Elastomer drum of line printer

A printer and elastomer technology, applied in the field of printing, can solve the problems of excessive compression coefficient and excessive wear of the roll, achieve the effect of large compression fatigue strength and increase the printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

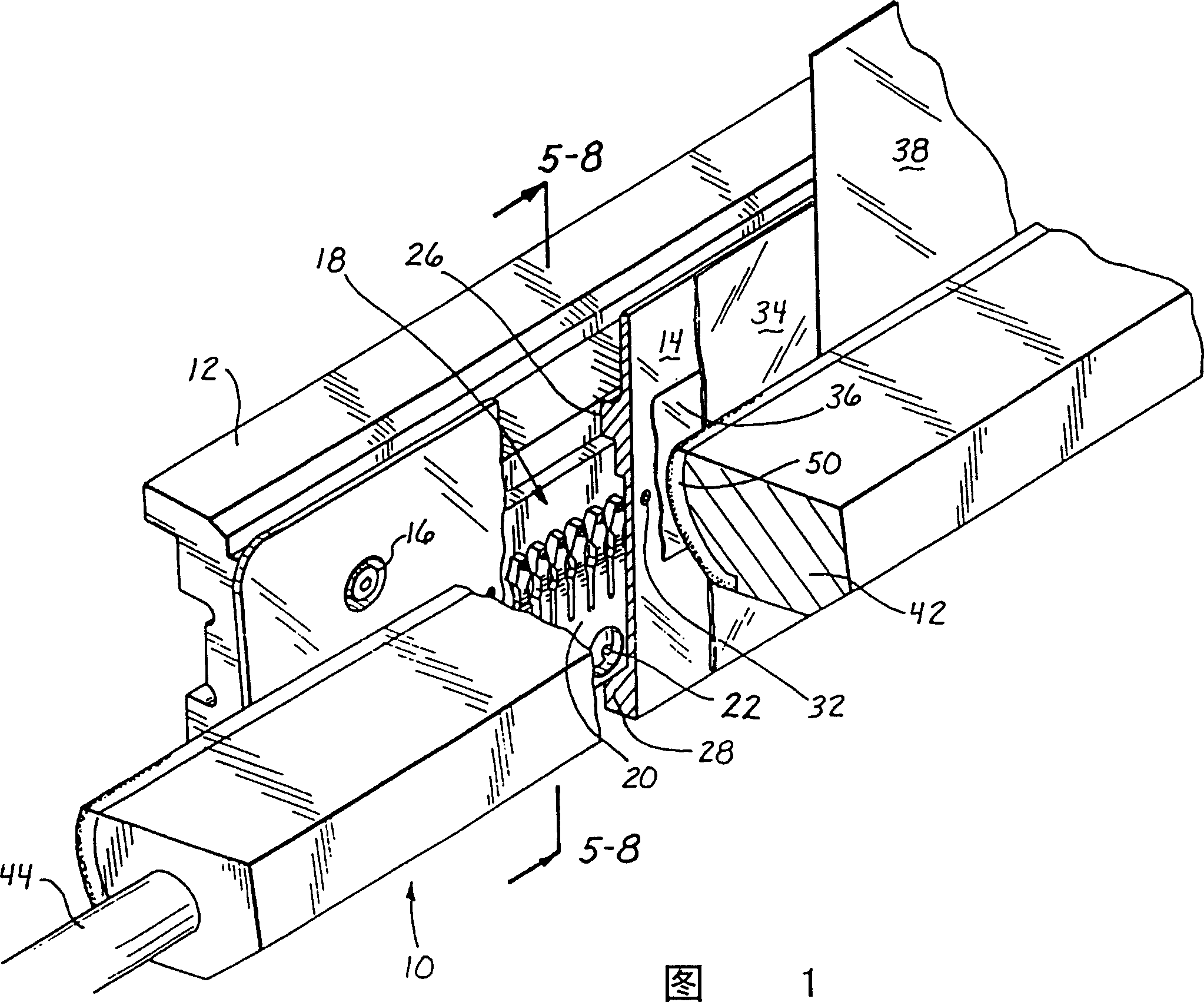

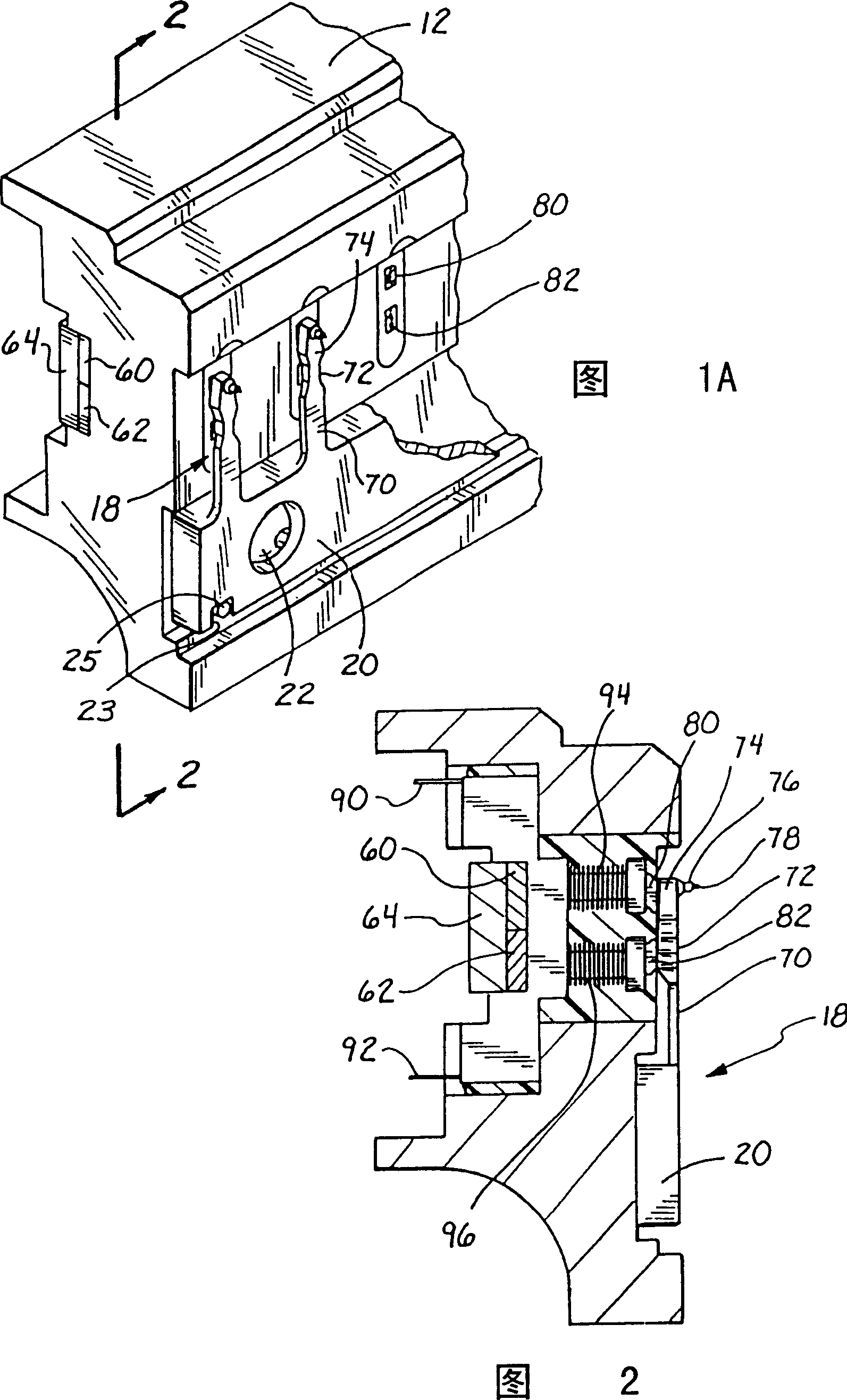

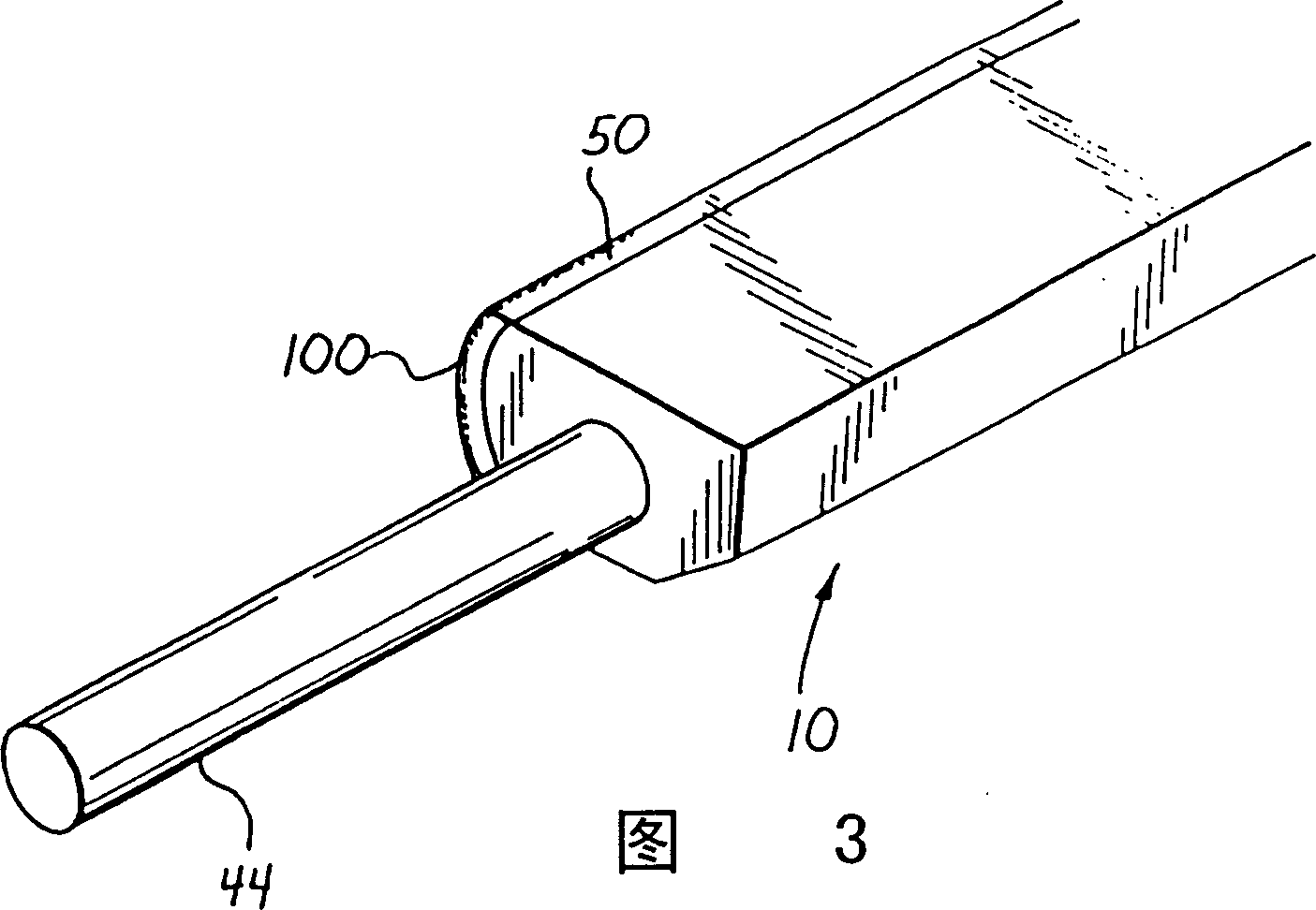

[0027] Figure 1 shows a partial cross-sectional general view of a roll of elastic backing paper, as well as a print hammer set and related devices. Referring specifically to Figure 1, it can be seen that the mandrel 10 is shown in section. The spool 10 is in substantially longitudinal relationship with a print hammer stack 12 . The print hammer set 12 has a cover 14 thereon which has been secured to the print hammer set with a plurality of threaded components such as screws, bolts or other securing means 16 .

[0028] The printing hammer group 12 can have a plurality of printing hammers 18, and they are all formed on a positioning plate 20, which is fixed to the printing hammer group by threaded fasteners such as screws or bolts 22, and is generally shown in Figure 1A. Orientation of notches 23 and pins 25 pin and notch orientation. Each print hammer 18 can be seen more closely with a print head which will be exemplified below.

[0029] The cover 14 has longitudinal upper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com