Driving method of plasma display panel of alternating current for creation of gray level gradations

A plasma and display panel technology, applied in the plasma field, can solve the problem that the image frame cannot exceed 78.8%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, various embodiments of the present invention will be described in detail with reference to the accompanying drawings.

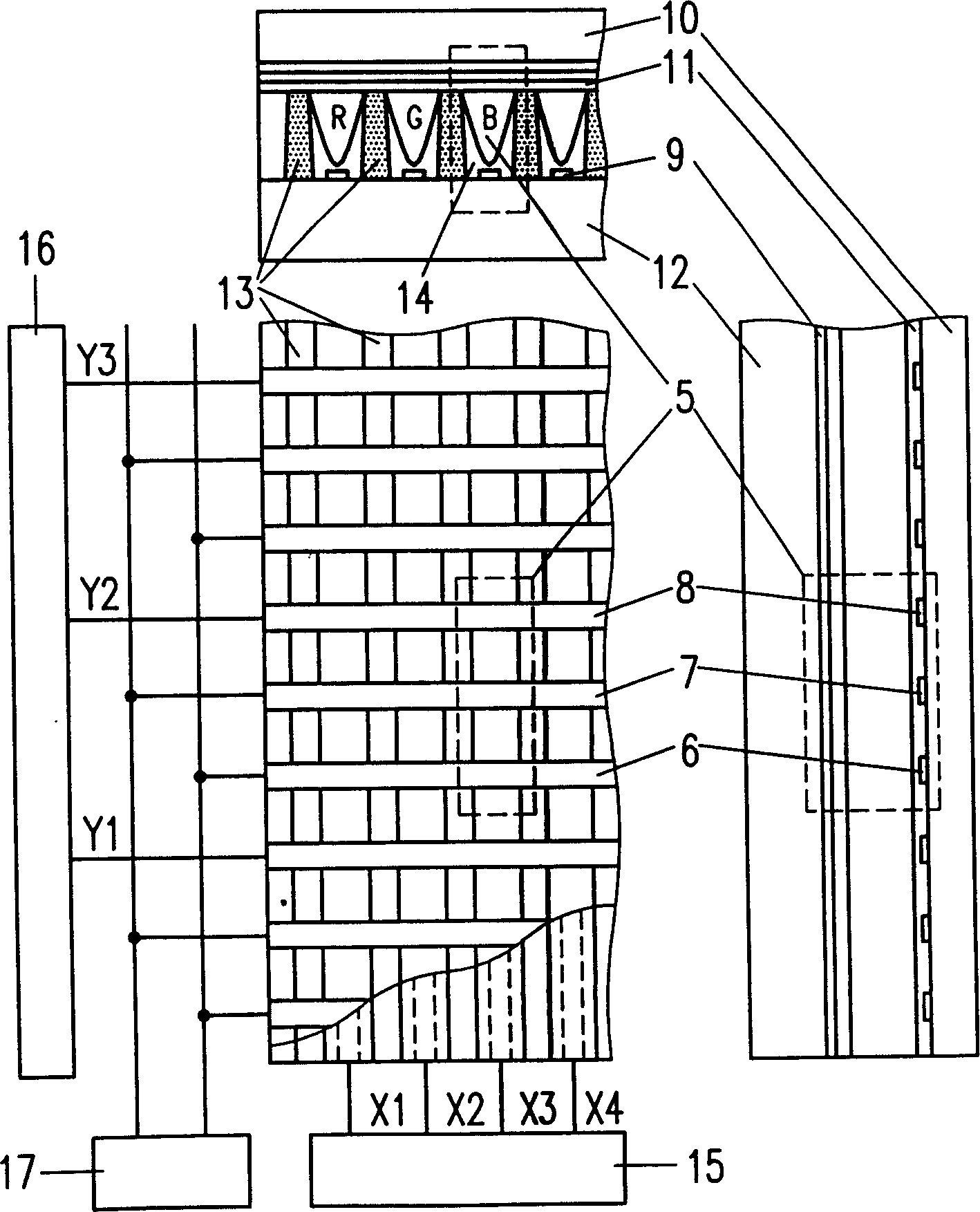

[0037] refer to figure 1 , which is a schematic structural diagram of an AC-type PDP driving device for gray scale display according to the present invention. figure 1 In each pixel 5, each pixel 5 includes: a first display electrode 6 and a second display electrode 7 placed parallel to each other; a scan electrode 8 located close to the second display electrode 7; 7 and scan electrodes 8 intersect with data electrodes 9 perpendicular to each other. The first and second display electrodes 6 and 7 and the scan electrodes 8 are formed under the upper glass plate 10 and covered with an insulating film 11 . The data electrode 9 is placed between the spacers 13 on the lower glass plate 12, and is perpendicular to the first and second display electrodes 6 and 7 placed on the upper glass plate 10, while being covered with red (R), green Three fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com