Waterproof structure of motor rotating shaft

A waterproof structure and motor shaft technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of fast consumption, increased friction of the shaft, and reduced sealing and waterproof effects, so as to reduce the cost of use, improve the sealing effect, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

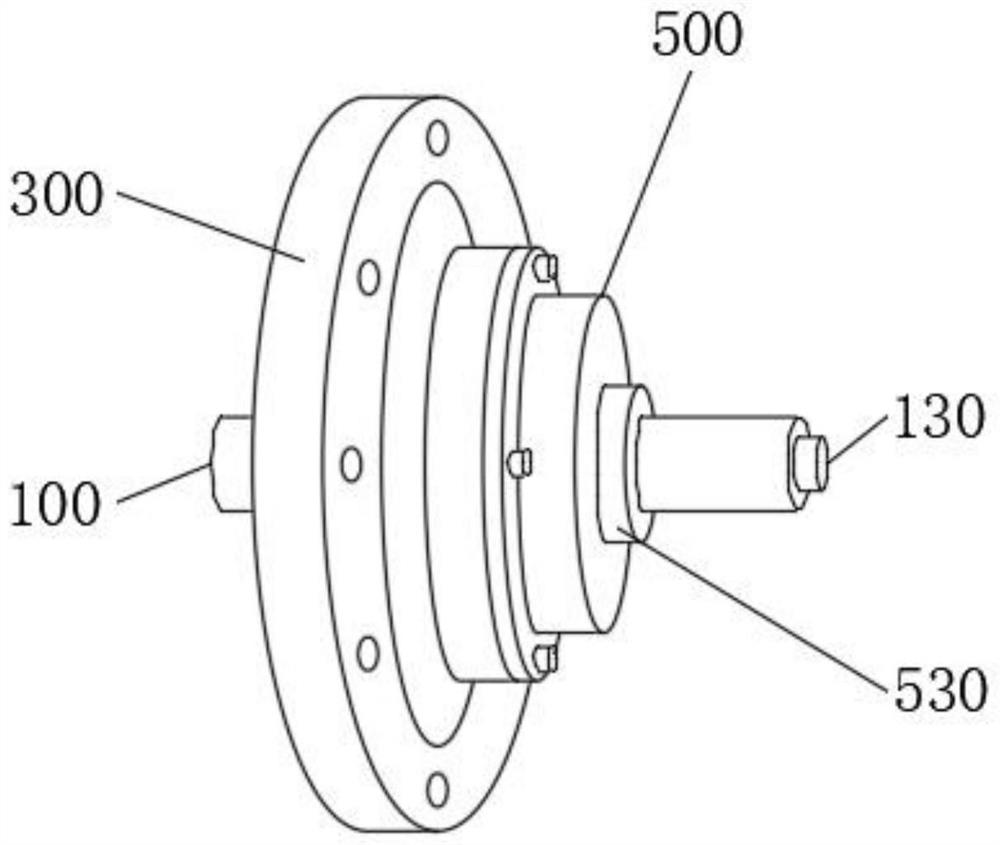

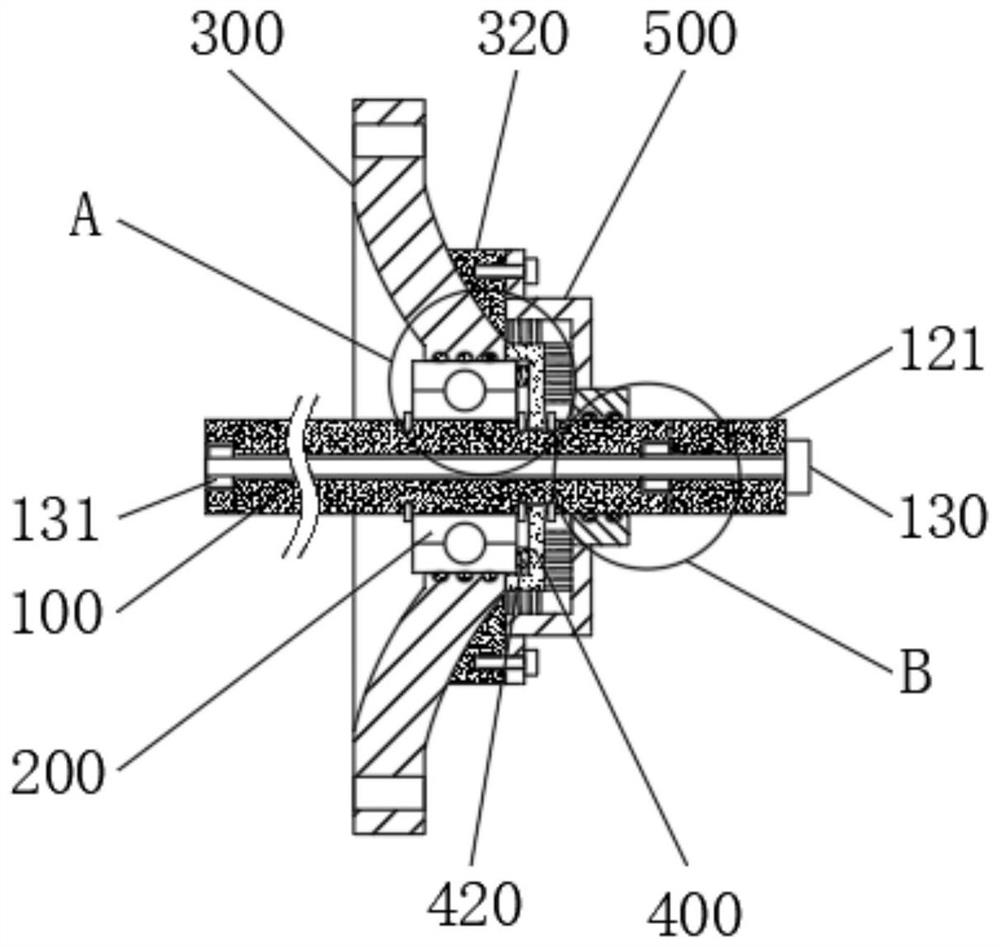

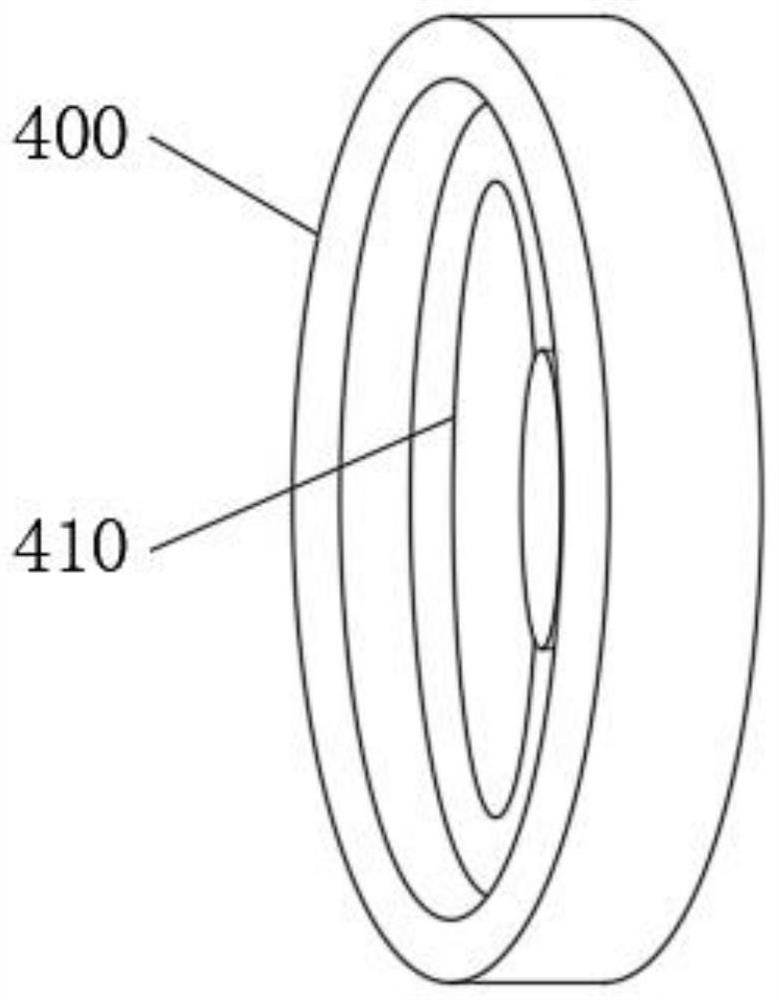

[0026] see figure 2 and Image 6 , the present invention provides a technical solution: a waterproof structure for a motor shaft, including a shaft body 100, a waterproof bearing 200, a motor end cover 300, an oil seal 400 and a sealing cover 500, and the waterproof bearing 200 is sleeved on the outer side wall of the shaft body 100. , the motor end cover 300 is sleeved on the outer side wall of the waterproof bearing 200 , the oil seal 400 is clamped on the outer side wall of the rotating shaft body 100 and is located on the right side of the waterproof bearing 200 , and the sealing cover 500 is sleeved on the right side of the outer side wall of the rotating shaft body 100 , and is located on the right side of the oil seal 400, the right end of the shaft body 100 is provided with a card slot 110, the inner cavity of the card slot 110 is clipped with a card block 120, and the right end of the card block 120 is integrally formed with a connecting shaft 121, the card groove 11...

Embodiment 2

[0028] see figure 2 , image 3 and Figure 5 , the present invention provides a technical solution: a waterproof structure for a motor shaft, including a shaft body 100, a waterproof bearing 200, a motor end cover 300, an oil seal 400 and a sealing cover 500, and the waterproof bearing 200 is sleeved on the outer side wall of the shaft body 100. , the motor end cover 300 is sleeved on the outer side wall of the waterproof bearing 200 , the oil seal 400 is clamped on the outer side wall of the rotating shaft body 100 and is located on the right side of the waterproof bearing 200 , and the sealing cover 500 is sleeved on the right side of the outer side wall of the rotating shaft body 100 , and is located on the right side of the oil seal 400. The inner side wall of the motor end cover 300 is provided with a first installation groove 310, which is arranged in order from left to right. The inner cavity of the first installation groove 310 is clamped with a first sealing ring 31...

Embodiment 3

[0030] see Figure 4-6, the present invention provides a technical solution: a waterproof structure for a motor shaft, including a shaft body 100, a waterproof bearing 200, a motor end cover 300, an oil seal 400 and a sealing cover 500, and the waterproof bearing 200 is sleeved on the outer side wall of the shaft body 100. , the motor end cover 300 is sleeved on the outer side wall of the waterproof bearing 200 , the oil seal 400 is clamped on the outer side wall of the rotating shaft body 100 and is located on the right side of the waterproof bearing 200 , and the sealing cover 500 is sleeved on the right side of the outer side wall of the rotating shaft body 100 , and is located on the right side of the oil seal 400, the inner side wall of the sealing cover 500 is fixedly connected with the first oil storage ring 510 on the left side, and is arranged in order from left to right, and the inner side of the right side wall of the sealing cover 500 is fixedly connected with a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com