Device for implanting lens into eye

A technology for embedding devices and lenses, which can be used in intraocular lenses, eye implants, prostheses, etc., and can solve problems such as difficult orientation and unexpectable vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

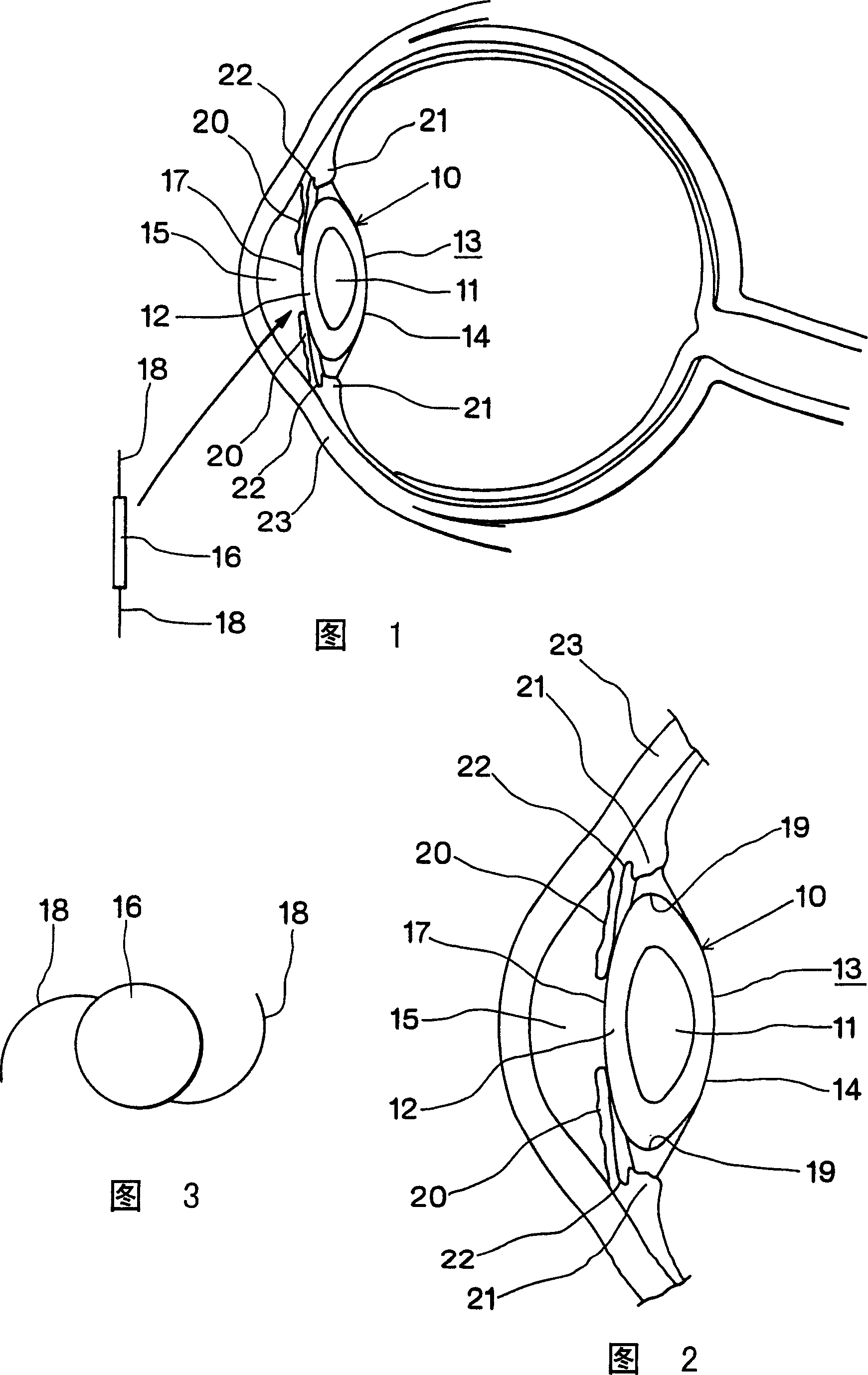

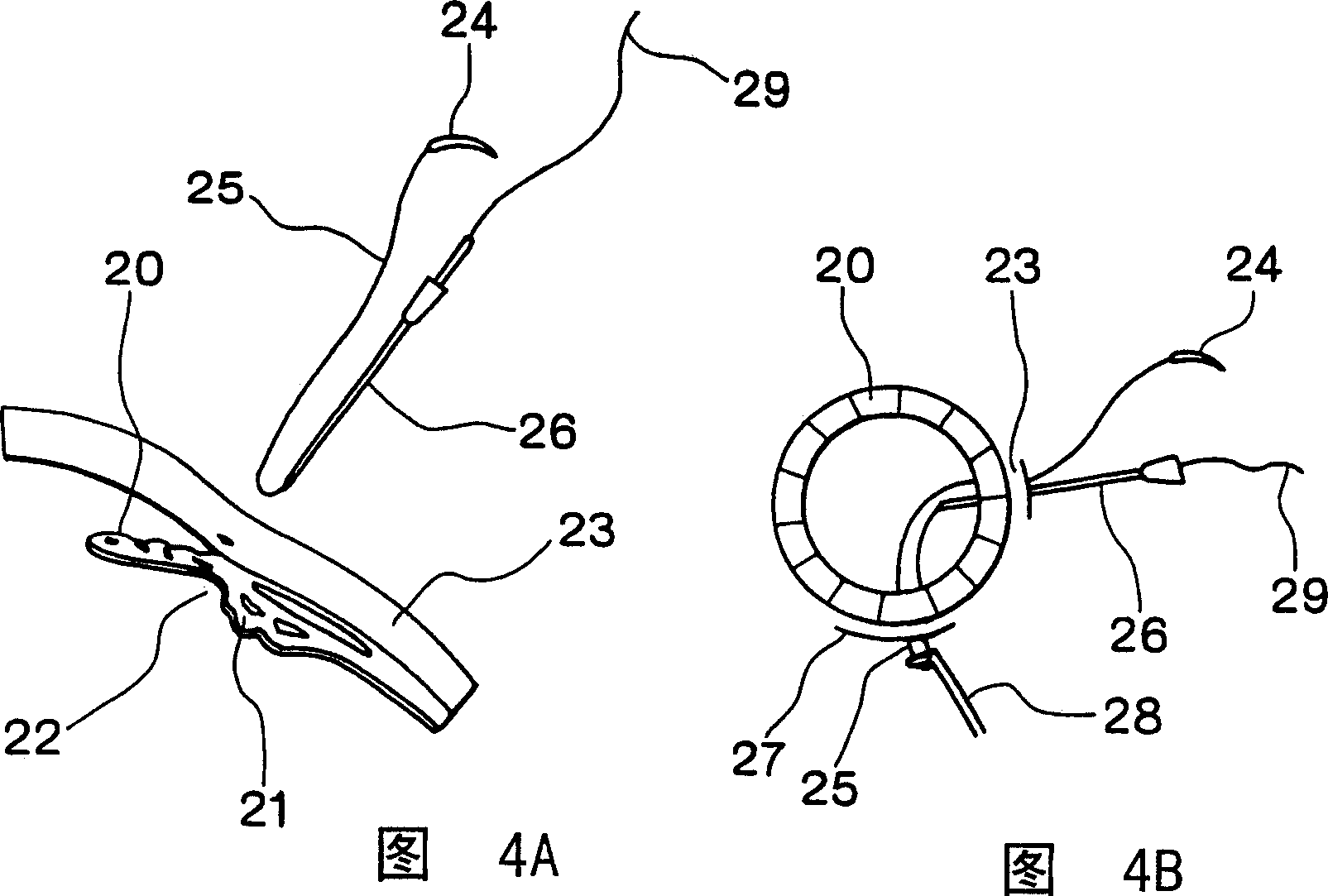

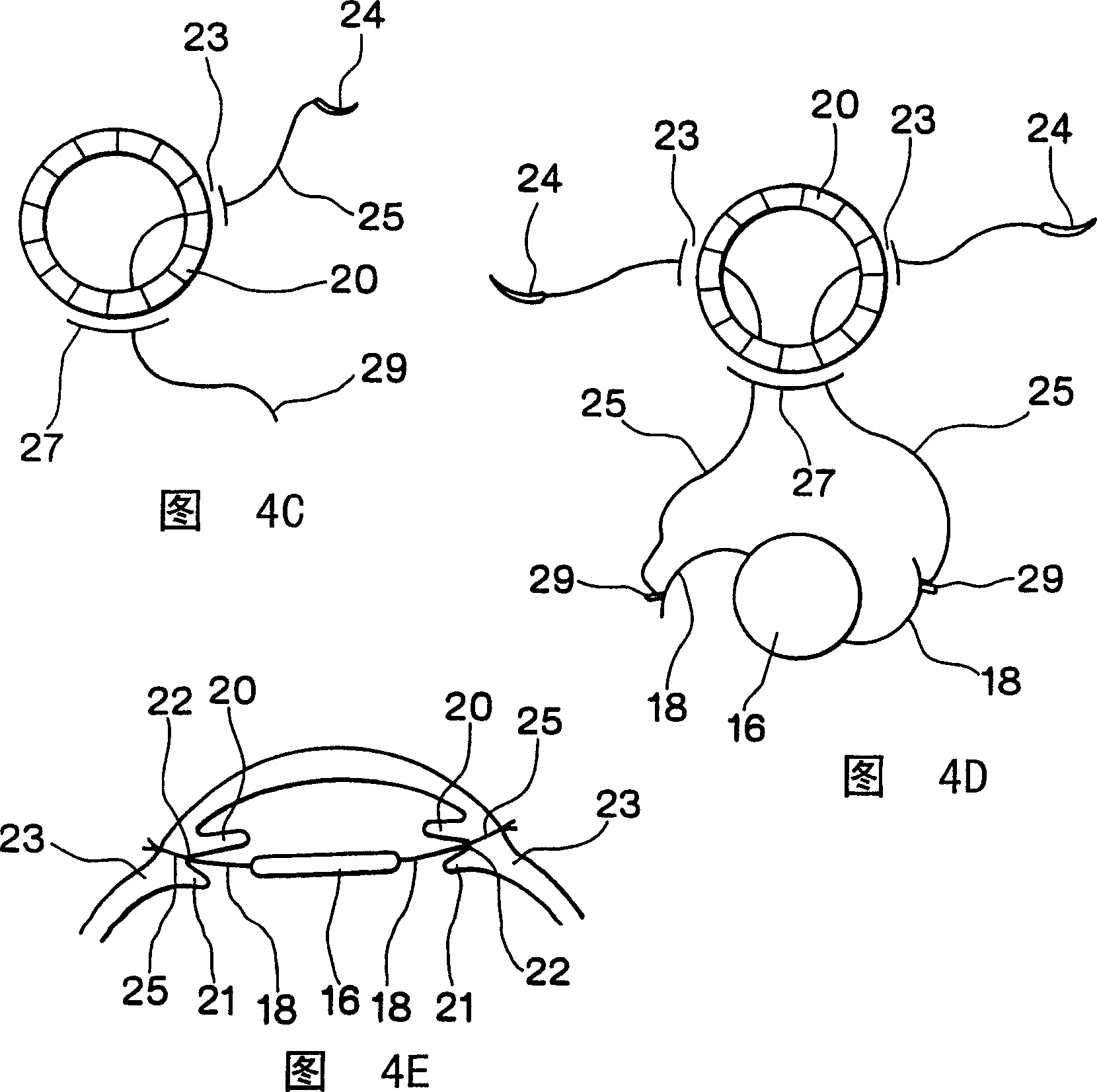

[0022] Embodiments of the present invention will be described below with reference to the accompanying drawings. As shown in Figures 6 to 8, the intraocular lens embedding device of the present invention is composed of a spacer 50 and a lead wire 51. The spacer 50 is formed by an elastic body that is harmless to the human body such as silicon rubber or silicon sponge. The back of the spacer 50. The insertion device described above is used when the posterior lens 16 is attached to the portion supporting the posterior chamber lens 16 , that is, the eyeball without the phakic capsule 13 .

[0023] Viewed from a plane, the gasket 50 is basically fan-shaped. As shown in FIG. 7 , the top surface 52 of the gasket 50 is basically a flat surface. A front inclined surface 53' of the bottom surface 53 of the spacer 50 is inclined toward the top surface 52, and a tapered insertion portion 54 is formed here. The spacer 50 has a thickness of 1.0 to 2.0 mm at the thickest middle portion. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com