Pipe core of stencil paper cylinder for mimeograph and retainer

A technology for cages and tubes, applied in printing plates, foils, printing, etc., can solve the problems of expensive tube core manufacturing, precise and inconvenient tube core processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will now be described in detail with reference to the accompanying drawings showing embodiments, but this does not limit the scope of the present invention. In this connection, the component parts of the embodiment of the present invention having the same functions as those in the above-mentioned conventional art are denoted by the same reference numerals.

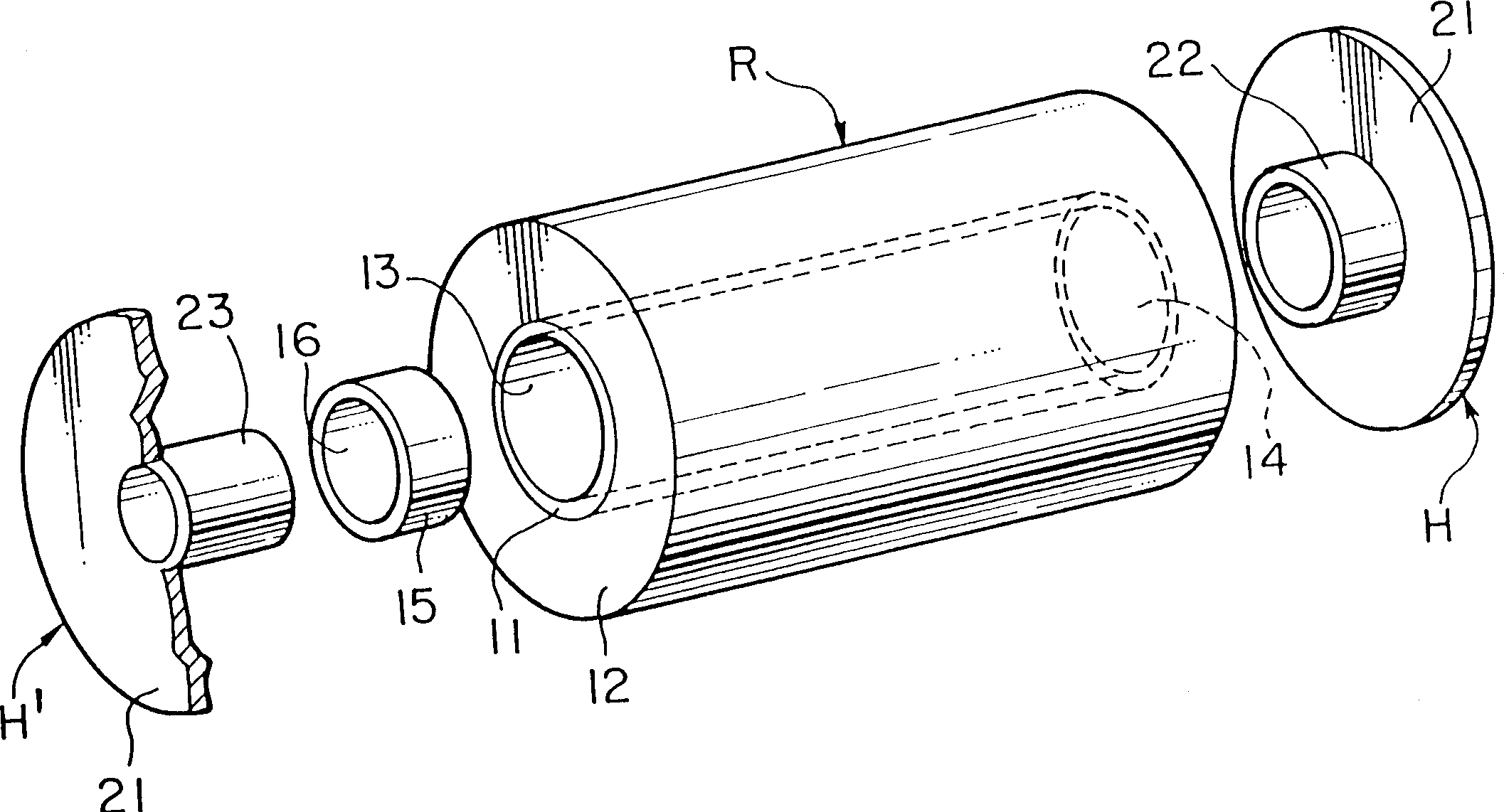

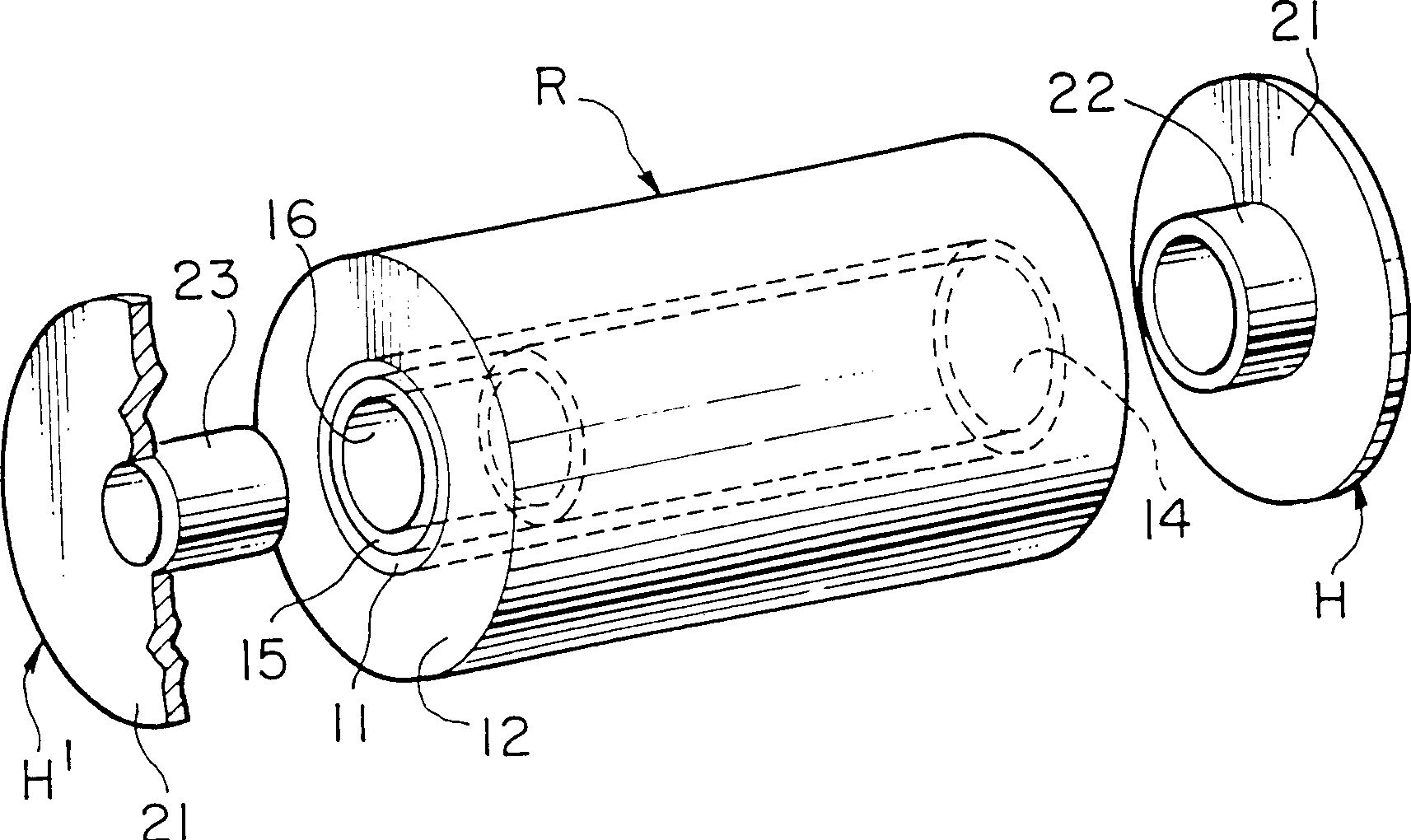

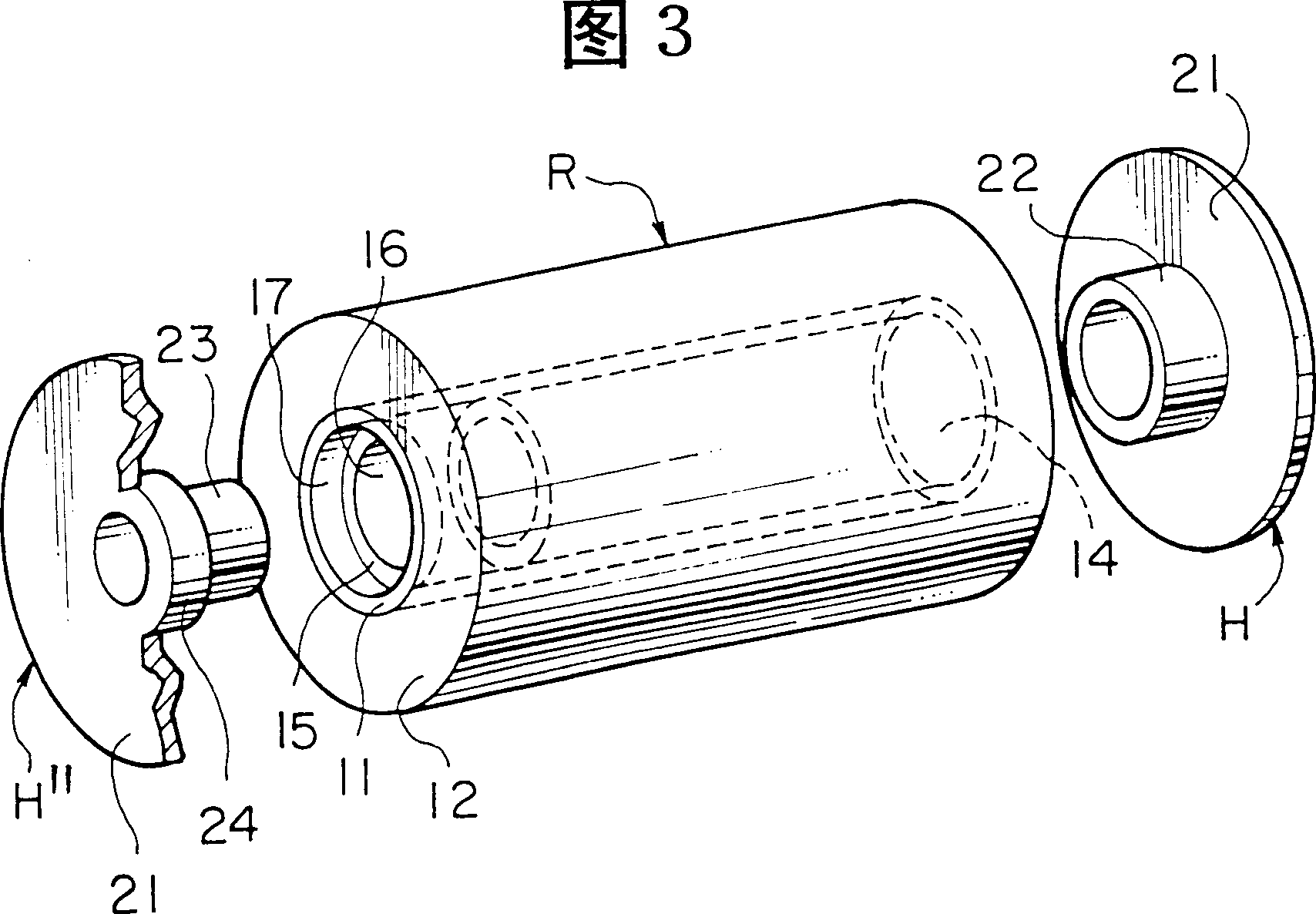

[0021] First, refer to the attached figure 1 with 2 , schematically illustrates a first embodiment of the present invention. exist figure 1 Among them, the stencil roll R is formed by winding the length of the stencil paper 12 around the first tube 11 formed of paper or cardboard and shaped as a cylindrical hollow tube with both ends open. This structure is the same as that of the conventional stencil roll R shown in FIG. 5 . The first tube 11 has a right end opening 14 to which a holder H similar to that of FIG. 5 is fitted in use. The holder H has a cylindrical short tubular boss 22 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com