Large plate glass curtain wall auxiliary installation equipment and installation technology thereof

A technology for installing equipment and glass curtain wall, applied in the direction of building, building structure, etc., can solve the problems of sling shaking of lifting equipment, electric suction cup and glass slipping, glass and building body collision, etc., to improve the use efficiency and reduce safety. Risks, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

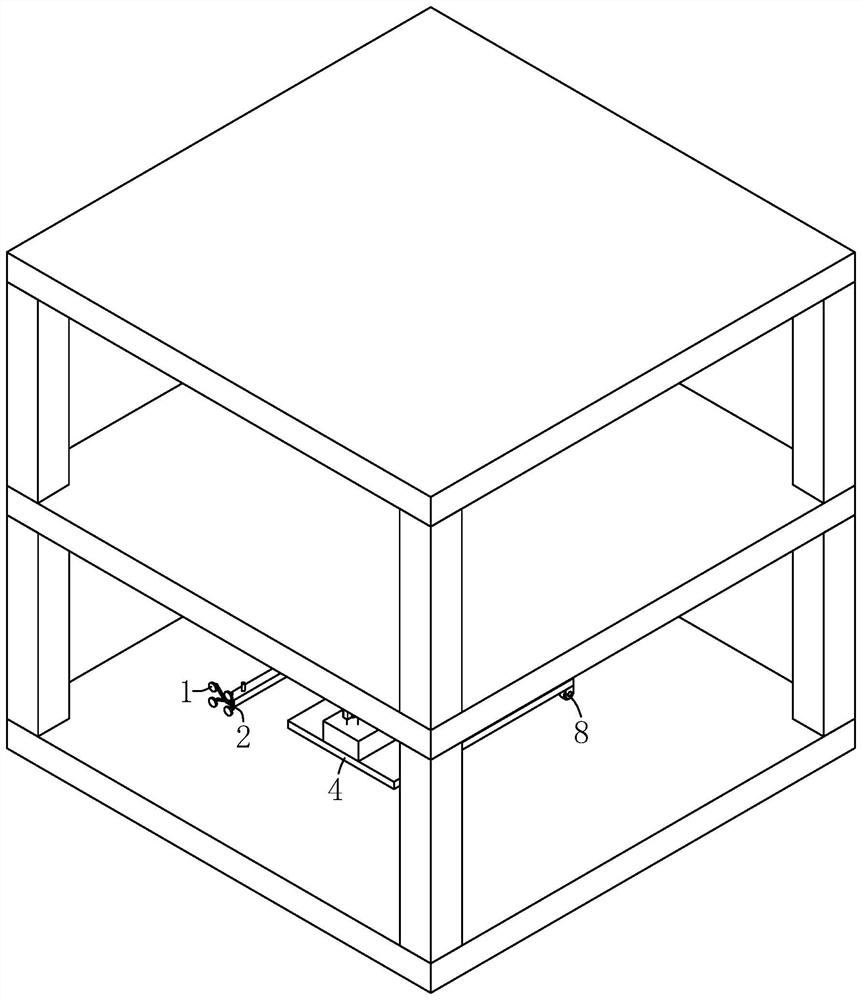

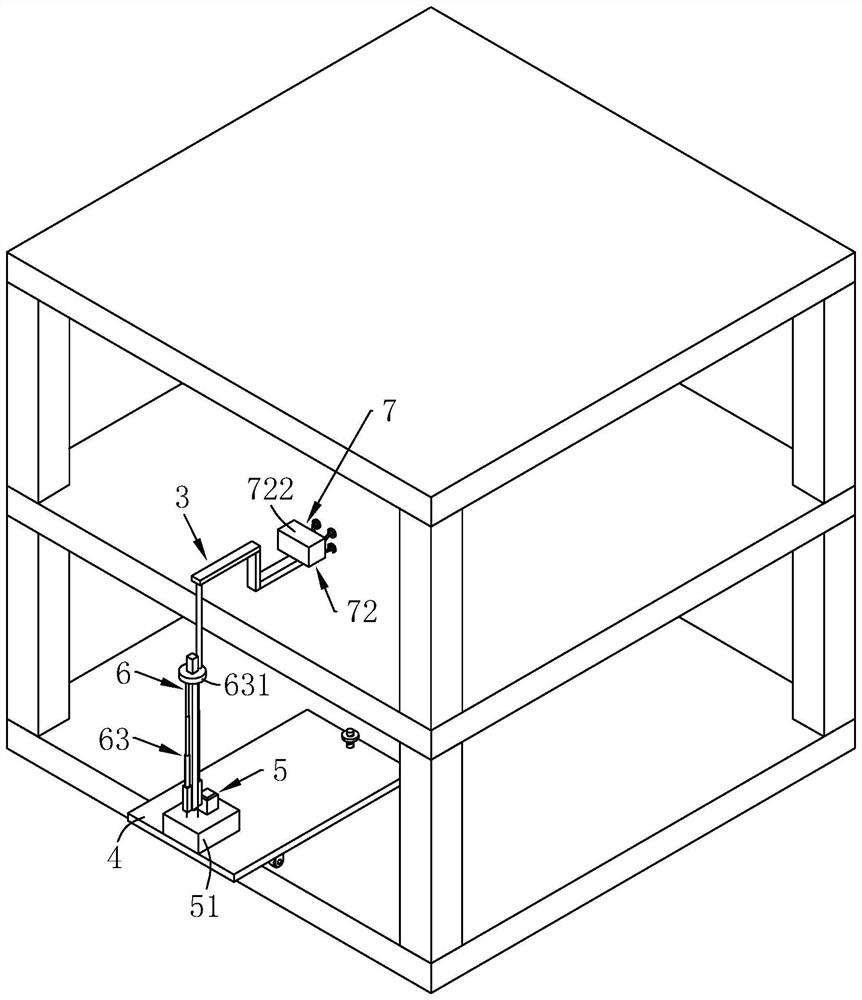

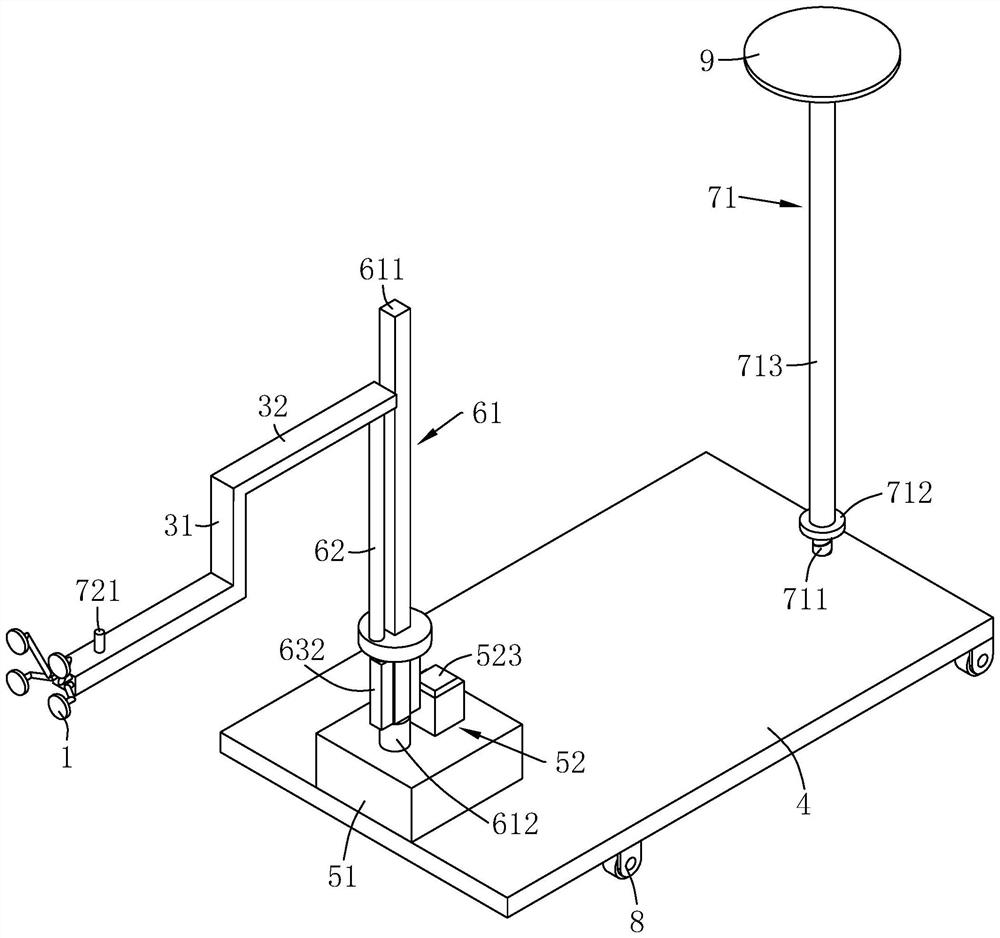

[0056] Attached to the following Figure 1-4 This application will be described in further detail.

[0057] In a first aspect, the embodiment of the present application discloses an auxiliary installation device for a large glass curtain wall.

[0058] The embodiment of the present application discloses an auxiliary installation device for a large glass curtain wall.

[0059] refer to figure 1 , figure 2 as well as image 3 , a large plate glass curtain wall auxiliary installation equipment includes a plurality of electric suction cups 1, a fixing frame 2 for fixing the plurality of electric suction cups 1, a landing gear 3, a base plate 4, a rotating mechanism 5, a lifting mechanism 6 and a base plate 4 for holding The counterweight mechanism 7 at the level of the plane; the plane where the base plate 4 is located is set horizontally. In order to facilitate the movement of the base plate 4 , four moving wheels 8 are bolted on the bottom wall of the base plate 4 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com