Device in valve

A valve and valve housing technology, applied in the field of devices in valves, can solve the problems of complex and expensive device manufacturing, and achieve the effects of low pressure gradient, reduced risk of vibration, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

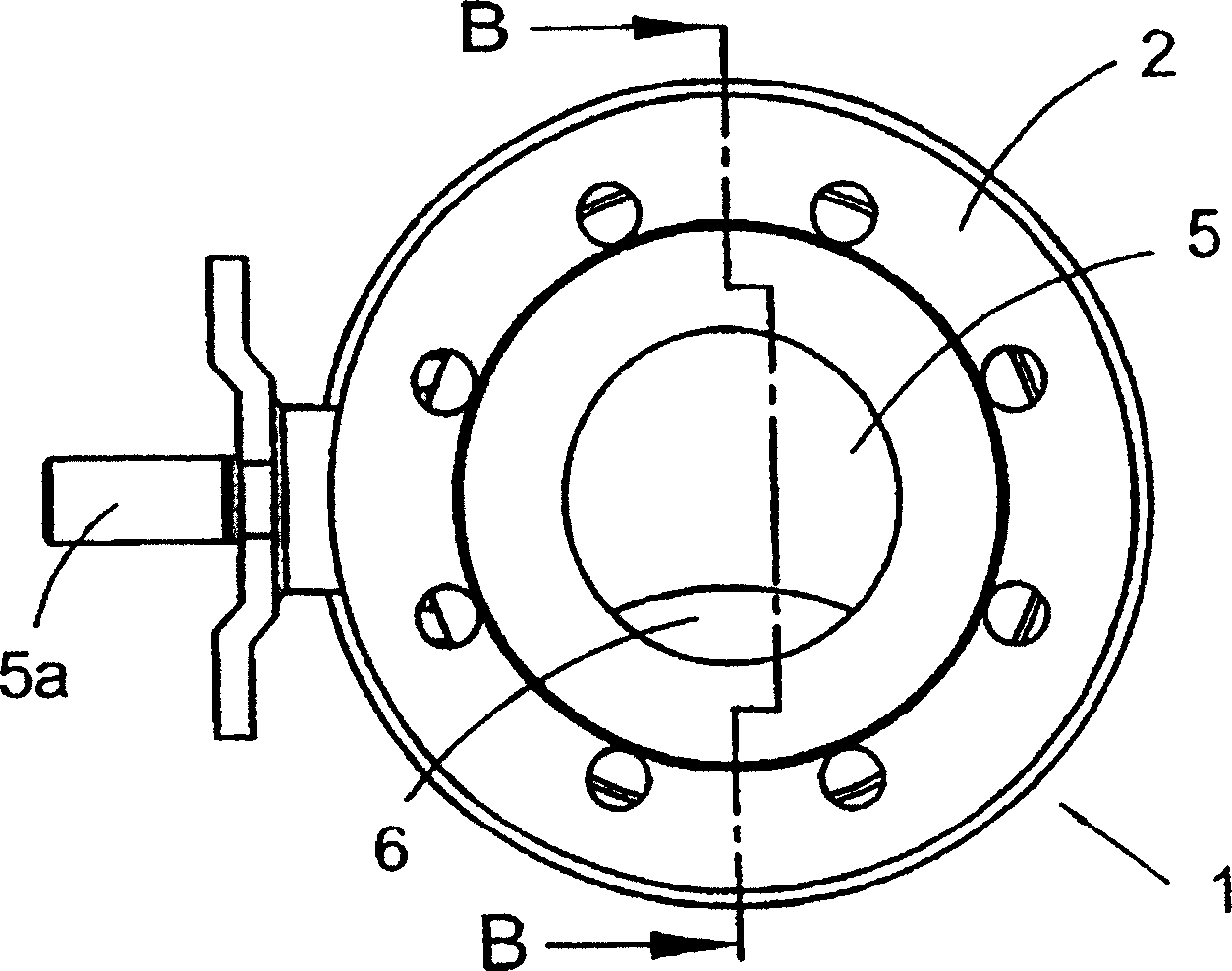

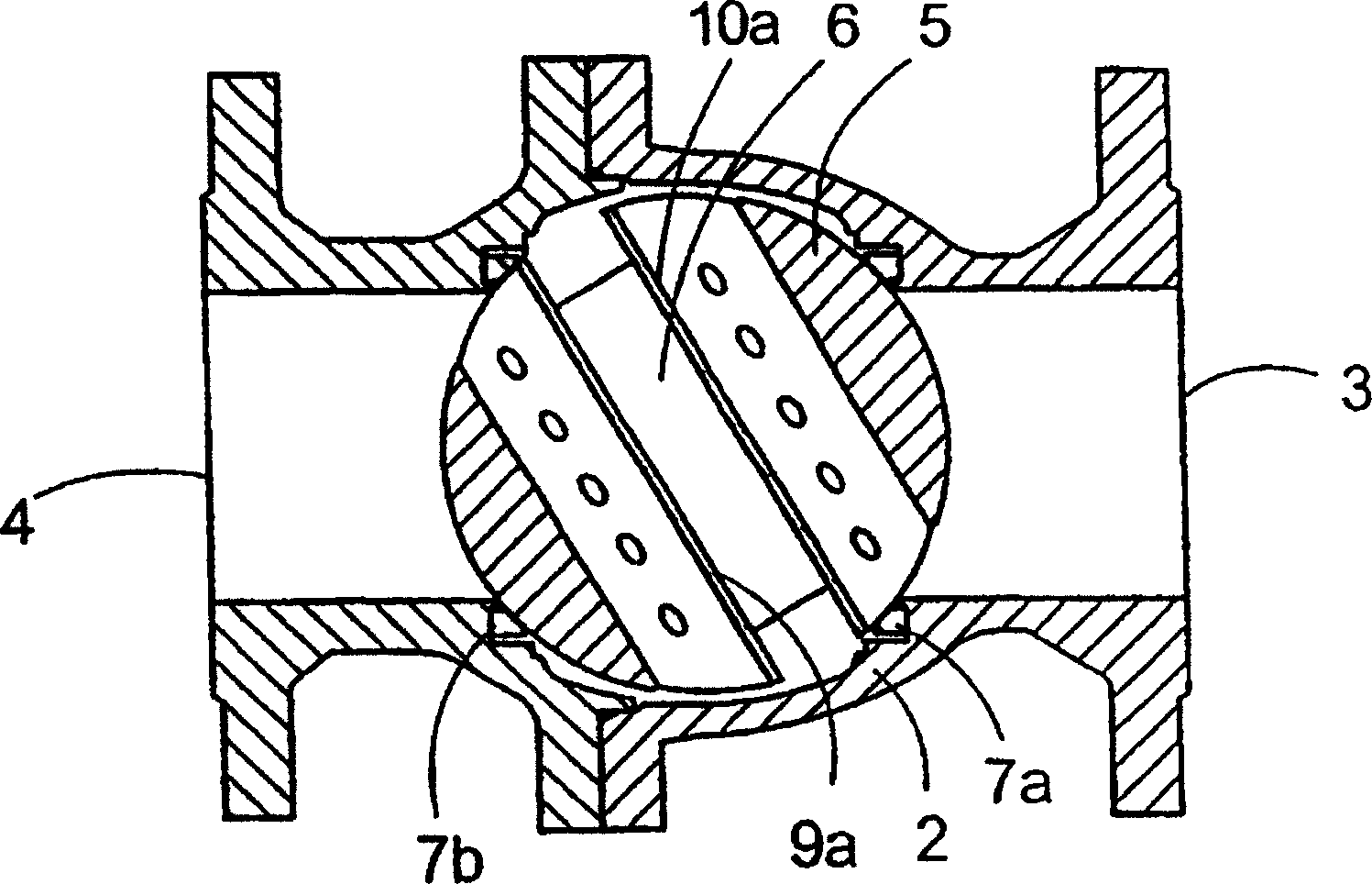

[0013] The spherical valve 1 comprises a valve housing 2 on opposite sides of which an inlet 3 and an outlet 4 are arranged. A valve body 5 with a substantially cylindrical passage 6 is pivotally mounted inside the valve housing 2 . Figure 1a A shaft 5a connected to the valve body 5 for operating the valve body 5 is shown. In the fully open position of the valve 1, the inlet 3 and outlet 4 and the channels are in line with each other. Figure 1b Also shown are two annular seals 7a, 7b for sealing between the inlet 3 and outlet 4 and the valve body 5 respectively. Those skilled in the art will appreciate that in some applications only one seal is required.

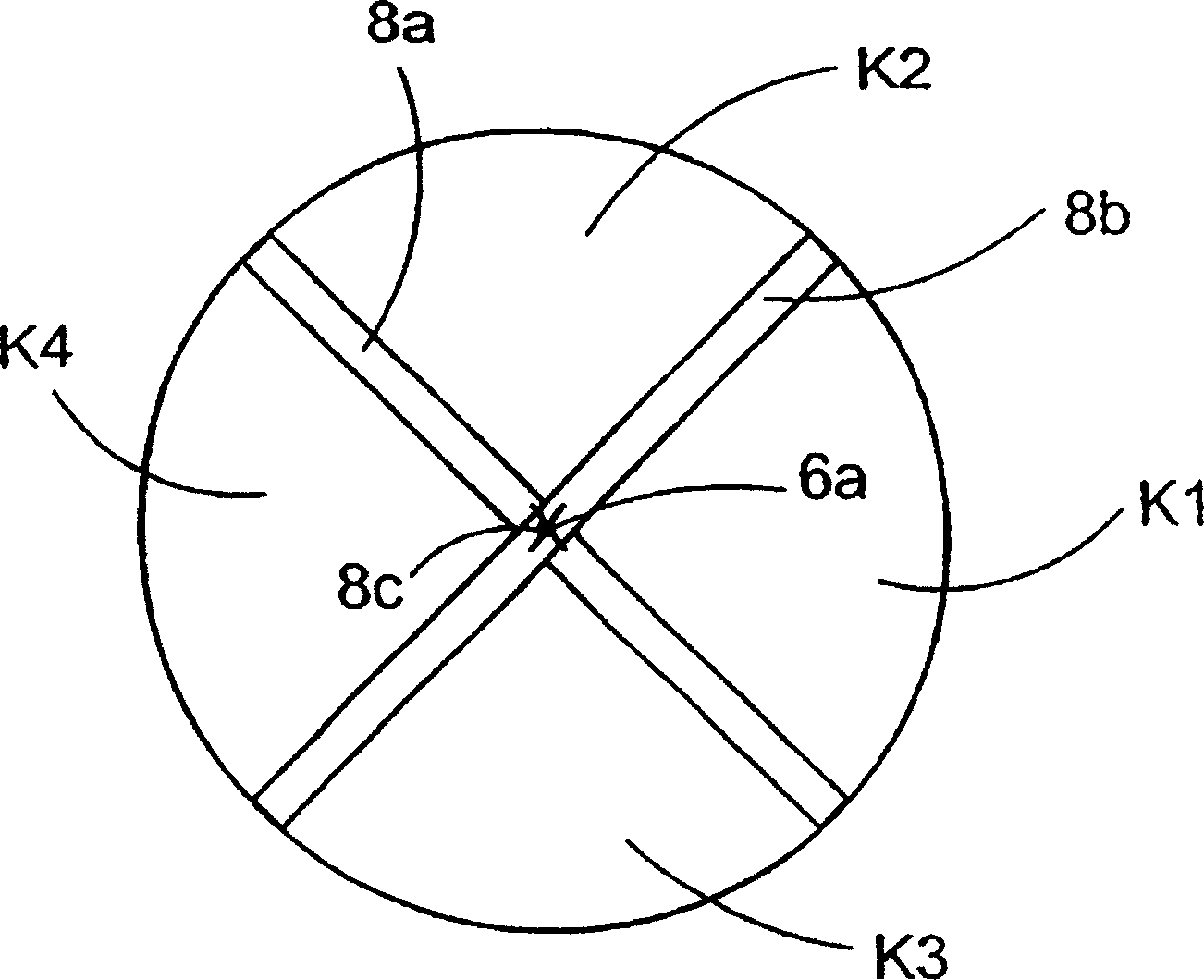

[0014] According to the invention, at least one pair of intersecting walls 8a, 8b (see Figure 2a ) and 9a, 9b and 10a, 10b (see FIG. 3a) are set in the channel 6. as from Figure 2a and 4 As seen, we will now first refer to the Figure 2a , 2b and 4 detail the construction of a pair of walls arranged like a cross i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com