Fin-type heat exchanger

A technology of heat exchangers and fins, applied in the field of finned heat exchangers, can solve problems such as uneven air, increased manufacturing costs, and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will now be described with reference to the accompanying drawings.

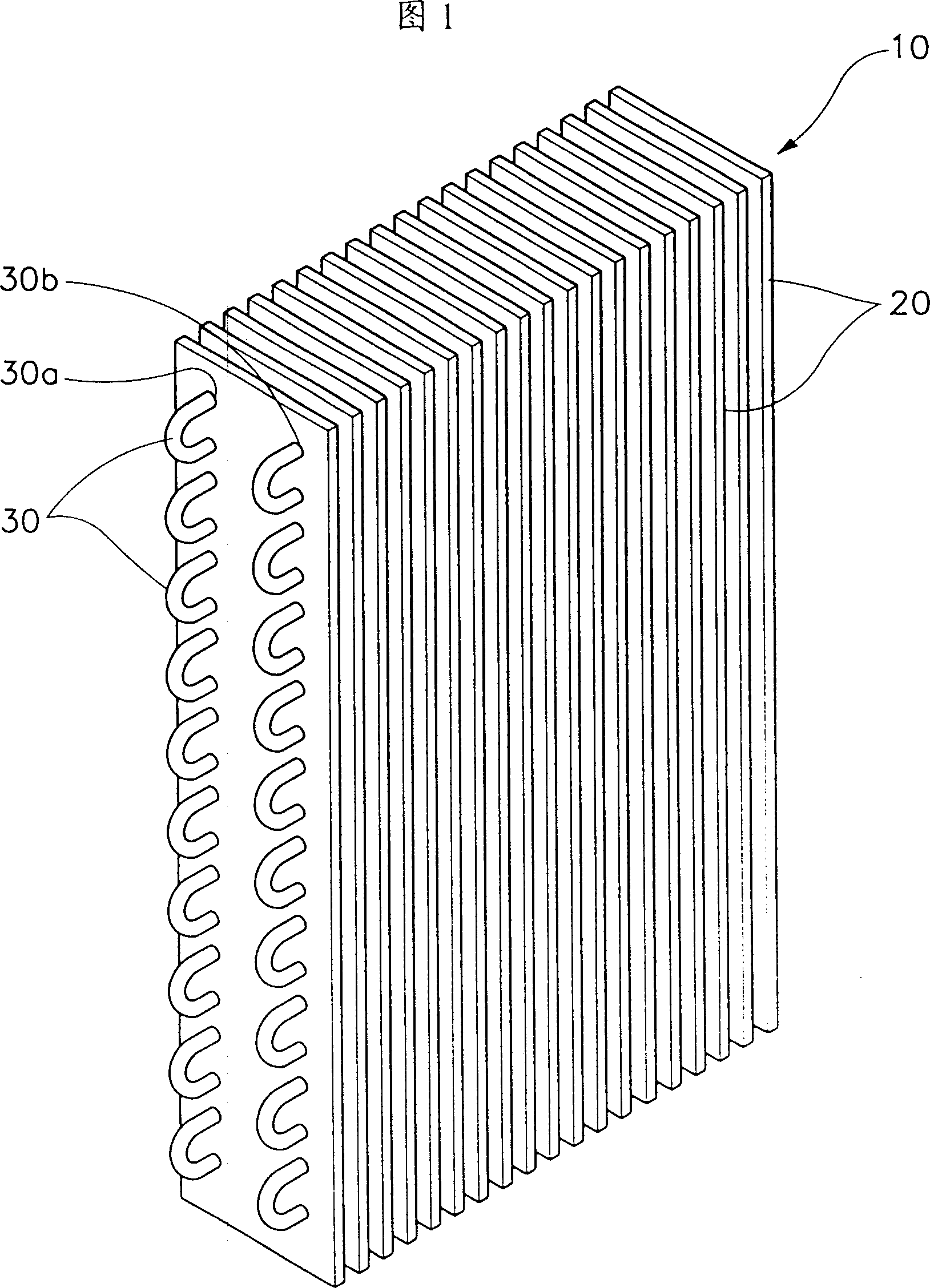

[0028] Referring first to Figure 1, there is shown a perspective view of a finned heat exchanger 10 of the present invention. The heat exchanger 10 includes a plurality of plate-shaped fins 20 arranged parallel to each other at predetermined intervals, the fins 20 having at least two rows of tube holes 30a and 30b formed along the length of the fins 20 at predetermined intervals, one tube 30 Inserted into the tube holes 30 a and 30 b by bending on the outside of the heat exchanger 10 . Refrigerant or other working fluid passes through the tubes 30, exchanging heat with the air across the outer surfaces of the tubes 30 and fins 20, which act as an intermediary.

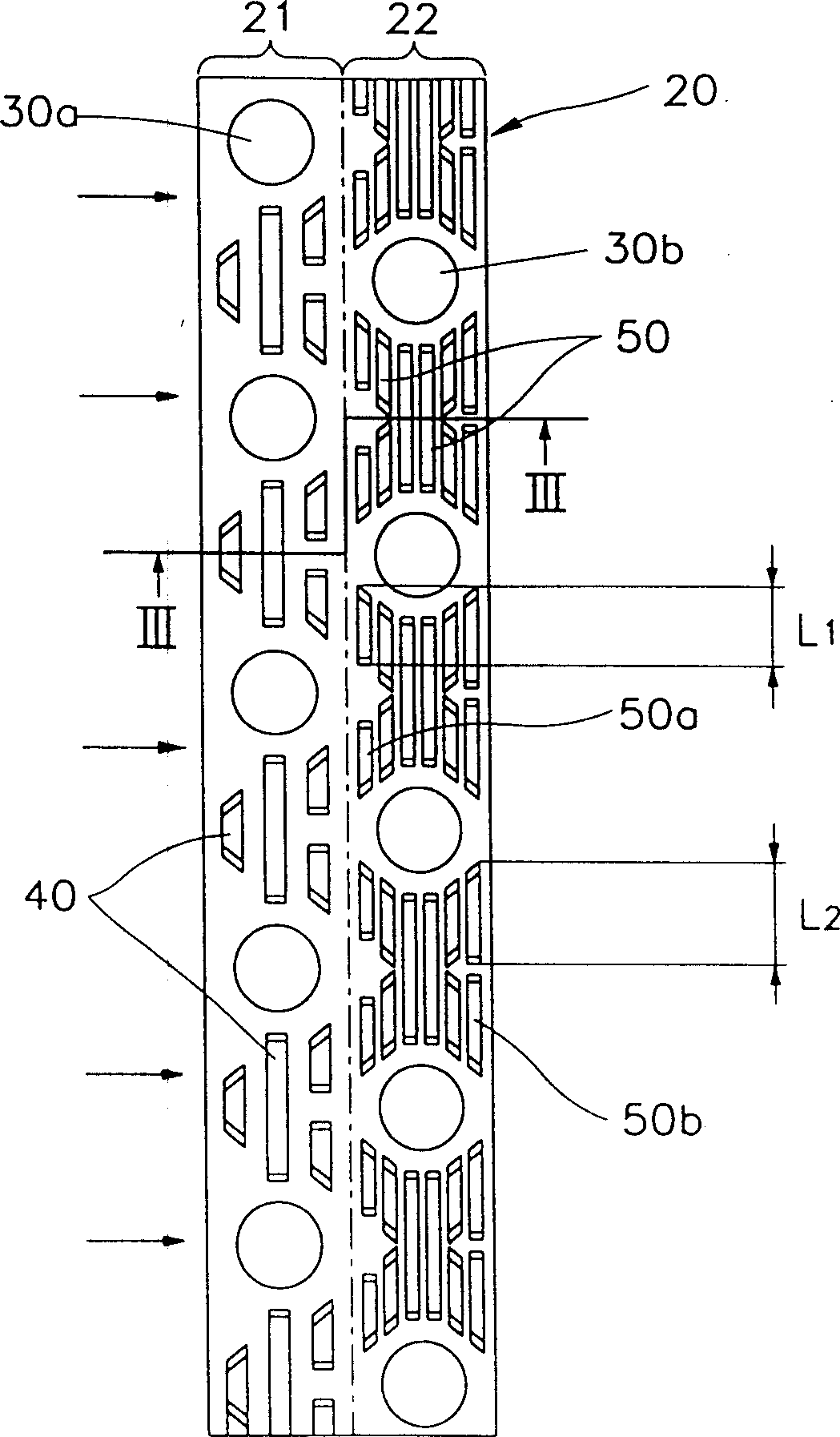

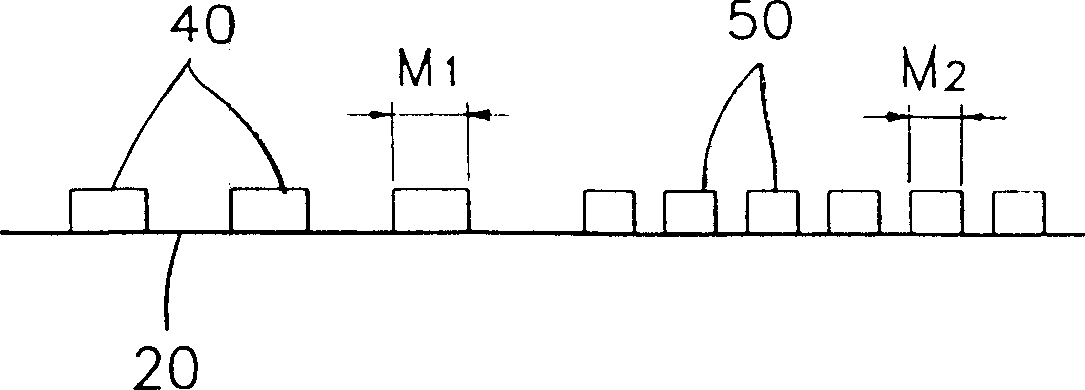

[0029] figure 2 It is a plan view of one of the fins 20 shown in Fig. 1, as shown in the figure, the fin 20 is divided into two sides: a suction side 21, on this side, the tube holes 30a form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com