Method for changing connecting component part of steps escalator and apparatus for guiding it out of rail

A technology of escalator and guide rail device, which is applied in escalator, transportation and packaging, etc. It can solve the problems of difficulty in replacing step connectors, long time required, and the replacement operation cannot be performed by 2 to 3 people at the same time, so as to shorten The effect of changing the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

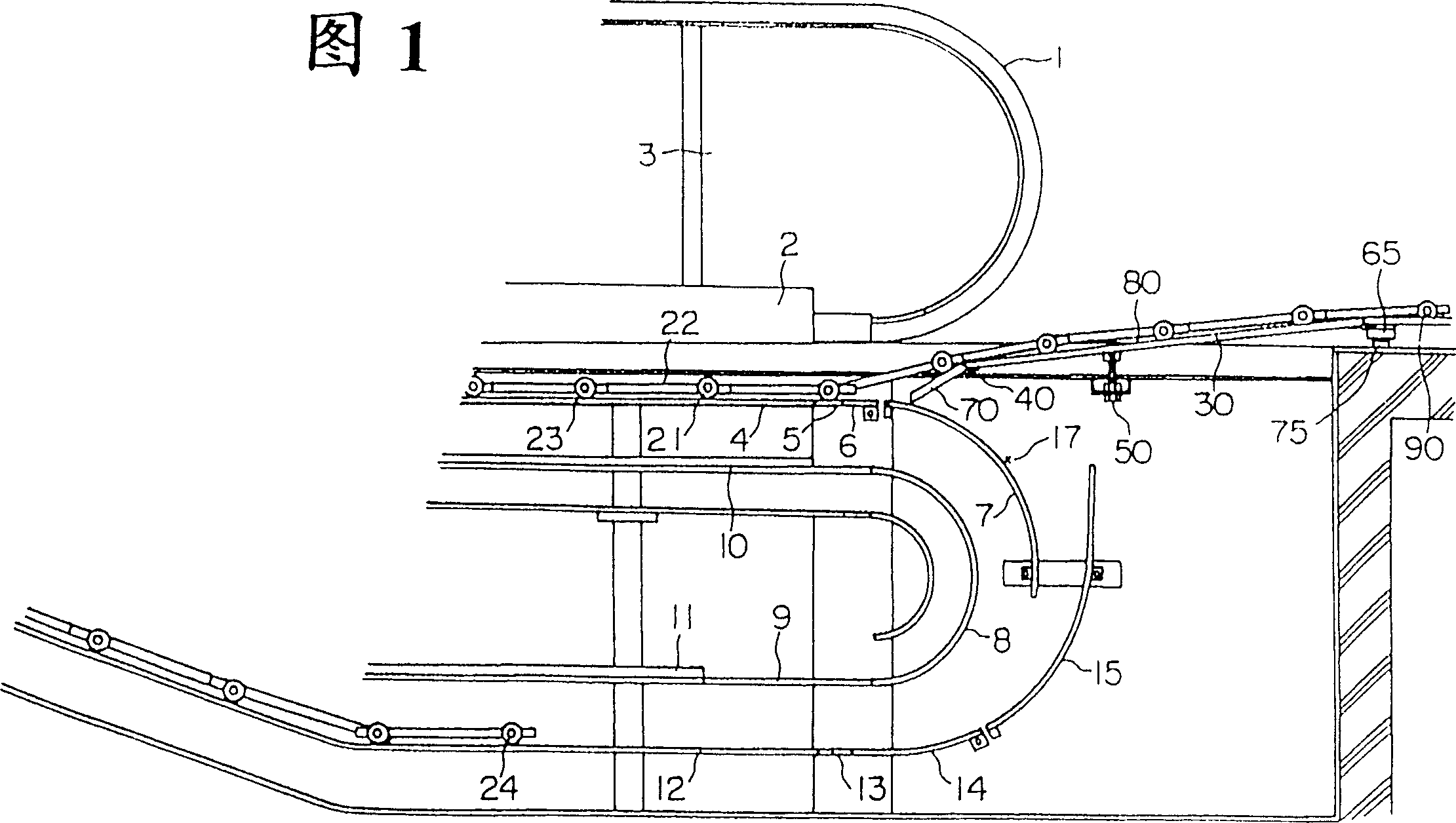

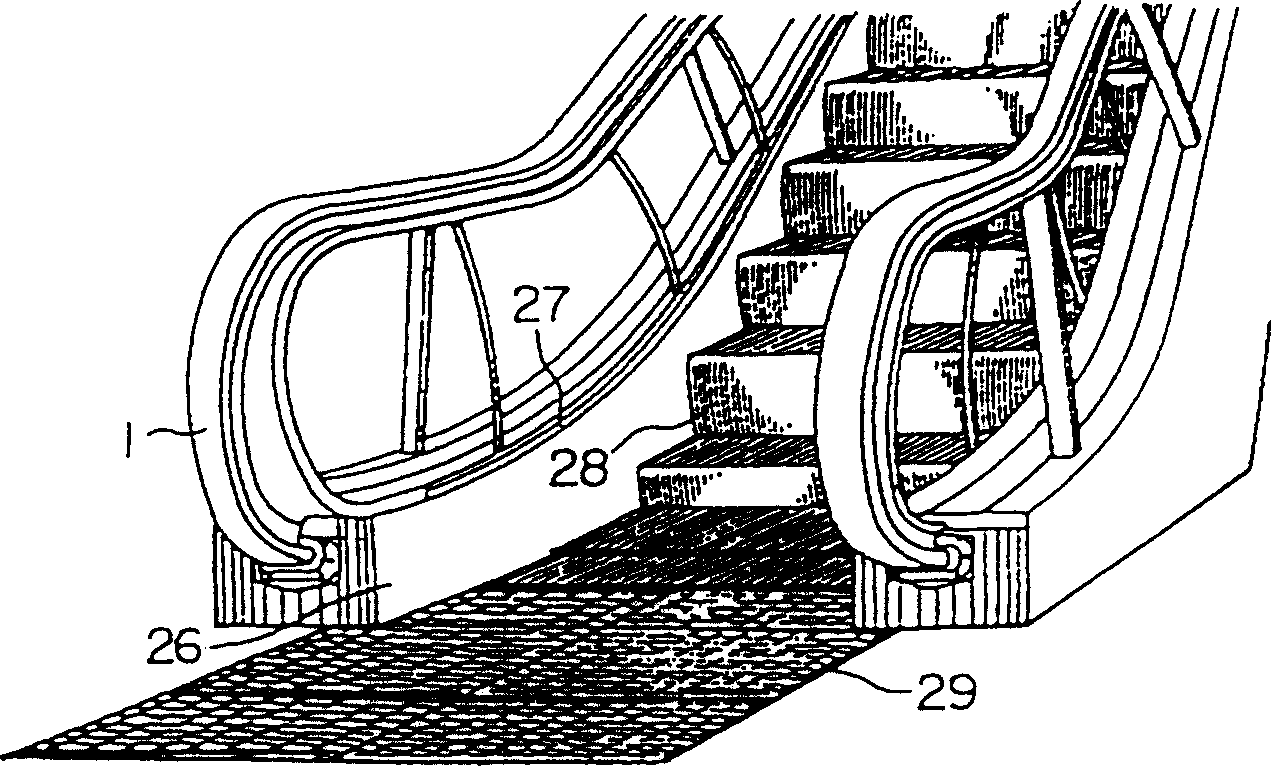

[0043] Describe the embodiment of the present invention below with reference to Fig. 1, Fig. 1 is the cross-sectional view of the step connector replacement method of the escalator of the embodiment of the present invention, and Fig. 19 identical or corresponding part is represented with identical symbol, and its description is omitted.

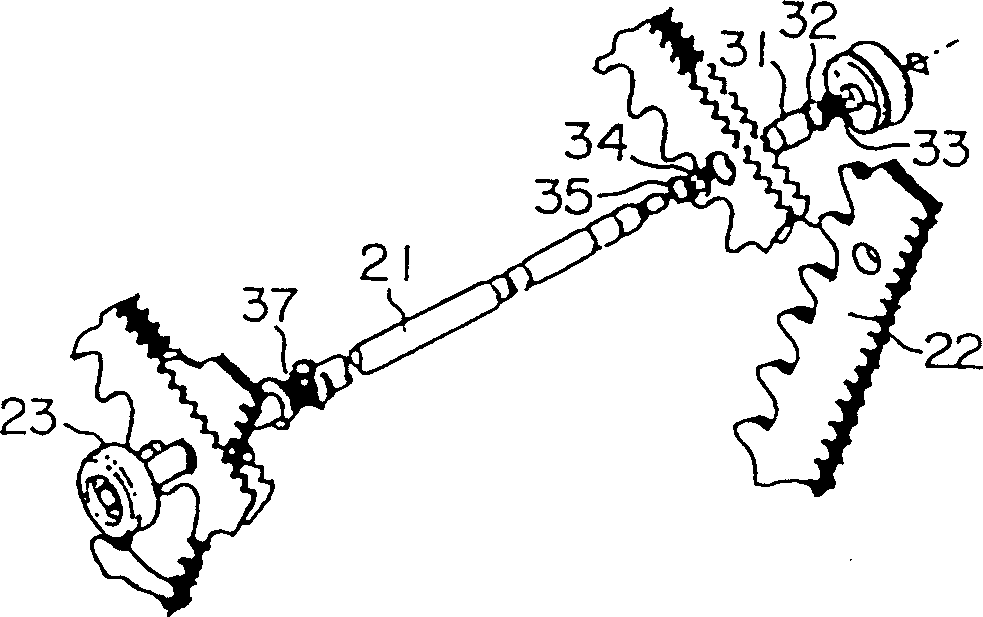

[0044] In Fig. 1, the lead-out guide rail device 30 is used to carry the step wheels 23 on the left and right sides above, and the step connector 22 is drawn to the device at the place where the ladder is taken, and two left-right symmetrical guide rails are arranged in parallel. Each lead-out rail device 30 such as Figure 4 As shown, it is composed of three kinds of guide rail parts such as a first guide rail (wheel support portion) 70 , a second guide rail (lead-out rail) 80 , and a holding rail 90 . The guide rail extends from the mechanical room to the ground of the building, and one end is disassembled and connected, and is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com