Real-time calibration device for rotation angle of cantilever of bucket wheel machine

A technology of rotation angle and calibration device, which is applied in angle/taper measurement, hydroelectric power generation, etc., can solve problems such as angle error, influence on material retrieving and transfer, difficult cantilever rotation angle deviation, etc., and achieve the effect of convenient and timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the contents of the description still belong to the patent of the present invention covered.

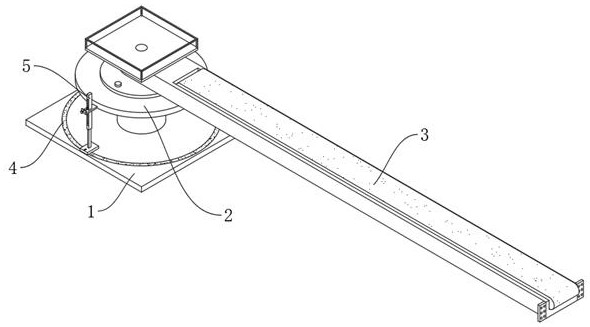

[0032] refer to figure 1 , a real-time calibration device for the rotation angle of a bucket wheel machine cantilever, comprising a bucket wheel machine mounting seat 1, a rotating seat 2 is installed on the bucket wheel machine mounting seat 1, a cantilever 3 is installed on the rotating seat 2, and the bucket wheel machine mounting seat 1 is installed and fixed when in use , the rotating base 2 and the cantilever 3 rotate synchronously for material picking and delivery.

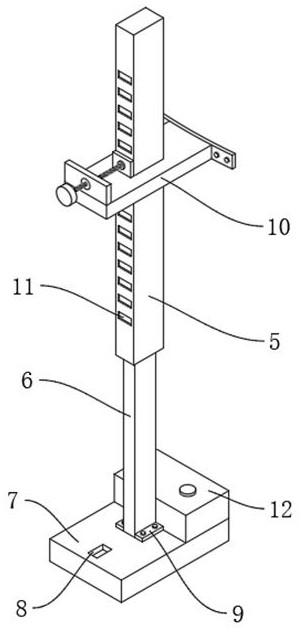

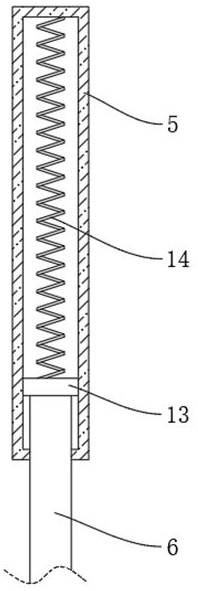

[0033] refer to Figure 1-2 , the rotating seat 2 is in the shape of a disc, the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com