Defect detection device for large-breadth silk screen

A defect detection and surface screen technology, which is applied in the direction of measuring devices, instruments, and final product manufacturing, can solve problems such as low efficiency, difficulty in identification, and insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

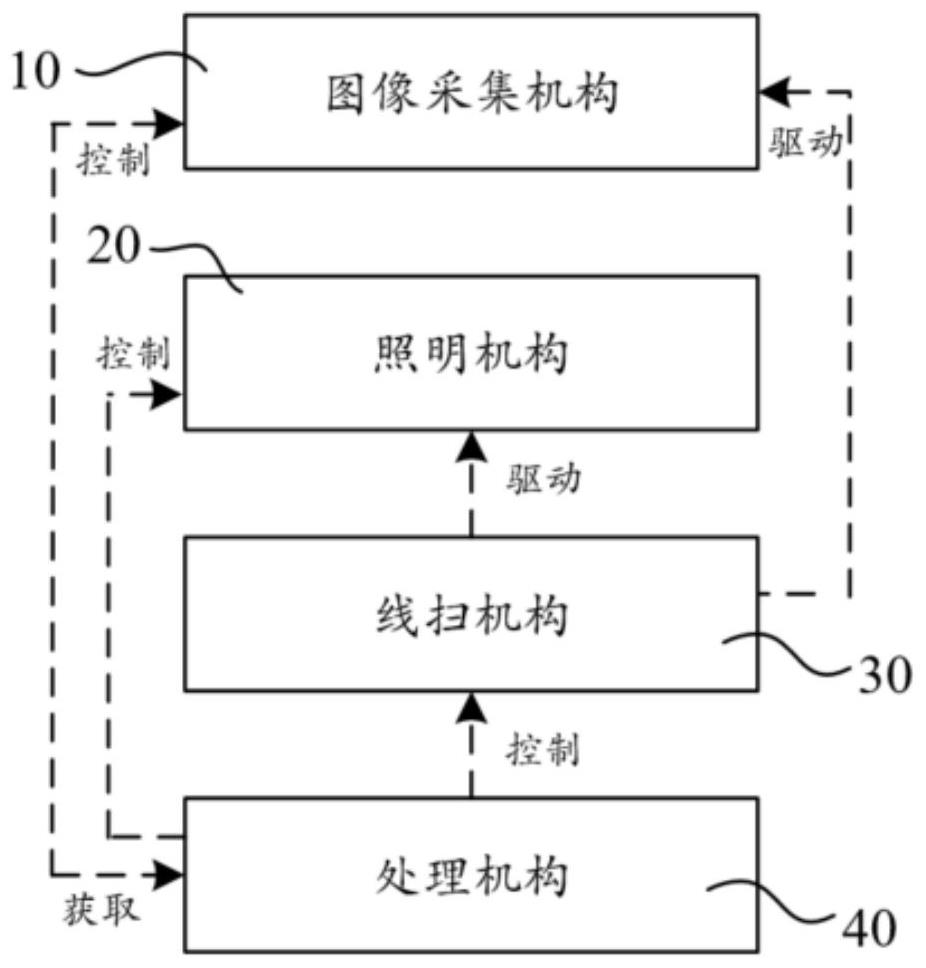

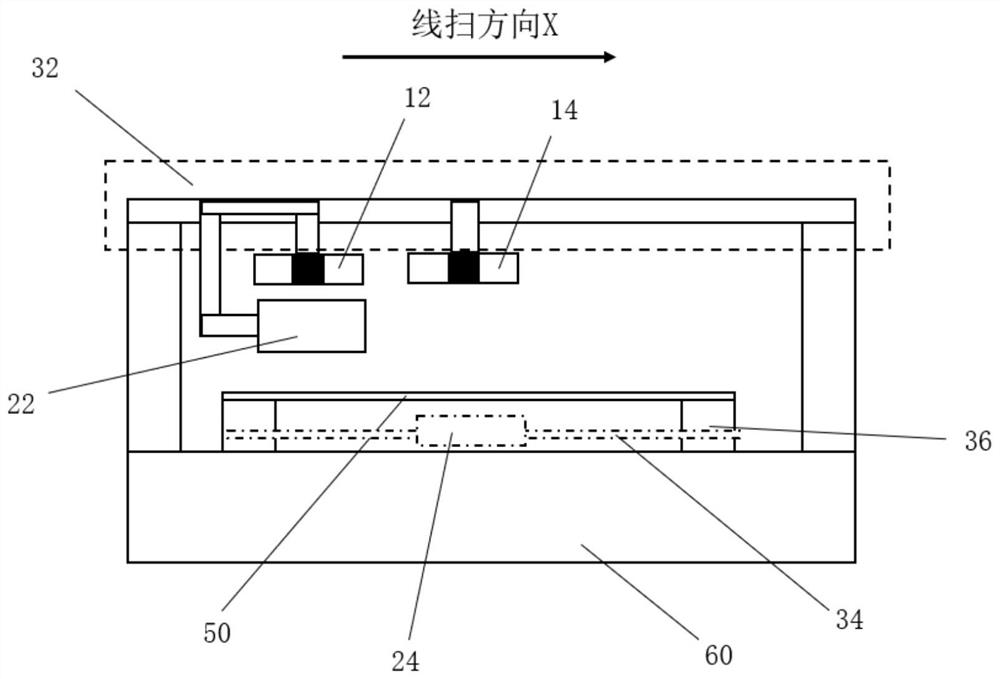

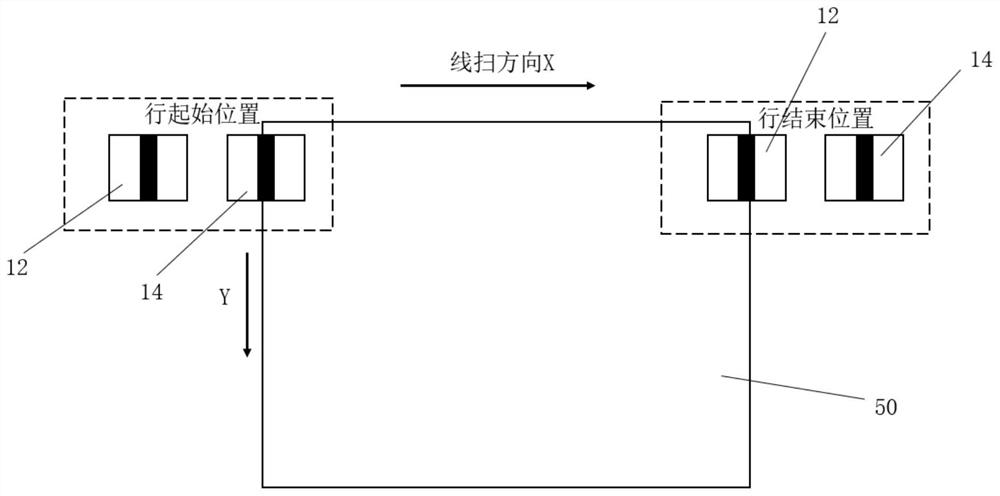

[0036] figure 1 It is a schematic structural diagram of a large-format wire mesh defect detection device provided by an embodiment of the present invention, such as figure 1 As shown, the present invention provides a large-format wire mesh defect detection device, including a support machine 60 and a clamping mechanism (not shown in the figure) arranged in the support machine 60, an image acquisition mechanism 10, and an illumination mechanism 20. , line sweeping mechanism 30 and processing mechanism 40 .

[0037] The clamping mechanism is used to place and fix the wire mesh 50 to be tes...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap