Hydrostatic bearing

A hydrostatic bearing, hydrostatic technology, applied in the direction of hydrostatic bearing, bearing, shaft and bearing, etc., can solve the problem that there is no hemispherical surface for reliable lubrication and self-alignment cannot be ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The same components are denoted by the same reference numerals.

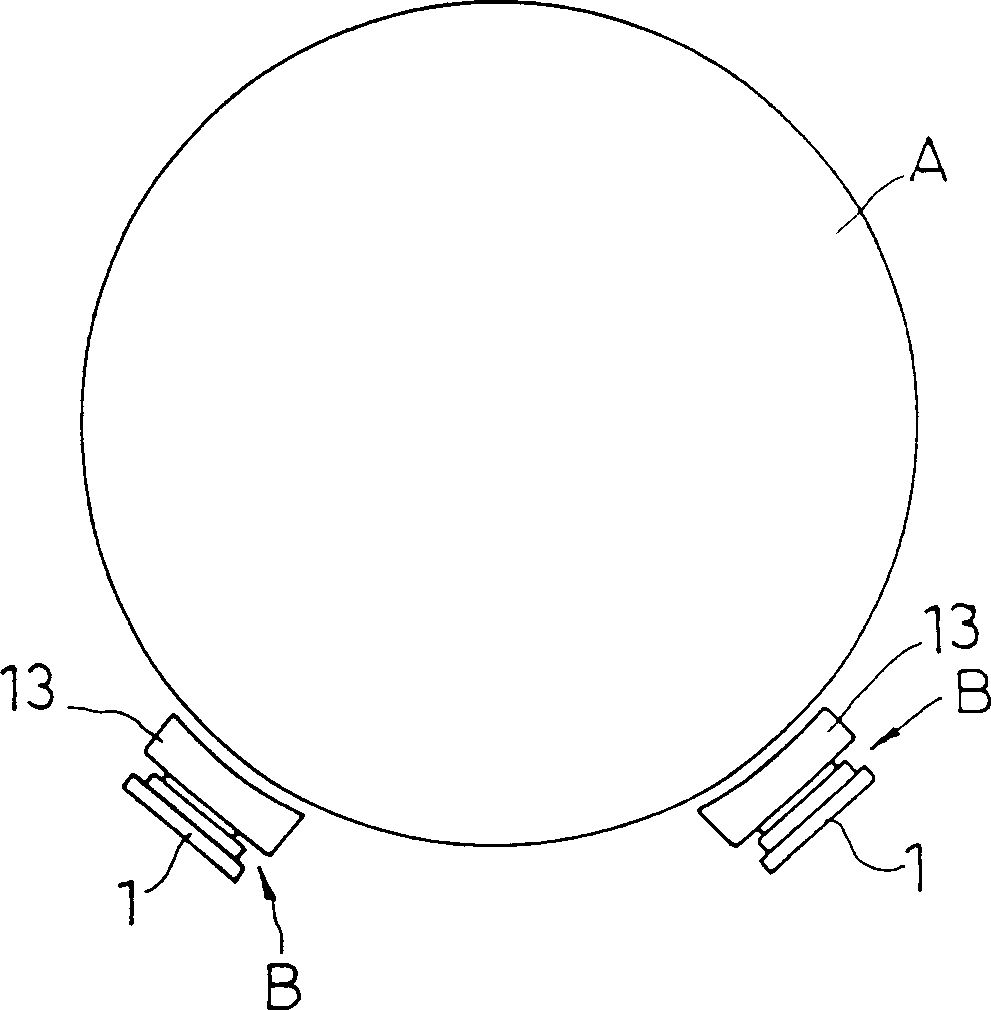

[0032] Fig. 1 schematically shows a hydrostatic bearing according to an embodiment of the present invention used as a radial bearing. In Fig. 1, A denotes a shaft to be supported, and B denotes a hydrostatic bearing device, which supports the shaft A rotatably in pairs. The pair of static pressure bearing devices B are obliquely placed on the left and right sides below the axis A.

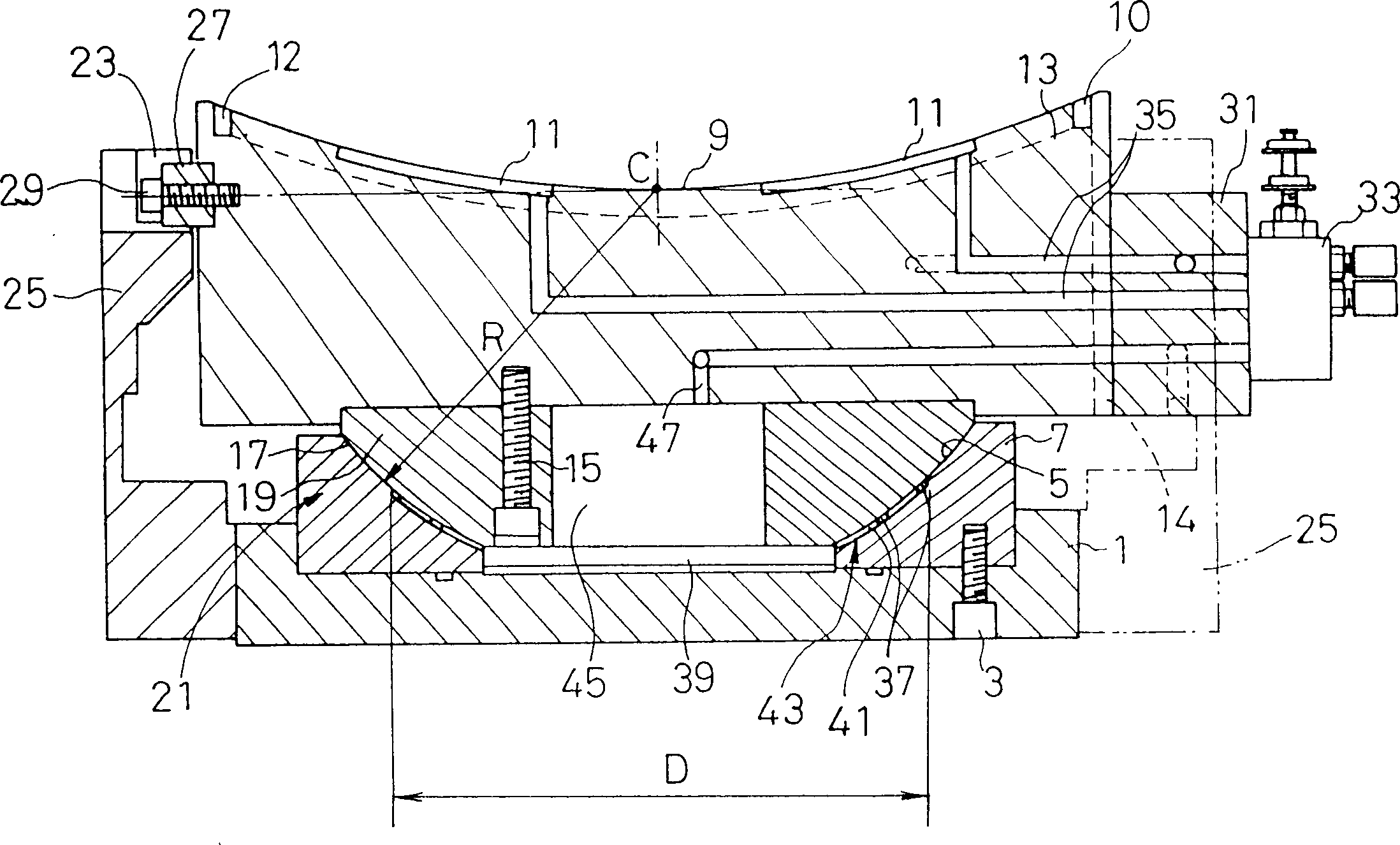

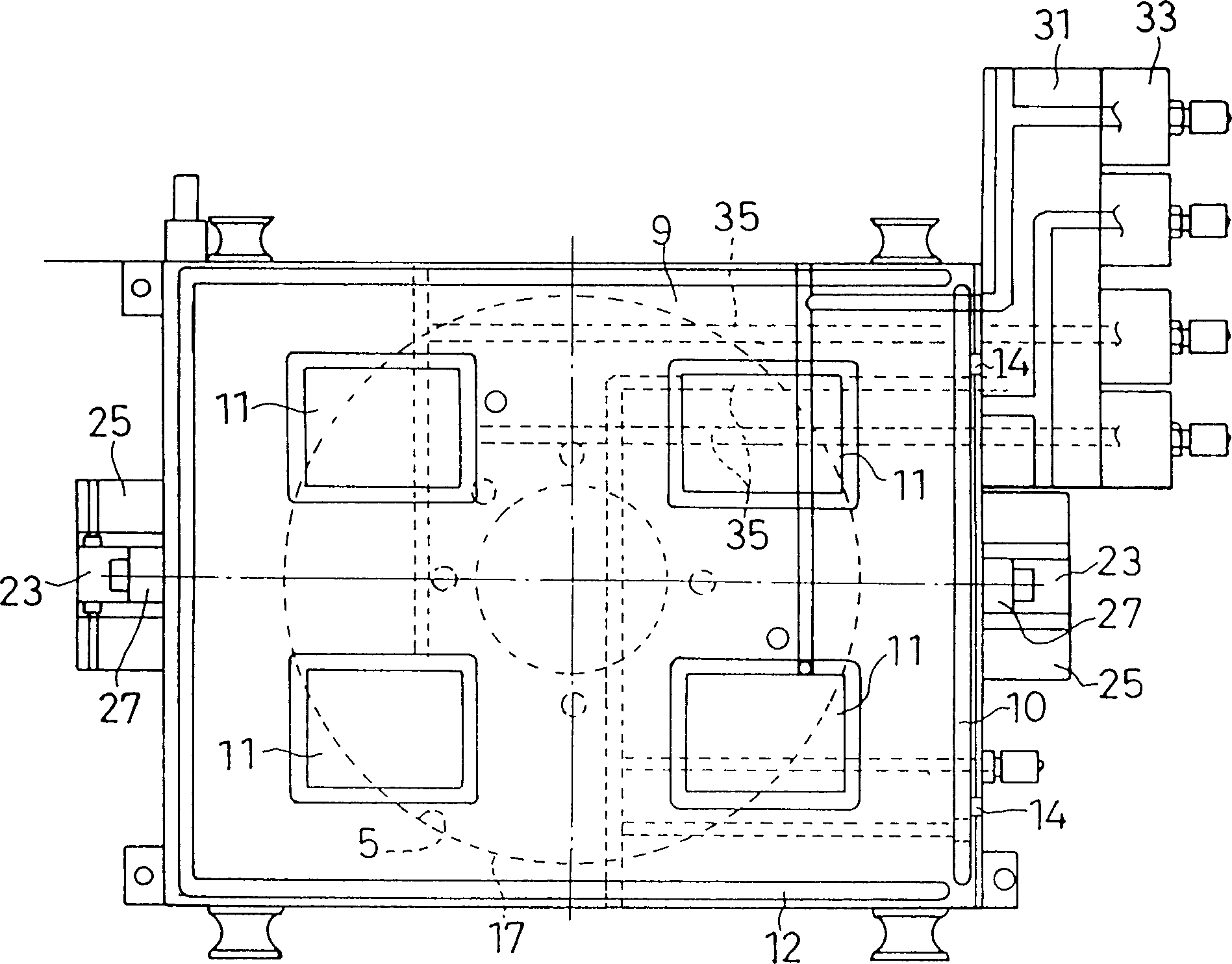

[0033] 2, 3 and 4 are a longitudinal sectional view, a top view and a side view of the hydrostatic bearing device B, respectively. The device B includes: a substantially flat bearing seat 1; a concave spherical lower (supporting) support member 7, the top surface of which is basically a hemispherical or hemispherical annular spherical surface 5, and a bolt (in this figure) Table 3) fastened to the concave to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com