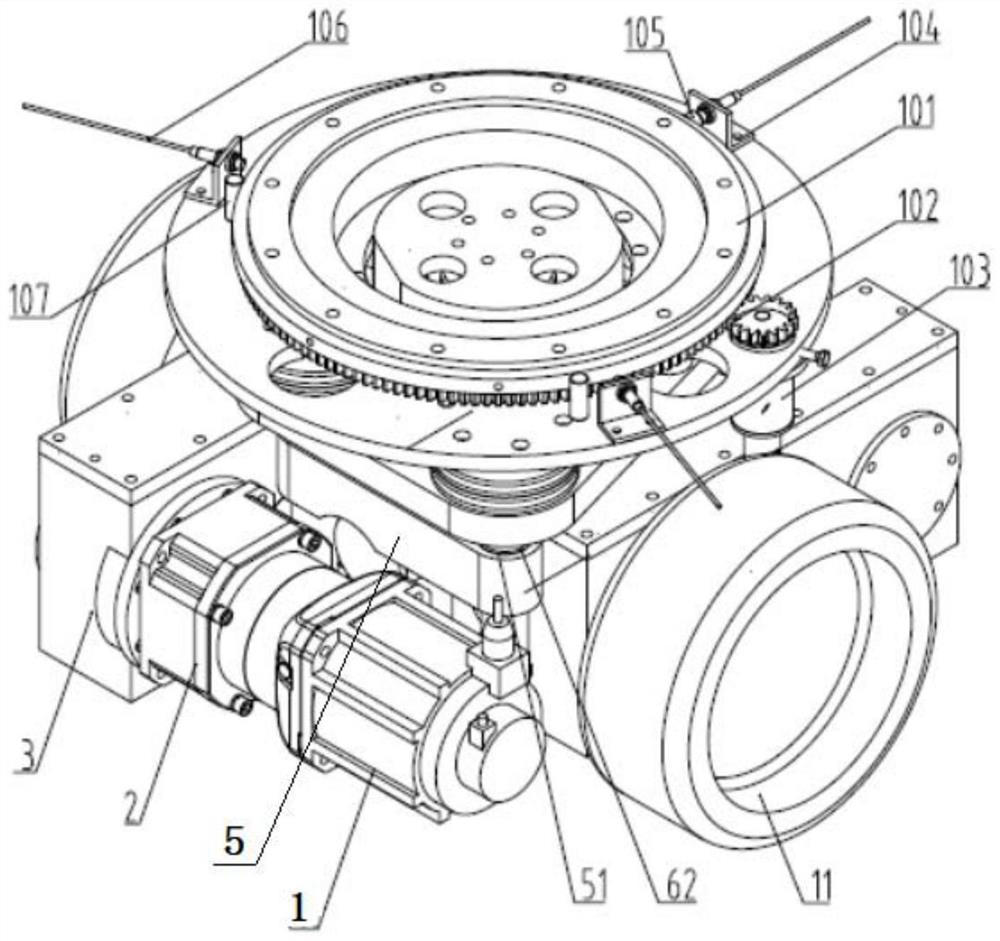

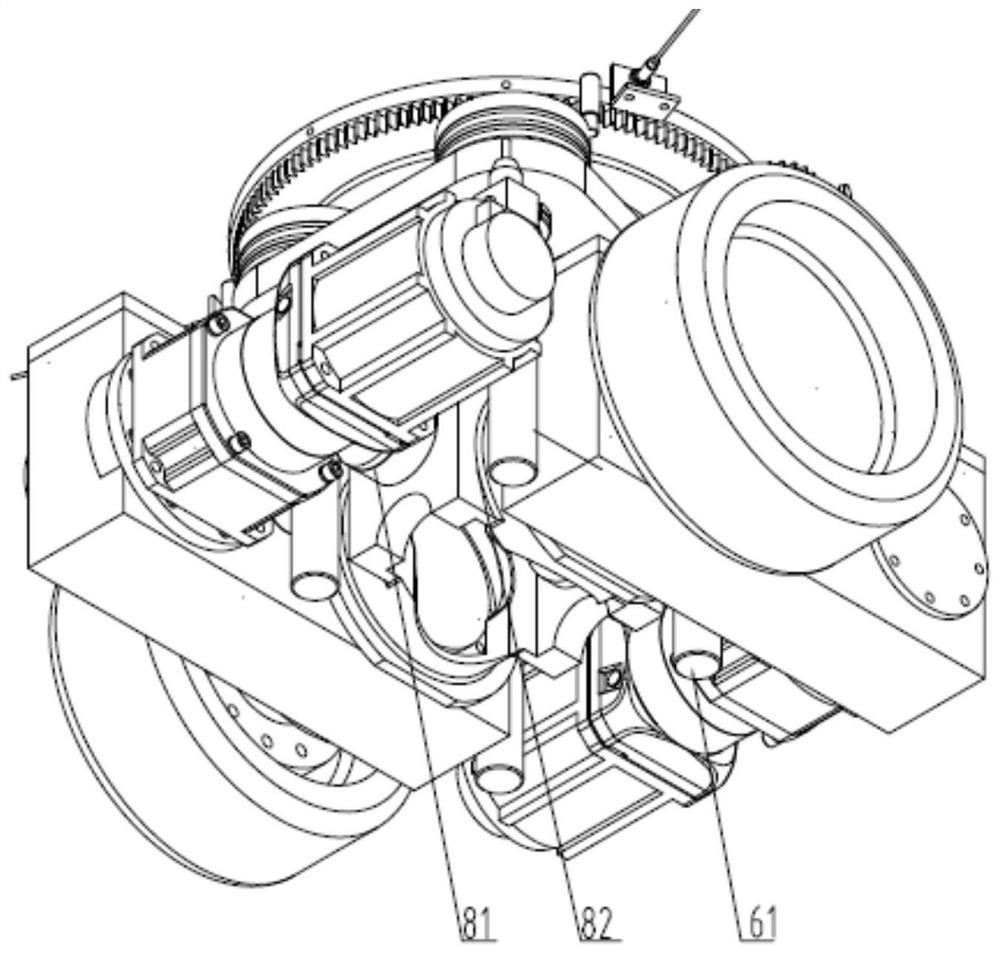

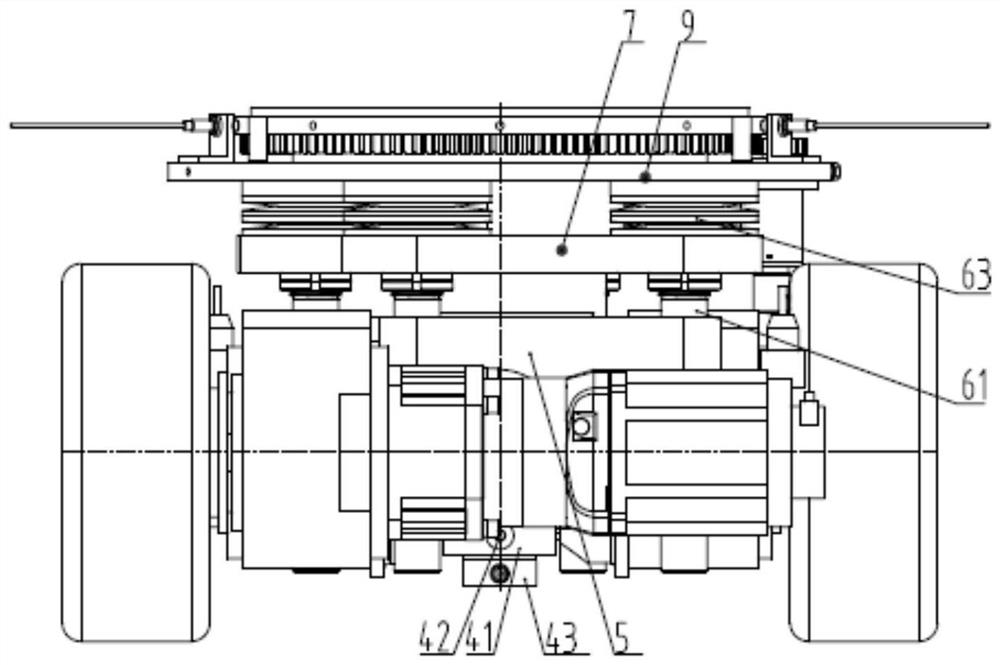

[0049] like Figure 1-7 As shown, the present invention provides a working method of a differential drive unit for a heavy-duty AGV. The differential drive unit includes a transmission system, a lifting mechanism 4, a lower wheel frame 5, a guide damping mechanism 6, an upper wheel Rack 7, swing mechanism 8, tray 9 and slewing mechanism 10;

[0050] The transmission system is two sets, and the center is symmetrically arranged. Each set of systems incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com