Adjustable guide vane angle measuring mechanism for compensating deformation difference of double-layer casing

A technology of angle measurement and deformation difference, used in measurement devices, instruments, hydropower and other directions, can solve problems such as measurement errors and abnormal operation of adjustment mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

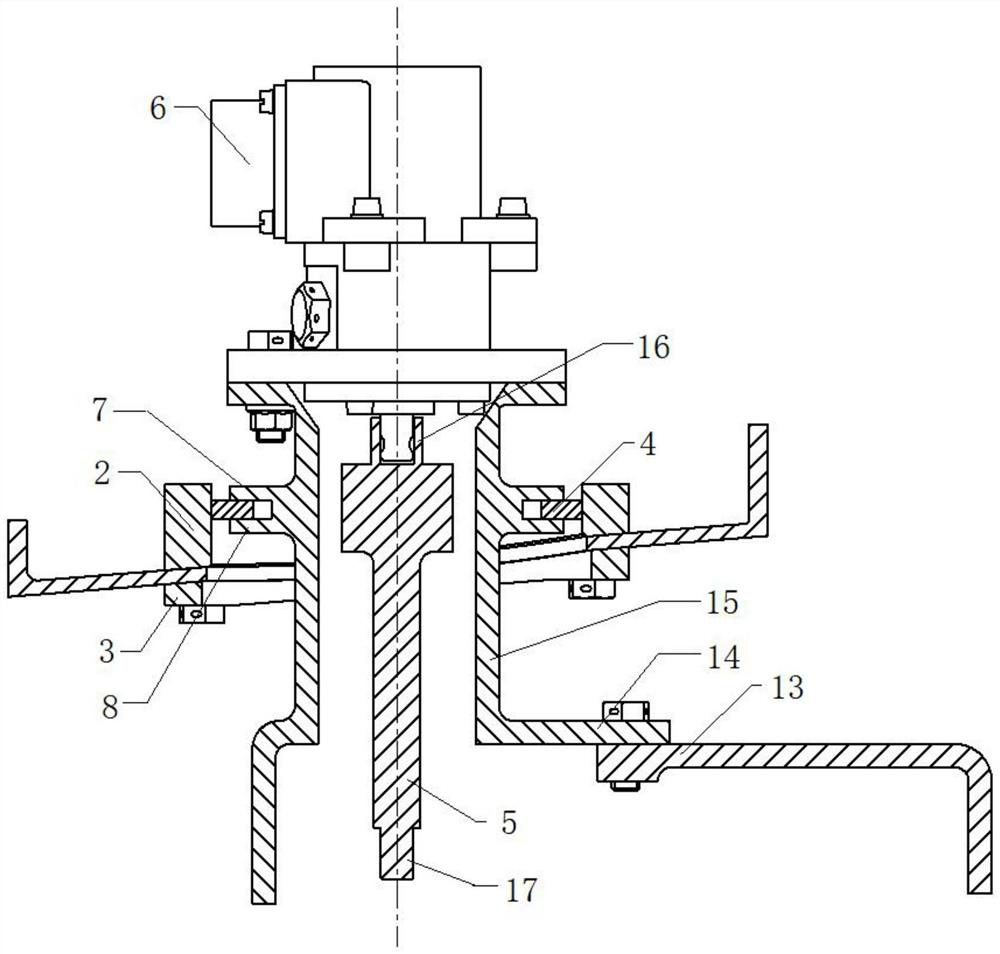

[0020] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

[0021] An adjustable guide vane angle measuring mechanism for compensating the deformation difference of a double-layer casing runs through the inner casing and the outer casing of the engine, the inner casing is provided with a rotor and a stator, the rotor is provided with rotor blades, and the stator is provided with a rotor and a stator. An adjustable blade is arranged on the upper part, and the rotating shaft of the adjustable blade can adjust the angle of the blade under the adjustment of the adjustment mechanism.

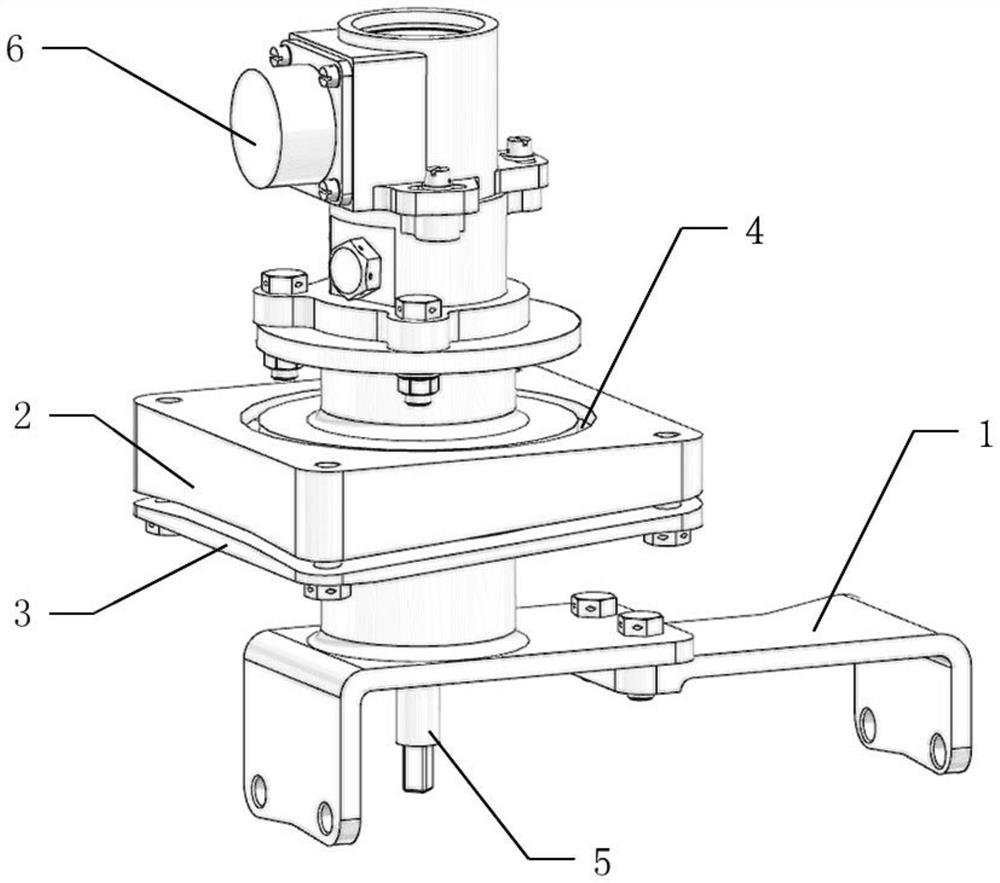

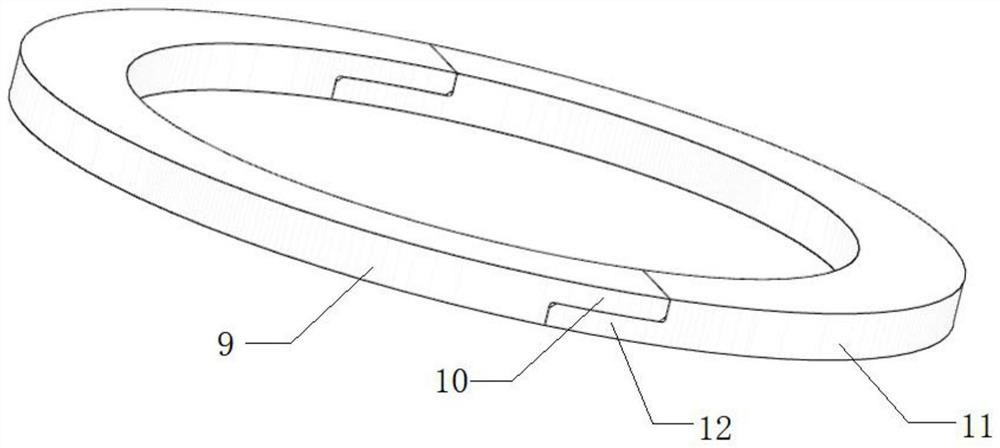

[0022] like figure 1 , figure 2 As shown, it includes a fixed frame 1, an intermediate shaft 5, an angular displacement sensor 6 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com