Bamboo stick waste recovery device in motor maintenance

A waste recycling and bamboo stick technology, which is applied in the field of bamboo stick waste recycling devices in motor maintenance, can solve the problem of insulating paint affecting the secondary utilization of bamboo sticks and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

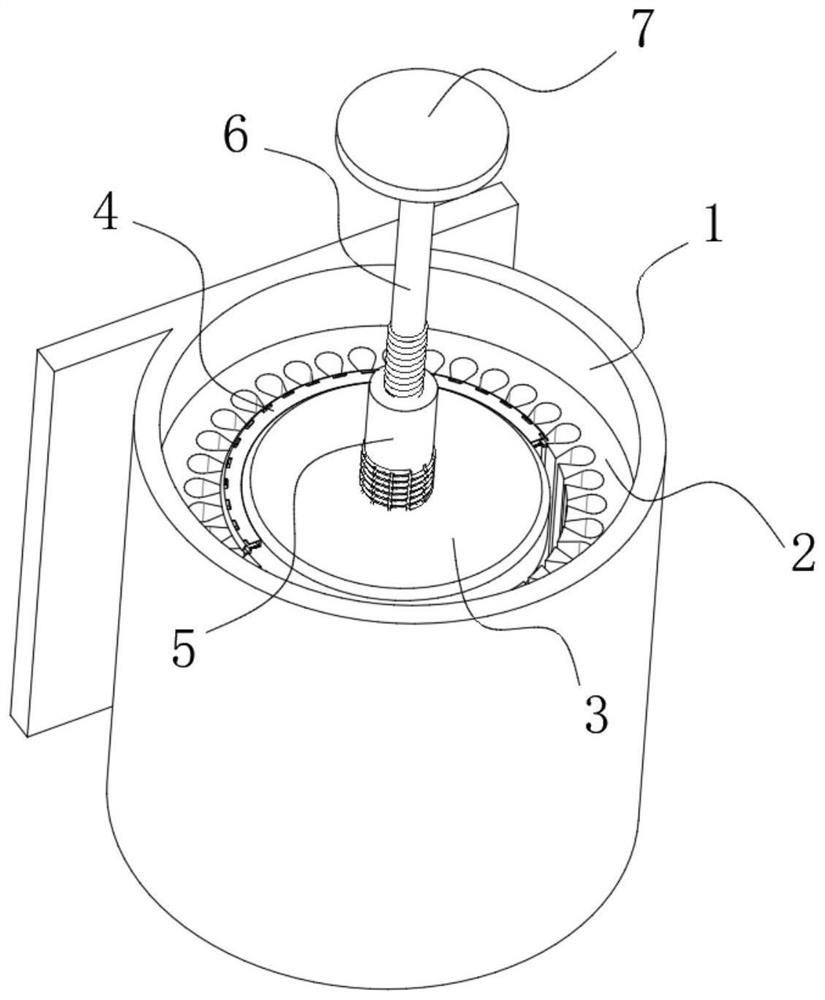

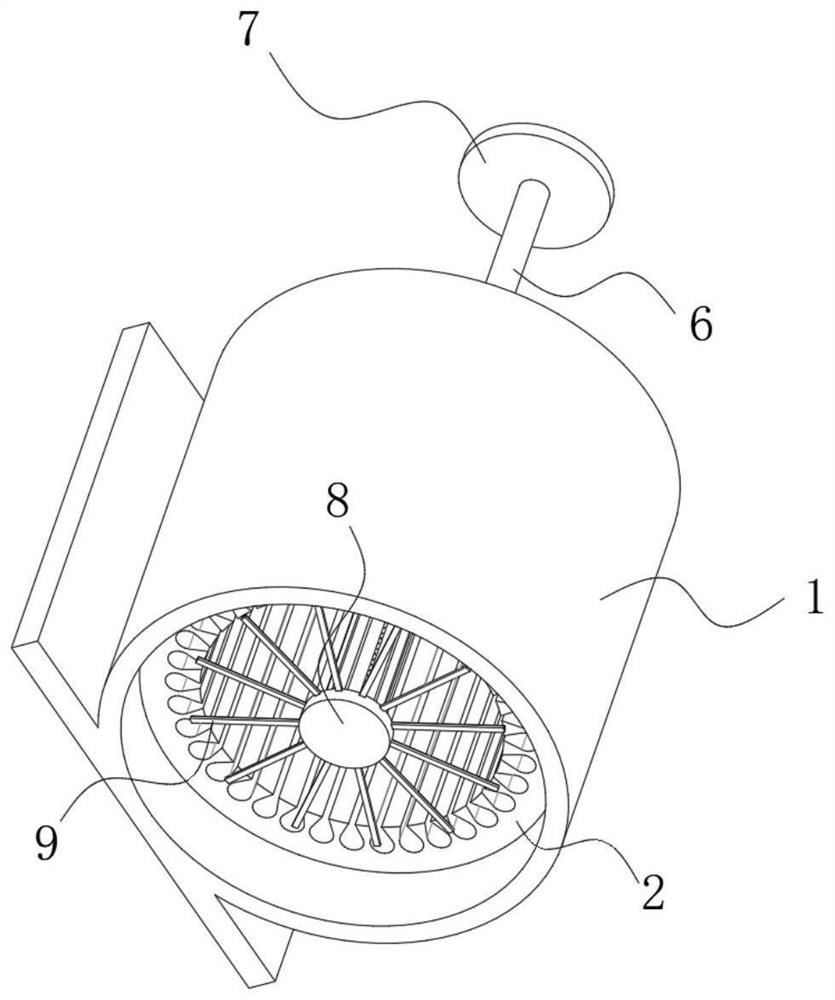

[0023] refer to Figure 1-6 , a bamboo stick waste recycling device in motor maintenance, comprising a motor casing 1 and a stator 2 installed in the motor casing 1, and a double helical lifting device is inserted in the stator 2.

[0024] The end of the stator 2 is provided with a top disk 3, and the double screw lifting device penetrates the top disk 3 and is threadedly connected with the top disk 3, so as to ensure that the rotating double screw lifting device rotates and lifts on the top disk 3, which can change the double screw lifting device in the stator. 2 in the position.

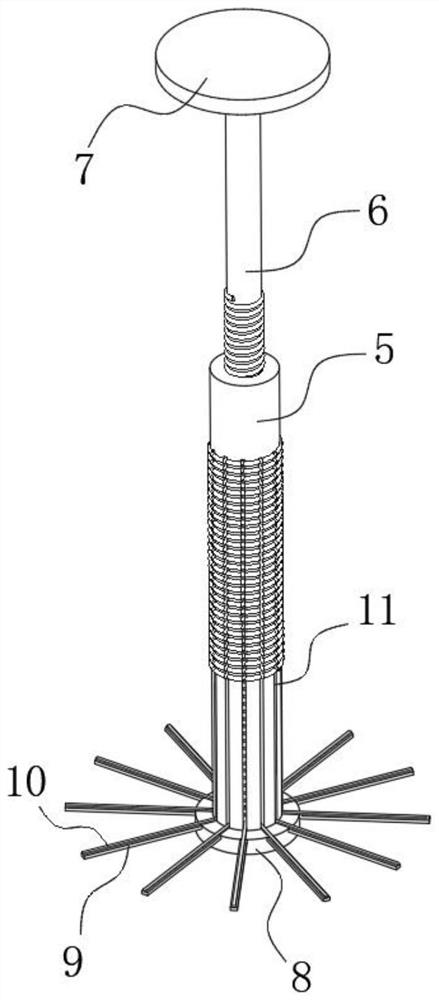

[0025] refer to image 3 , the double helical lifting device includes a first rotating rod 5, a second rotating rod 6, a top rotating handle 7, a bottom disc 8, a plurality of bottom support plates 9, a plurality of lifting rods 10 and a plurality of sliding holes 11, the bottom disc 8 is arranged at the bottom of the first rotating rod 5, and a plurality of bottom support plates 9 are circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com