Group manage system for elevator

A group management and elevator technology, applied in elevators, transportation and packaging, etc., can solve the problems of elevator group management system service reduction and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

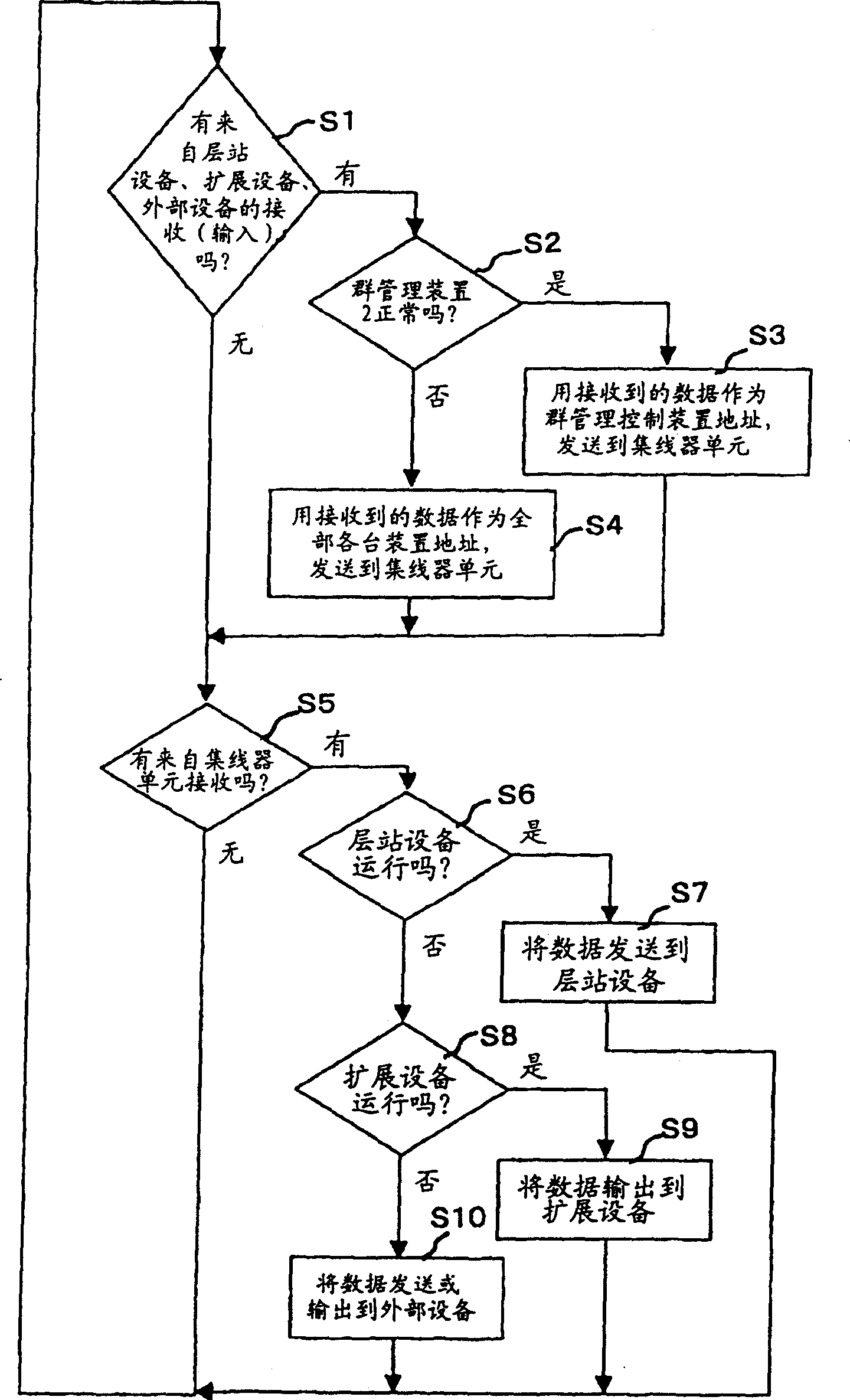

[0025] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

[0026] Implementation form

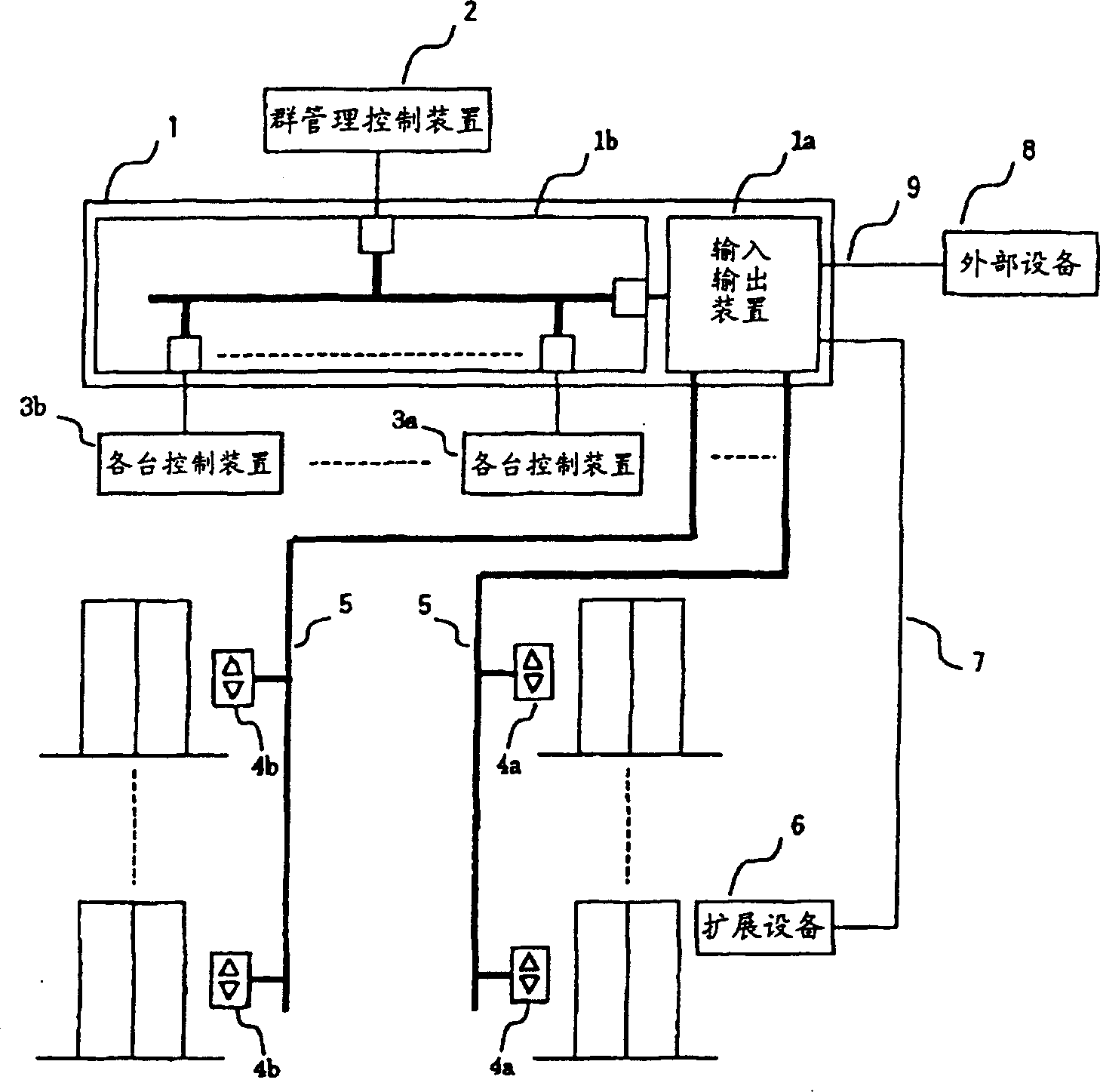

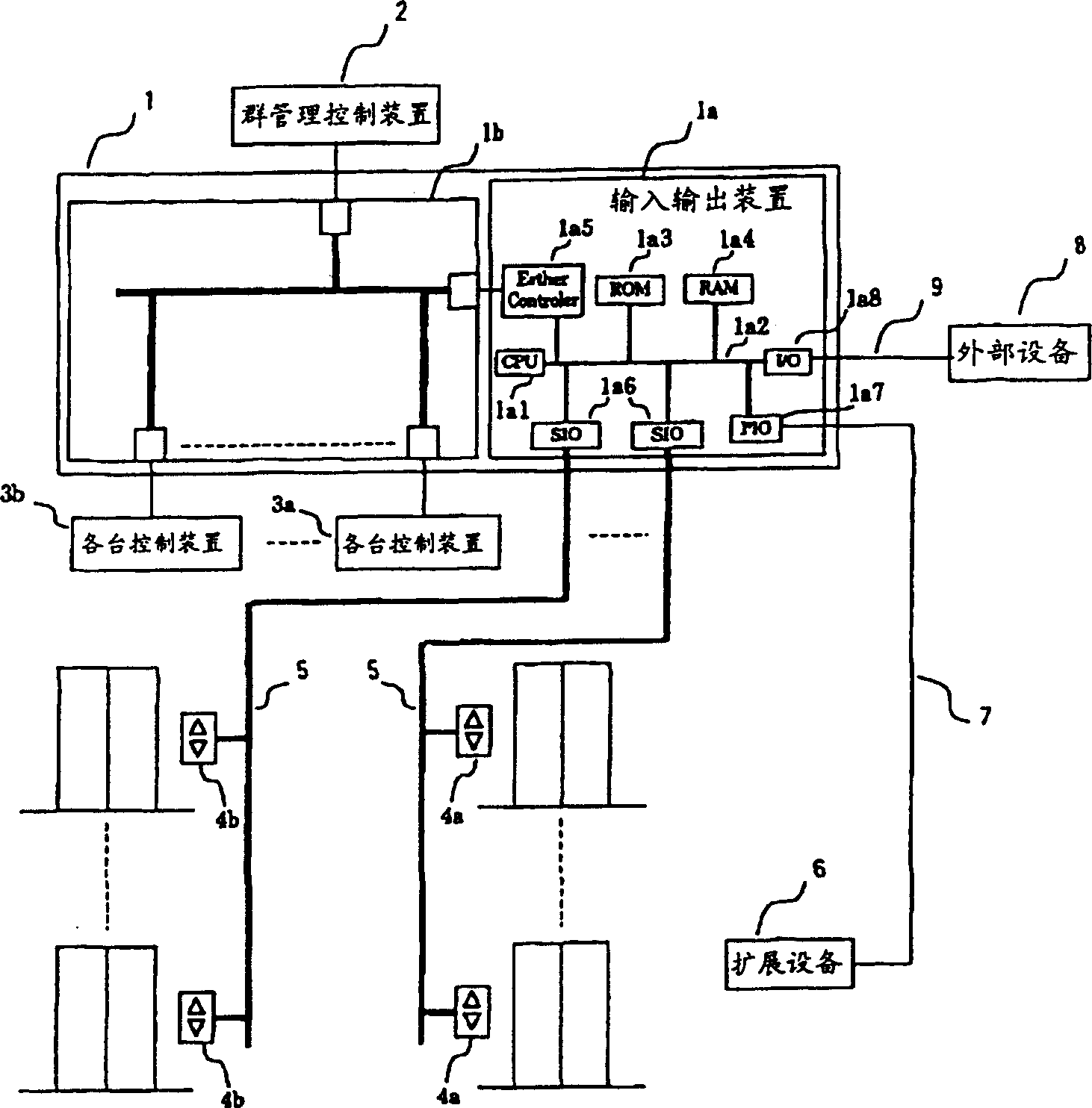

[0027] figure 1 A block diagram showing the configuration of the elevator group management system according to the embodiment of the present invention.

[0028] exist figure 1 Among them, 1 is a built-in hub of the input / output device installed between the group management device 2 that performs group management control on a plurality of elevators and each control device 3 (generally referred to as 3a and 3b ) that controls each car of the elevator. , including input and output devices 1a and hub 1b. 4 (collective term of 4a, 4b) is the hall equipment such as the call button installed in the hall, 5 is the hall serial communication line connecting the hall equipment 4 and the input / output device 1a, and 6 is not connected with the hall serial communication line. The communication line 5 is connected to the expansion equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com