Modularized testing device and testing equipment applied by modularized testing device

A testing device and modularized technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of cumbersome and time-consuming replacement operations, increase the volume of the test device 14A, increase the operation time, etc. The effect of automatic timing, reduction of replacement operation time, and improvement of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

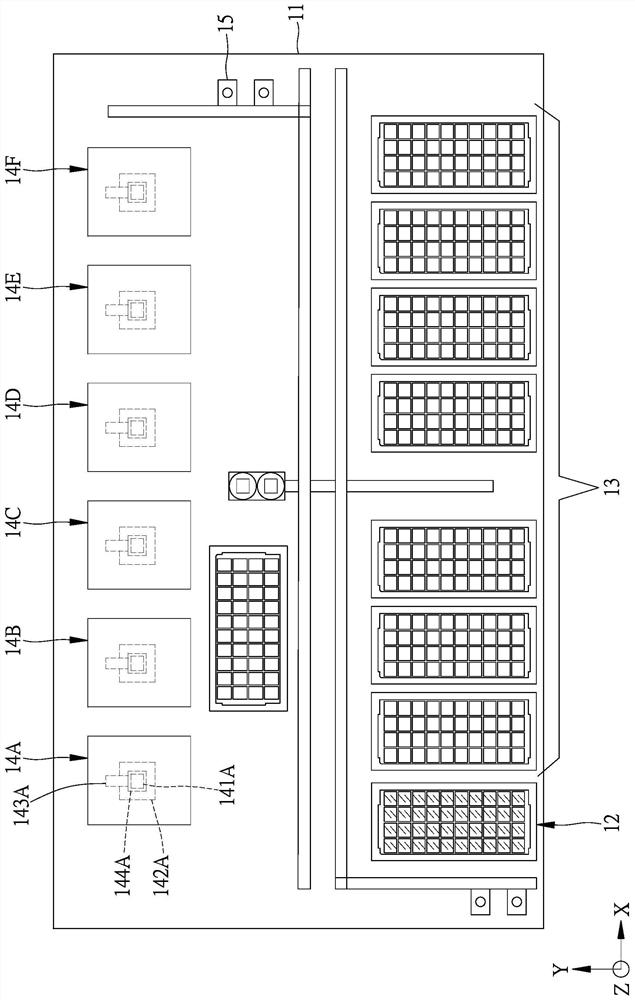

[0050] In order to make the present invention be further understood, hereby give a preferred embodiment and cooperate drawing, describe in detail as follows:

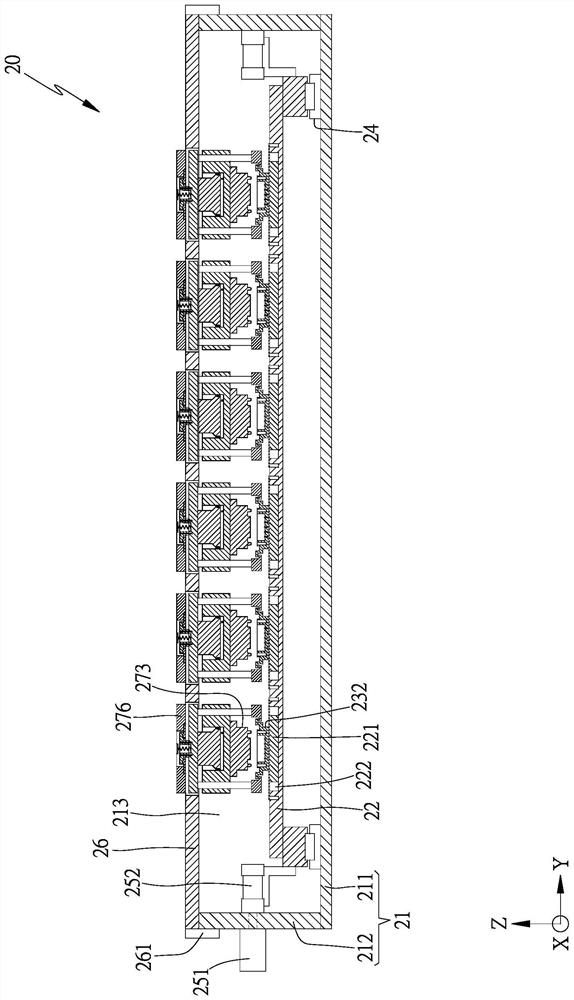

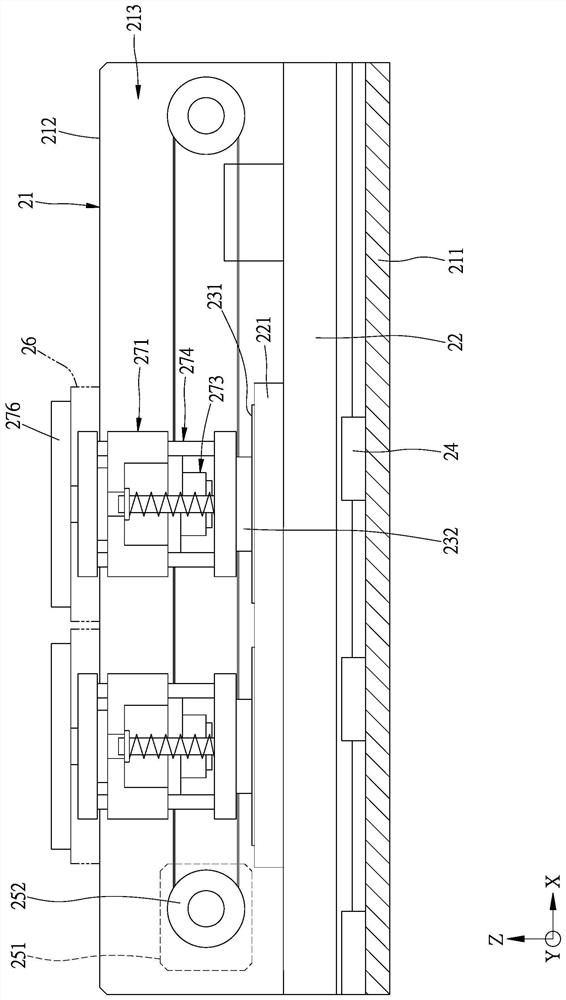

[0051] see Figure 2 to Figure 5 , the modular testing device 20 of the present invention includes a receiving unit, a testing unit and a crimping unit, and may also include a driving unit to automatically drive the testing unit to move into / out of the receiving unit depending on the operation requirements.

[0052] The supporting unit is provided with at least one carrier 21. The carrier 21 can be a panel, a frame or a box, and its type can be a flat or ㄩ type. The carrier 21 only needs to carry the test unit, the crimping unit and the driver. The unit is not limited to this embodiment; in this embodiment, the carrier 21 includes a bottom plate 211 and two side plates 212, the two side plates 212 are fixed on the bottom plate 21 in the Z direction, and a gap is formed between the bottom plate 211 and the two side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com