Real-time dynamic monitoring equipment and real-time dynamic monitoring method for engineering cost

A monitoring equipment, real-time dynamic technology, applied in the direction of mechanical equipment, machine/support, supporting machine, etc., can solve the problems of difficult construction site shooting, inconvenient to adjust the camera angle of monitoring equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

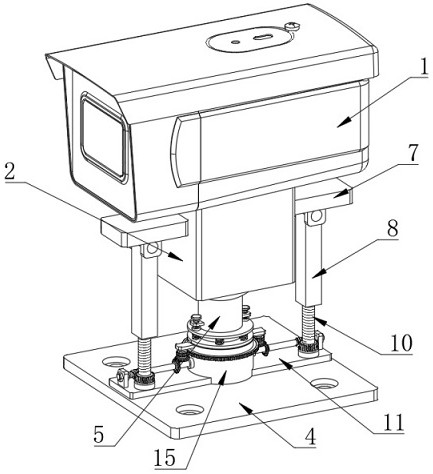

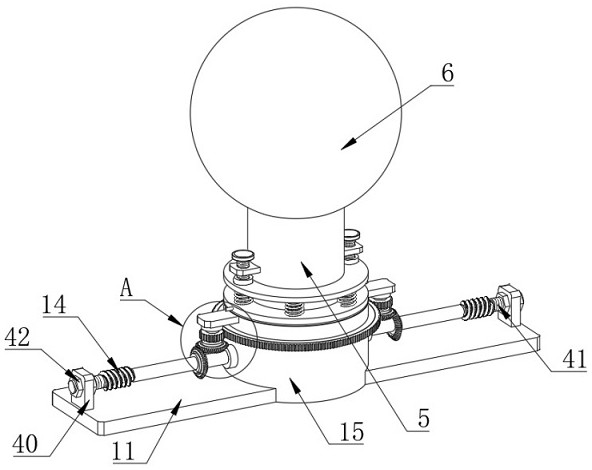

[0039] Example one, by Figure 1 to Figure 9 Given, the present invention includes a monitoring device body 1, the bottom of the monitoring device body 1 is fixedly connected with a fixed block 2, the bottom of the fixed block 2 is provided with a spherical groove 3, and a fixed seat 4 is arranged below the fixed block 2, and the bottom of the fixed seat 4 is provided. The top is fixedly connected with a support column 5, the top of the support column 5 is provided with a fixing ball 6, both sides of the fixing block 2 are fixedly connected with a first fixing plate 7, and a lifting plate 8 is arranged below the first fixing plate 7. The lifting plate 8 and the first fixing plate 7 are connected by a rotary slider, the bottom of the lifting plate 8 is provided with a threaded groove 9, the threaded groove 9 is provided with a first lead screw 10, and the fixed seat 4 is provided with a matching first lead screw 10. multi-directional monitoring and adjustment components;

[00...

Embodiment 2

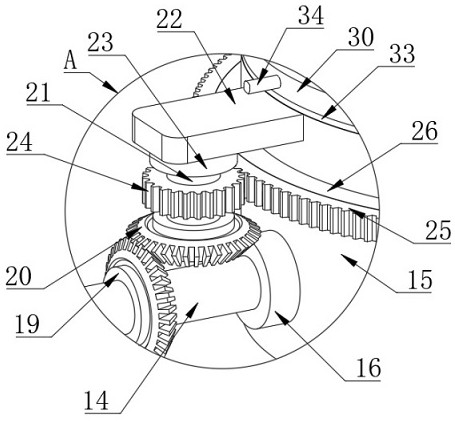

[0041] The second embodiment, on the basis of the first embodiment, is composed of figure 2 , image 3 and Image 6 Given, the synchronous rotation mechanism includes a first bevel gear 19 sleeved on the outside of the worm 14, the first bevel gear 19 is fixedly connected with the worm 14, a second bevel gear 20 is arranged above the worm 14, and the fixed sleeve 15 is on the Two second fixing plates 22 are fixedly connected, a rotating shaft 21 is arranged below the second fixing plate 22, the bottom end of the rotating shaft 21 is fixedly connected with the second bevel gear 20, and the top end of the rotating shaft 21 and the second fixing plate 22 pass through the second fixed plate 22. The three bearings 23 are connected, a first gear ring 24 is sleeved on the outside of the rotating shaft 21, the first gear ring 24 is fixedly connected with the rotating shaft 21, and the two first gear rings 24 are connected by a gear driver. The outer second gear ring 25, the second ...

Embodiment 3

[0042] Embodiment 3, on the basis of Embodiment 1, by figure 1 , figure 2 , Figure 4 and Figure 8 Given, the rotary slider includes a slider 28 arranged at the top of the lifting plate 8, the bottom of the first fixed plate 7 is provided with a chute 27, both sides of the lifting plate 8 are provided with side plates 29, the side plates 29 and the slider 28 is fixedly connected, and the side plate 29 and the lifting plate 8 are rotatably connected, the slider 28 is located in the chute 27, the cross-sections of the chute 27 and the slider 28 are T-shaped structures, and the fixed ball 6 is located in the spherical groove 3;

[0043] The two worms 14 are driven to rotate in opposite directions, so that the worms 14 drive the worm wheel 13 to rotate, and then the first lead screw 10 is driven to rotate through the worm wheel 13, so that the two first lead screws 10 rotate in opposite directions. The cooperation of the threaded grooves 9 changes the height of the lifting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com