Micronano copper powder and preparation method thereof

A micro-nano, copper powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unsatisfactory preparation repeatability, poor particle uniformity, and equal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0094] (1) Weigh 0.15 g of copper chloride and dissolve it in 500 mL of water to make a solution, add 224 g of potassium hydroxide under strong stirring conditions, and keep stirring for 4 hours at 60 ° C to obtain system A;

[0095] (2) Weigh 0.2 g of citric acid, 3 g of ascorbic acid, 0.5 mL of ammonia water, 0.1 g of PVA, 0.3 g of lysine and 10 mL of methanol and dissolve them in 200 mL of water, add them to system A to obtain system B, and put system B at 90 ° C Under the conditions, the reaction was continued for 48 hours, the reaction was stopped, the reactants were centrifuged, washed repeatedly, and finally dried in a vacuum oven to obtain a sample-copper powder A.

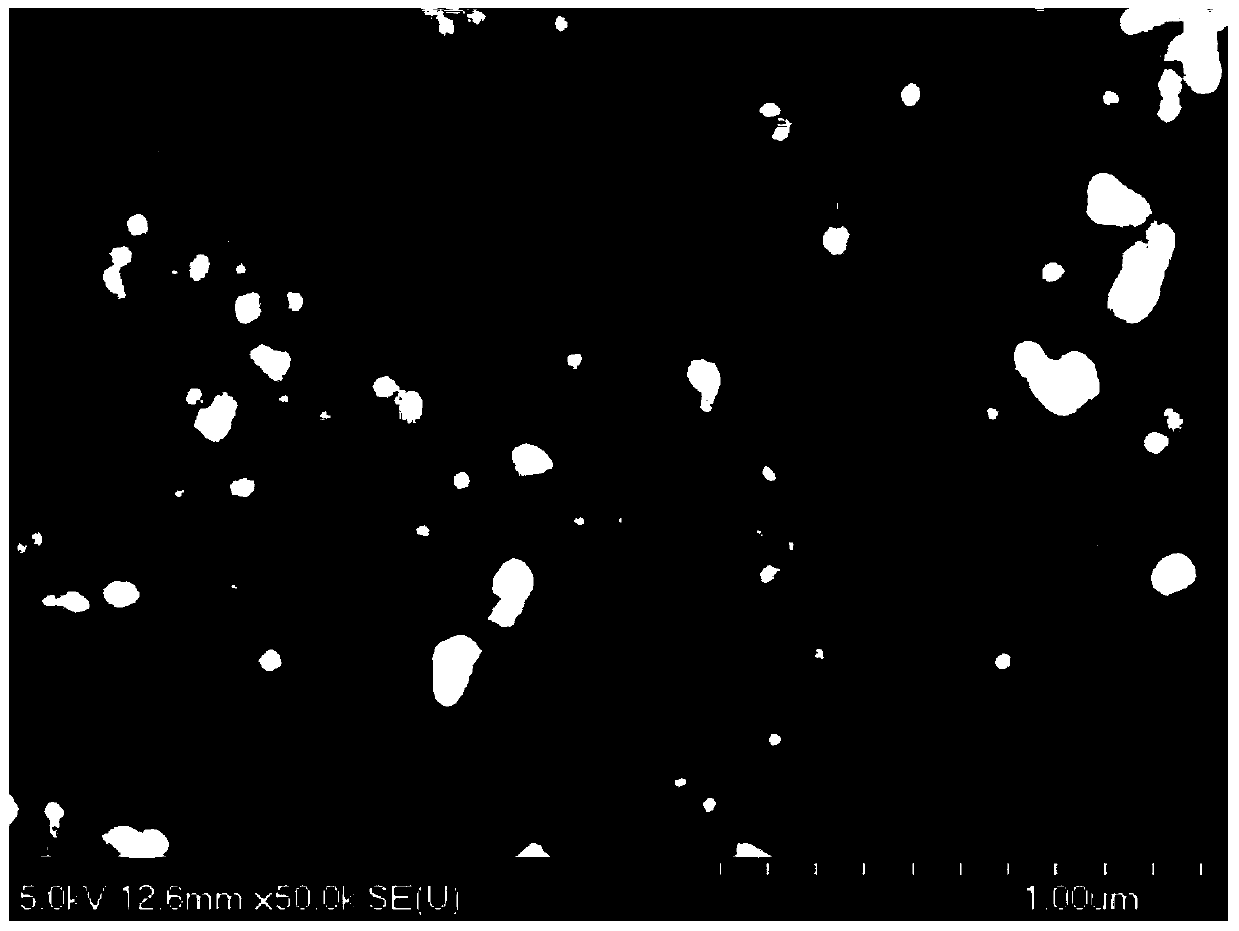

[0096] Adopt scanning electron microscope to observe the morphology of sample-copper powder A, the result sees figure 1 ,from figure 1 It can be seen that the copper particles...

Embodiment 2

[0098] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0099] (1) Weigh 6.0 grams of copper chloride and dissolve it in 500 mL of water to make a solution, add 340 grams of potassium hydroxide under strong stirring conditions, and keep stirring for 4 hours at 60°C to obtain system A;

[0100] (2) Weigh 3.2 grams of citric acid, 50 grams of ascorbic acid, 30 grams of maltose, 1 mL of ammonia water, 2 mL of diethylenetriamine, 1 gram of PVA and 15 mL of ethanol and dissolve them in 200 mL of water, and add them to system A to obtain system B. Under the condition of 90°C, the reaction was continued for 48h. The reaction was stopped, and the reactants were centrifuged, washed repeatedly, and finally dried in a vacuum oven to obtain a sample-copper powder B.

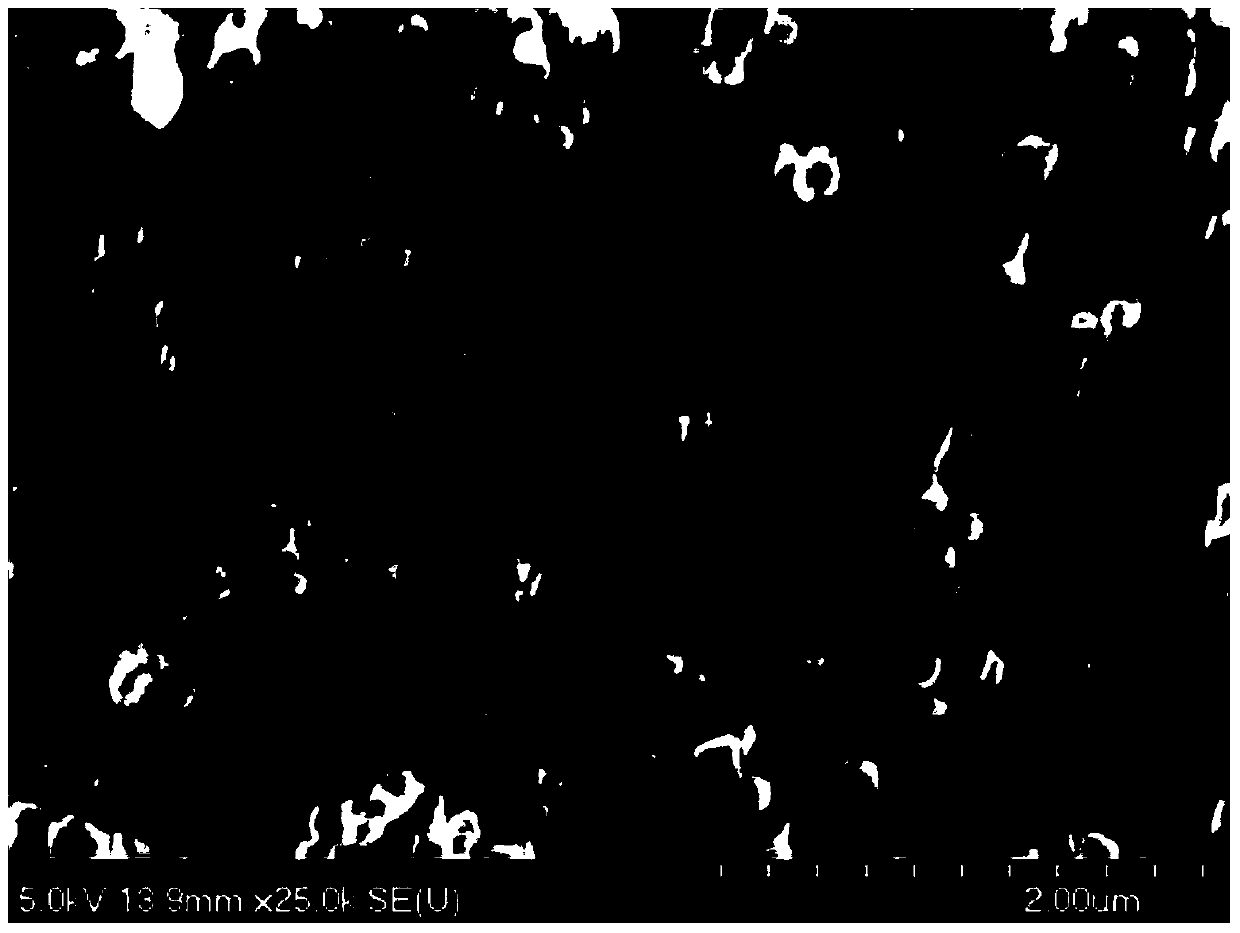

[0101] Adopt scanning electron microscope to observe the morphology of sample-copper powder B, the results can be found in figure 2 ,from figure ...

Embodiment 3

[0103] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0104] (1) Weigh 125 grams of copper sulfate and dissolve it in 1000 mL of water to make a solution, add 400 grams of sodium hydroxide, 10 grams of sodium carbonate and 6 grams of urea under strong stirring conditions, and continue stirring for 12 hours at 60 ° C to obtain System A;

[0105] (2) Weigh 50 grams of D-xylose, 340 grams of lactose, 200 grams of sucrose, 10 grams of ammonium chloride, 5 grams of glutamic acid, 3 grams of PEG and 30 mL of ethanol, dissolve them in 1000 mL of water, add them to system A to obtain the system B, the temperature of system B was rapidly raised to 130°C by microwave heating, the reaction was continued for 2 minutes, and the reaction was stopped. The reactant was filtered, washed repeatedly, and finally dried in a vacuum oven to obtain sample-copper powder C.

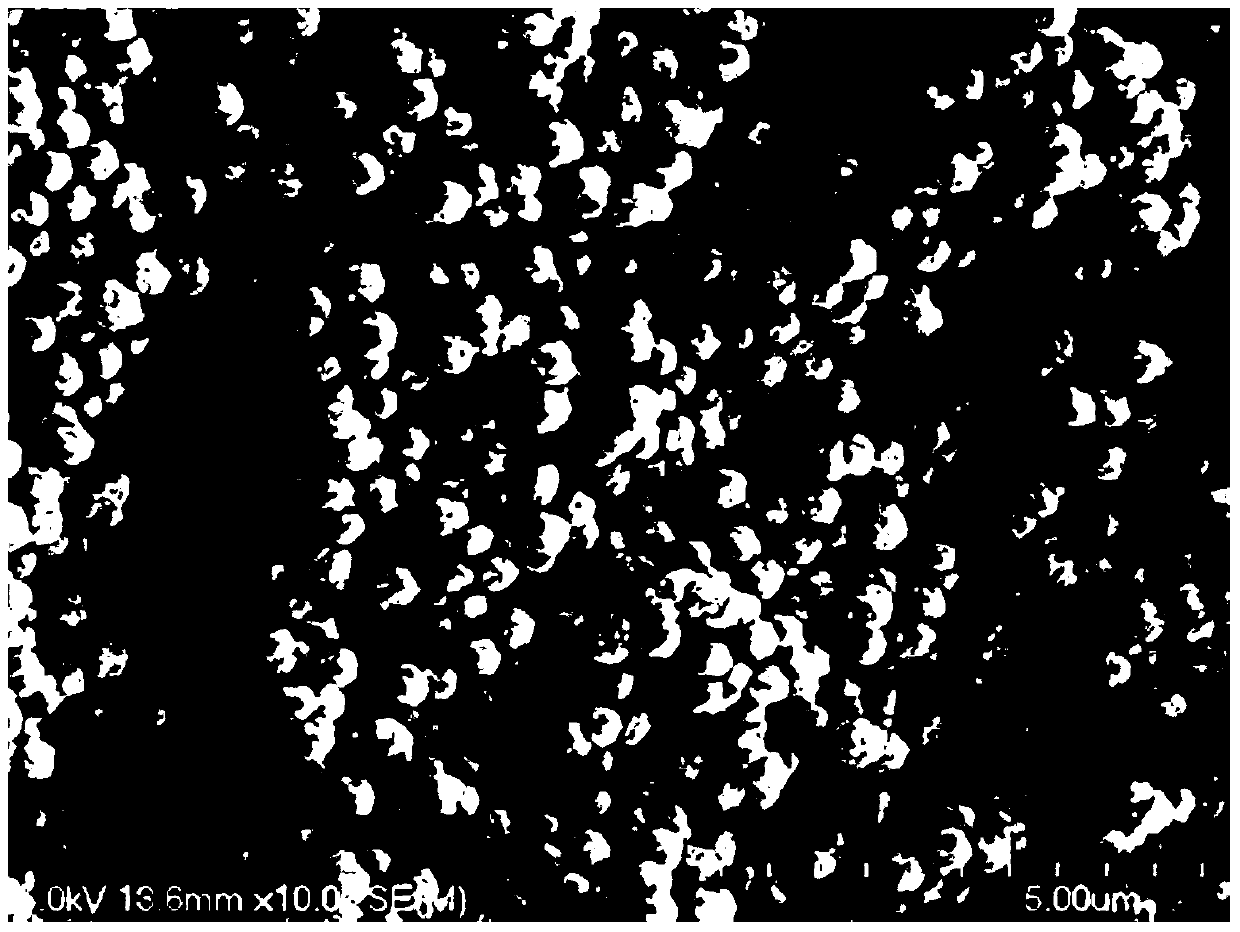

[0106] Adopt scanning electron microscope to obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com