Improvements relating to transportation of wind turbine rotor shaft hub

A technology for wind turbines and rotor shafts, which is applied to the transportation of wind turbines, wind turbines in the same direction as the wind, wind turbines, etc., which can solve the problems of restrictions, large rotor hubs violating transportation restrictions, etc., and achieve the effect of reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

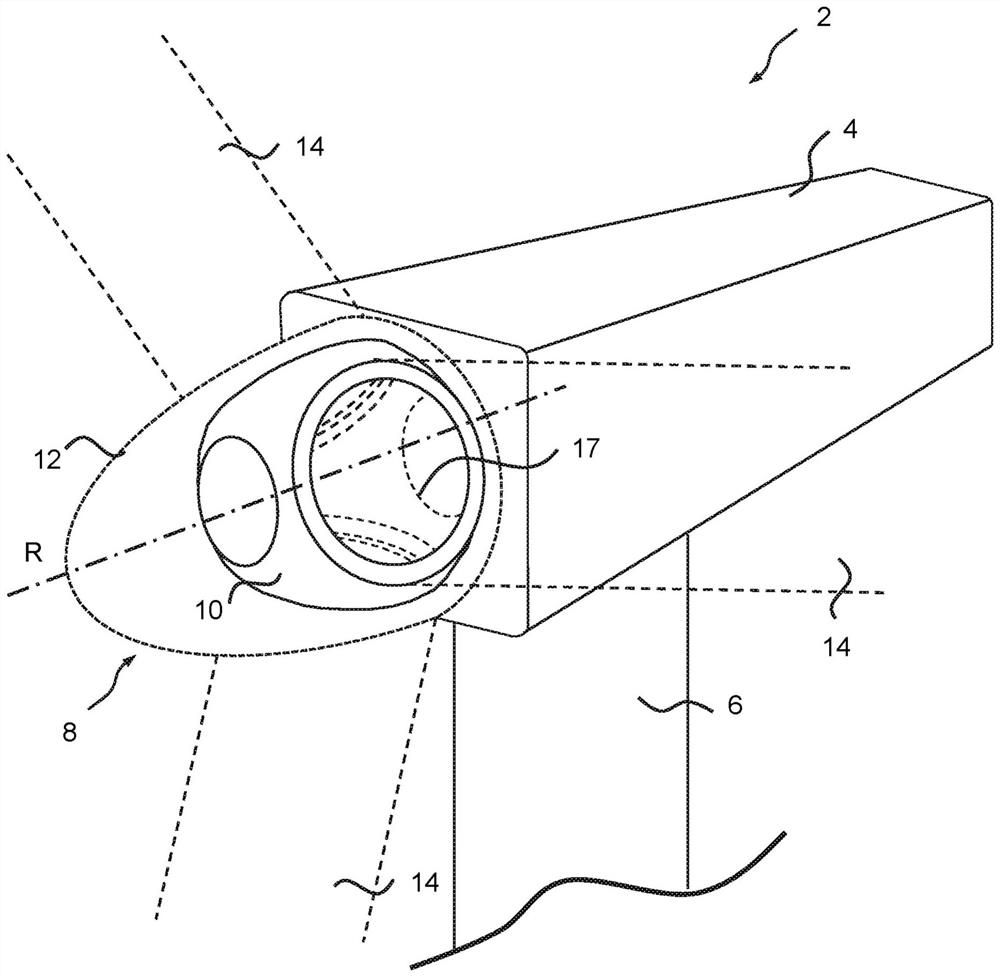

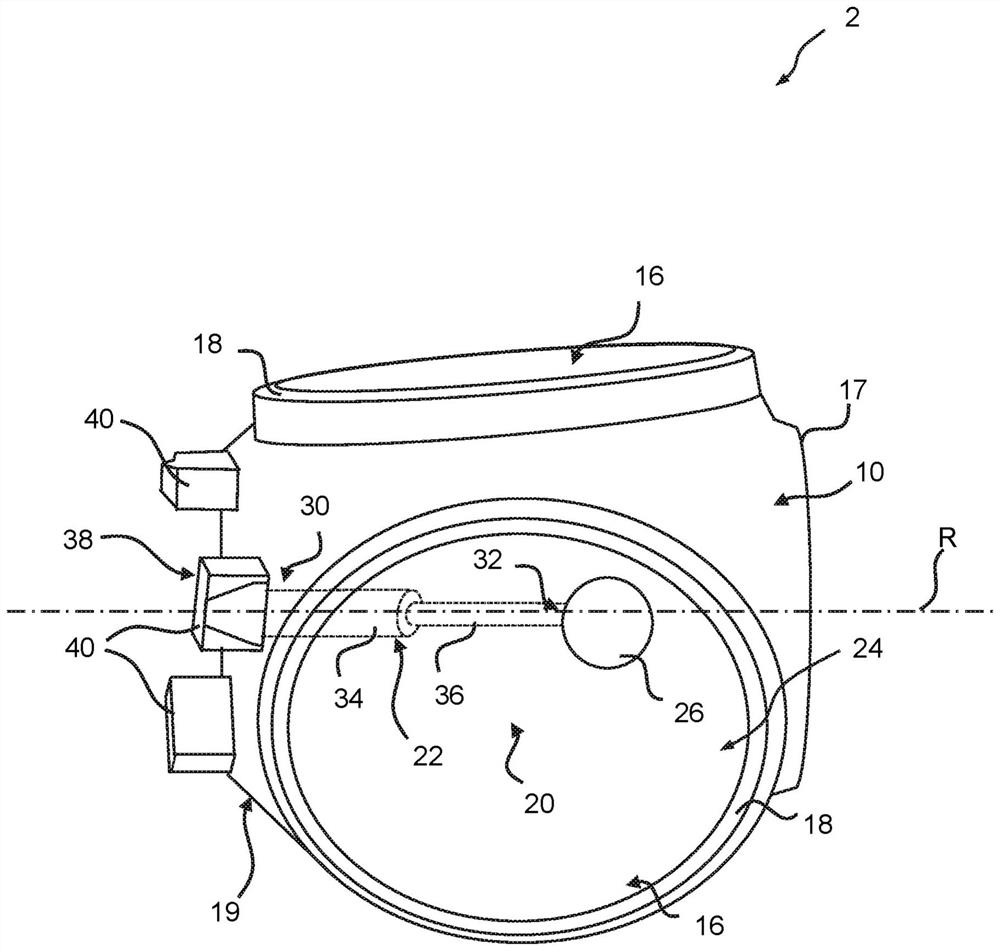

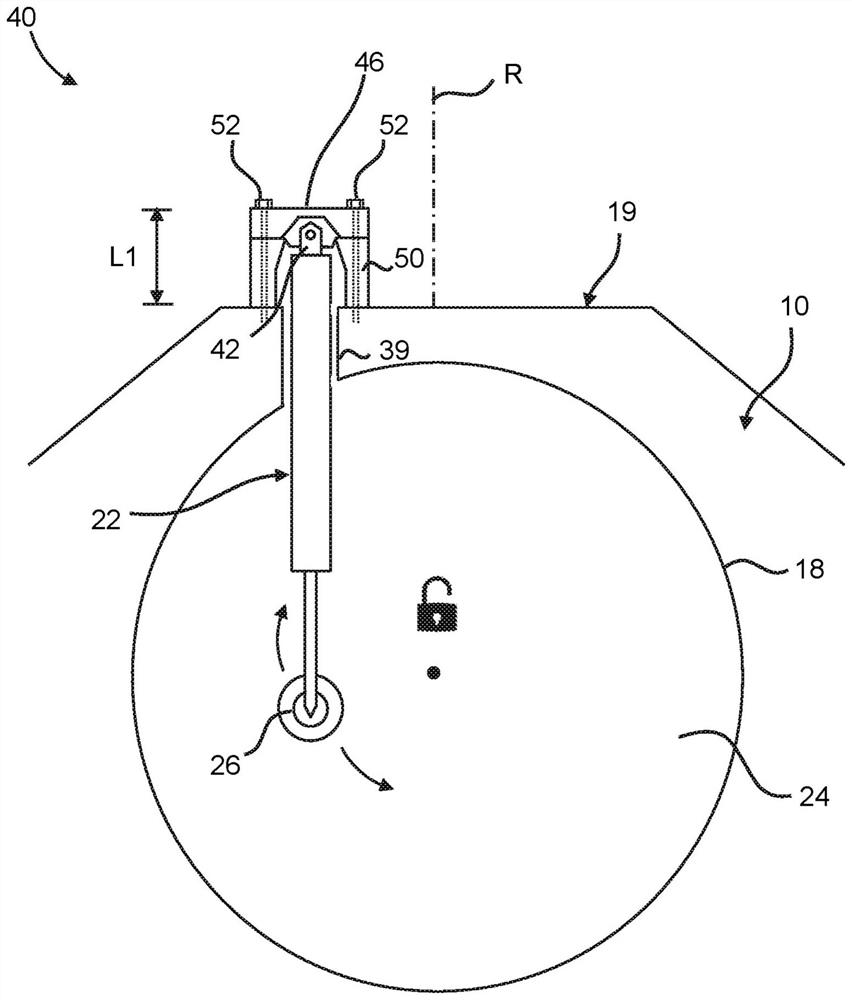

[0021] As described above, the present invention relates to solutions and methods for configuring a wind turbine hub for transportation such that the dimensional envelope of the hub is reduced along at least one axis. In the known art, the outer dimensions of the hub are fixed during manufacture. In order to be transported to where the hub is to be installed, the hub must be loaded onto a trailer and transported by road for at least a certain distance. Public roads often have width restrictions to ensure the safety of other road users, and height restrictions to ensure that loads are not compromised by low bridges, gantry and other intersecting road structures along the route. For this reason, therefore, these width and height constraints are design and engineering constraints for wind turbine hubs. Accordingly, the present invention provides a device by which the outer dimensions of the hub can be reduced prior to transport, after which the hub can be reconfigured to its in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com