Eccentric wheel offset reinforcing bar connector

A technology of steel bar connector and eccentric wheel, applied in structural elements, building components, building reinforcements, etc., can solve the problems of narrow application range, difficult quality control, strong construction concealment, etc., to speed up construction speed and suitable for occasions. Widespread, reduced material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

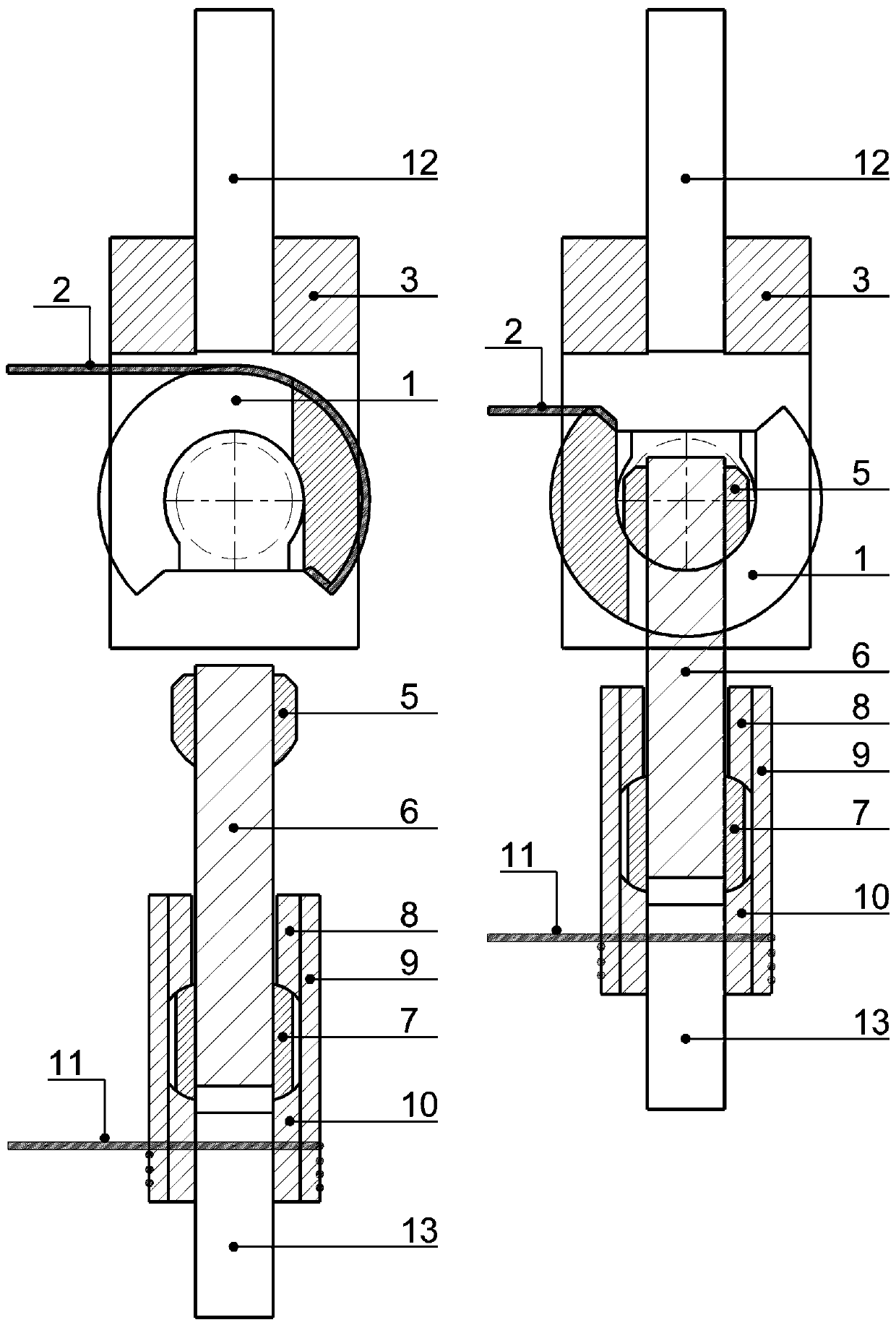

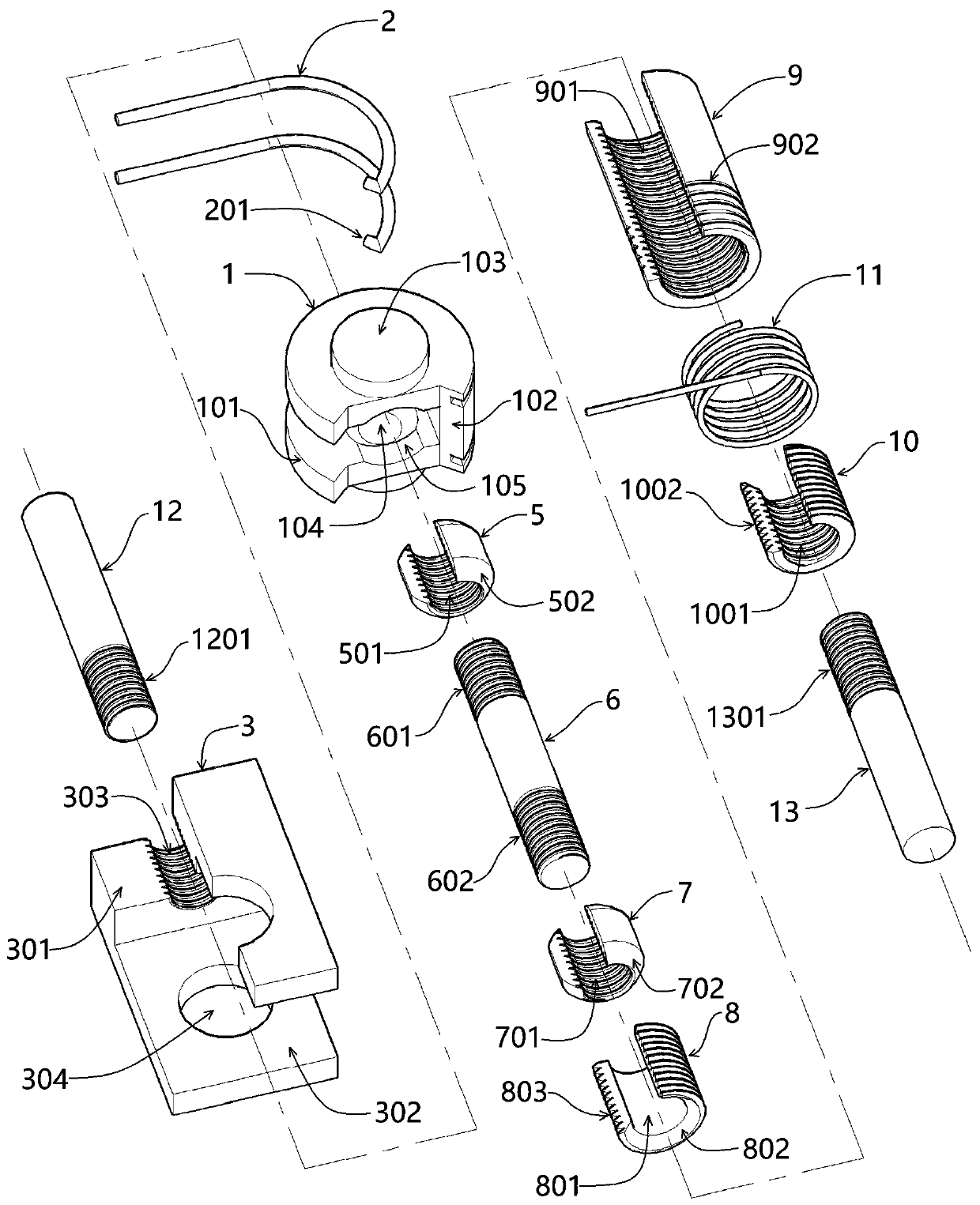

[0025] Such as Figure 1~Figure 4 Shown, a specific embodiment of the present invention, connecting steel bar one 12 and steel bar two 13, is characterized in that: comprise eccentric wheel 1, the first steel wire rope 2, opening connecting clip 3, the first nut 5, the intermediate connecting rod 6, the first Two nuts 7 , a first end anchor plate 8 , an anchor sleeve 9 , a second end anchor plate 10 and a second steel wire rope 11 .

[0026] The eccentric wheel 1 includes at least two side plates 101, a connecting plate 102, a connecting pin 103 and an anchoring groove 104. The anchoring groove 104 is arranged on the inner side of the side plate 101, and the side plate 101 is provided with a parallel notch 105 and a vertical notch 108, which are parallel to each other. The notch 105 is parallel to the plane where the side plate 101 is located, the vertical notch 108 is perpendicular to the plane where the side plate 101 is located, the size of the parallel notch 105 is larger ...

Embodiment 2

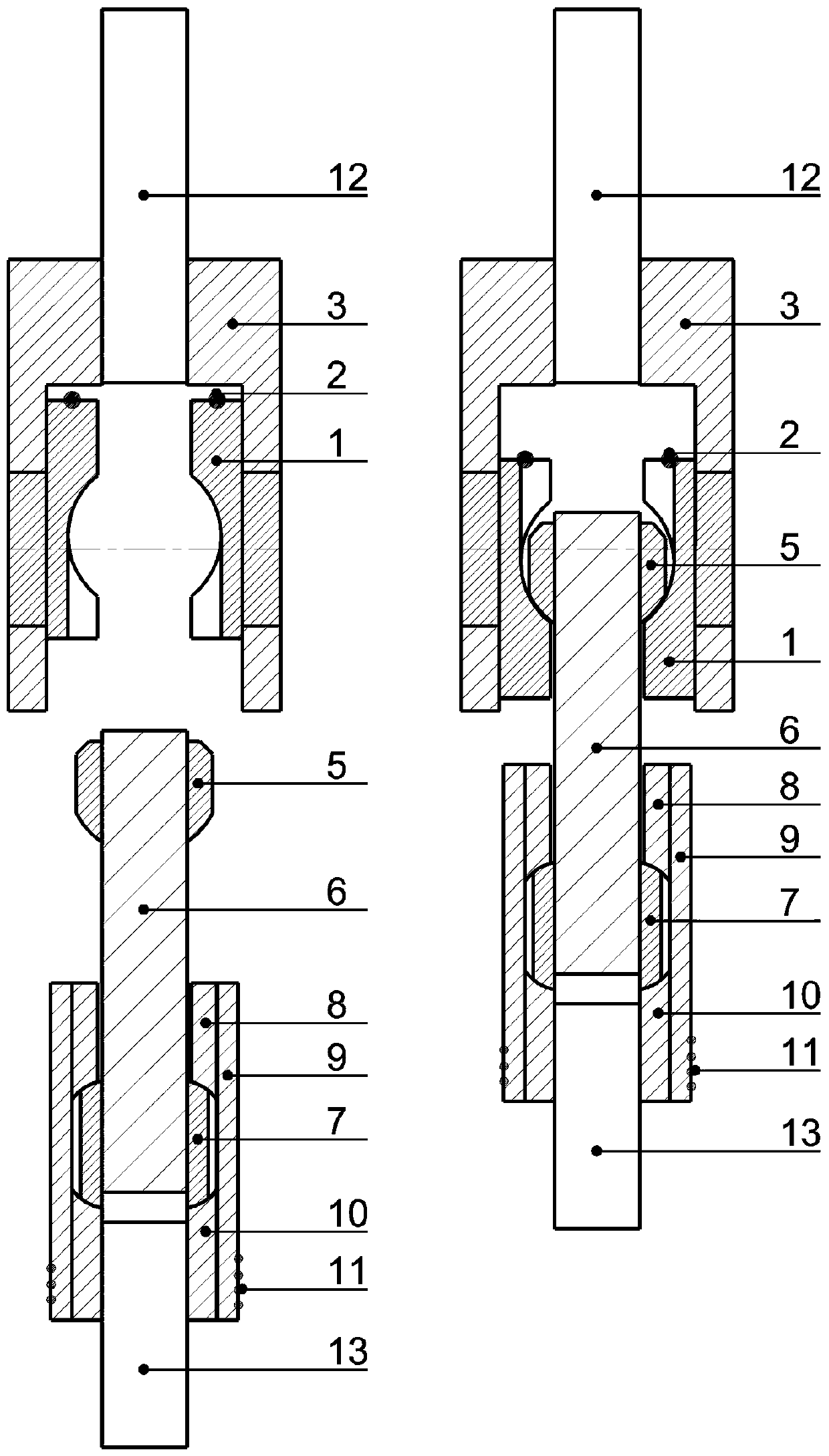

[0031] Such as Figure 5~Figure 7 Shown, a specific embodiment of the present invention, connecting steel bar one 12 and steel bar two 13, is characterized in that: comprise eccentric wheel 1, opening connecting clip 3, first nut 5, intermediate connecting rod 6, second nut 7, the first An anchor plate 8 at one end, an anchor sleeve 9 , an anchor plate 10 at a second end and a second wire rope 11 .

[0032] The eccentric wheel 1 includes two side plates 101, a connecting plate 102 and an anchoring groove 104, the anchoring groove 104 is arranged on the inner surface of the side plate 101, and the side plate 101 is provided with a parallel notch 105 and a vertical notch 108, and the parallel notch 105 and the side plate The plane where 101 is located is parallel, the vertical notch 108 is perpendicular to the plane where the side plate 101 is located, the size of the parallel notch 105 is larger than the first nut 5, and the first nut 5 is arranged in the anchoring groove 104; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com