Steel cable lifting belt driving wheel for oil production machine

A technology of lifting belt and driving wheel, which is applied in the direction of machine/engine, mining fluid, earthwork drilling, etc., can solve the problems of high loss and labor intensity, excessive wear of steel cable belt, friction load, inertial load, vibration load increase, etc. , to reduce oil production energy consumption, improve oil production efficiency, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

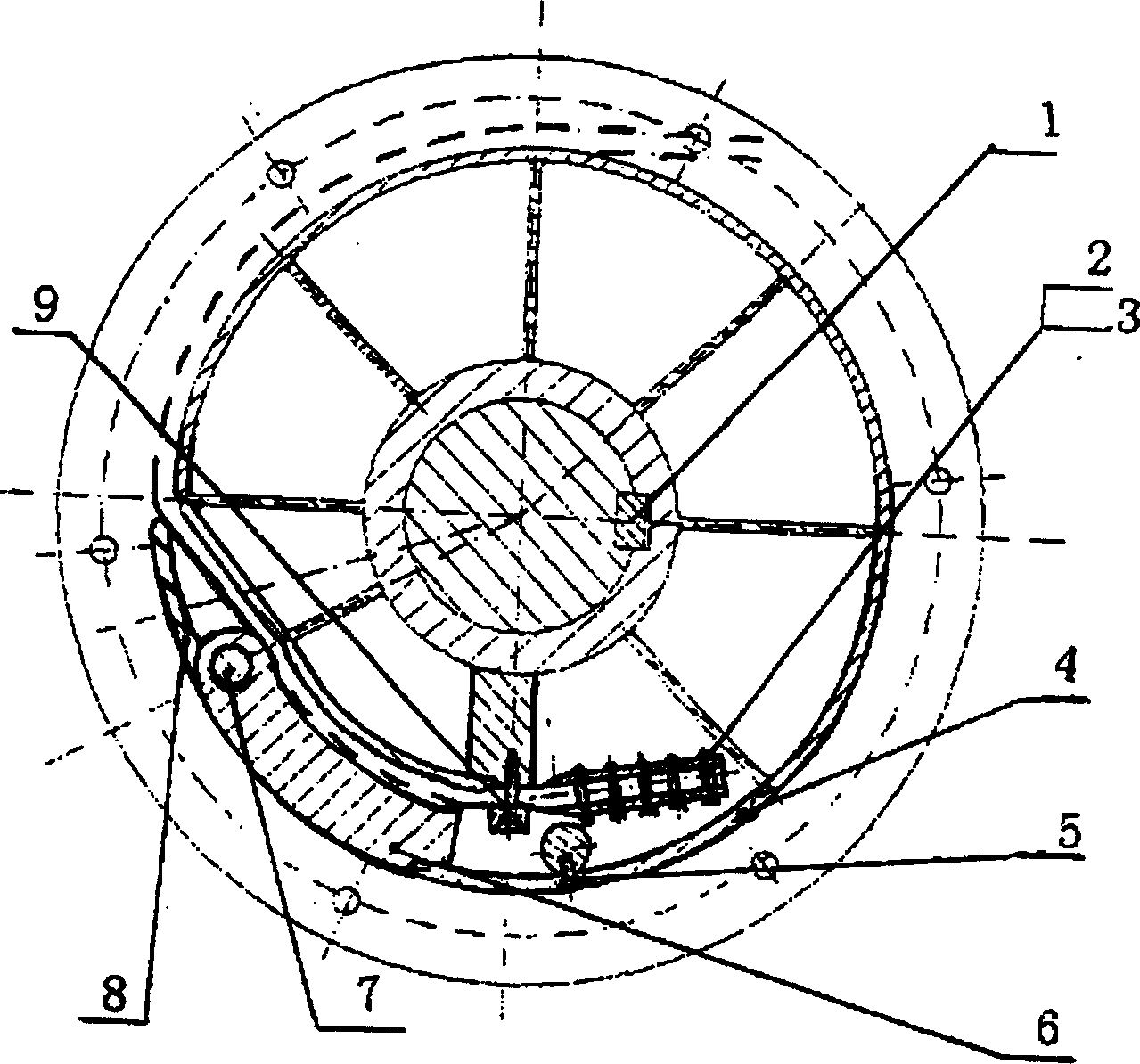

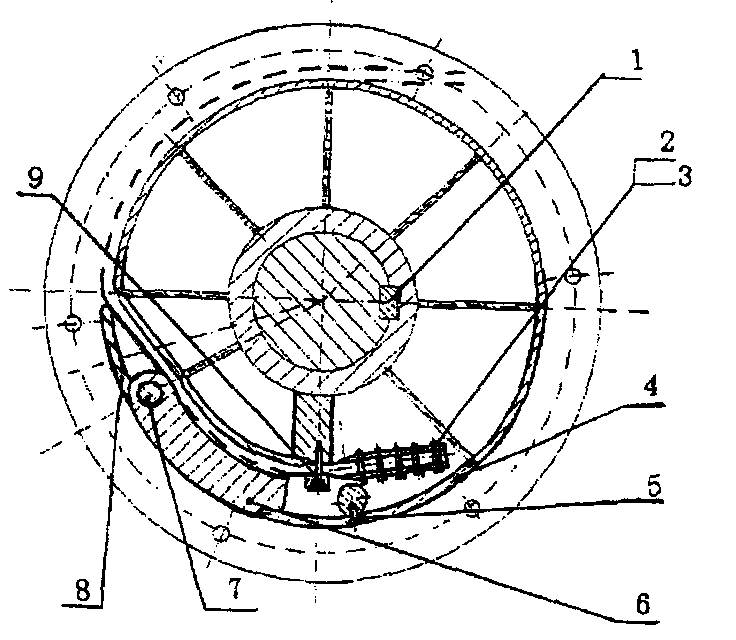

[0007] Concrete structure of the present invention can refer to accompanying drawing: among the figure, drive wheel excircle is designed into an involute type, progressive circle wheel diameter 600mm-1200mm, progressive difference is 0-360 °=steel cable hoist belt thickness. The thickness of the steel cable lifting belt is 6mm-60mm. The arc-shaped pressing plate 4 of the downward 90° position at the drive wheel steel cable hoisting belt outlet is designed as a structure that can be fixed and disassembled with bolts. One end of the arc-shaped pressing plate 4 is crimped to the rotating pressing plate 6, the rotating pressing plates 6, 8 are coaxially hinged on the shaft 7, and the movable end of the rotating pressing plate 8 is the outlet of the steel cable lifting belt. The inside of the driving hub is designed in the form of locking the steel cable hoist belt with fixing bolts. The specific embodiment of above-mentioned structure sees figure 1 One end of the steel cable hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com