Plasma display

A plasma and display technology, used in static indicators, instruments, cold cathode tubes, etc., can solve the problems of thin design that cannot be used with PDP displays, and the large size of rupture detection sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

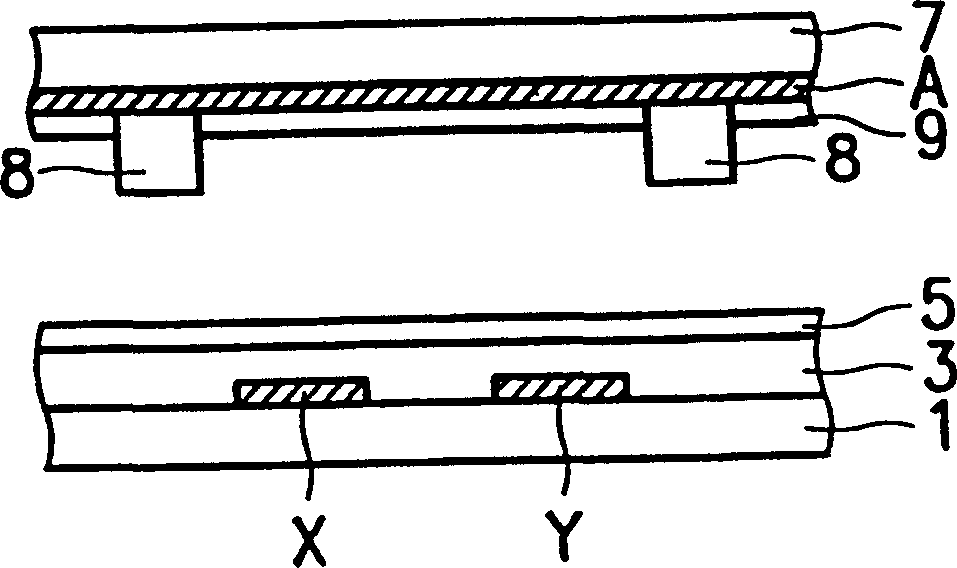

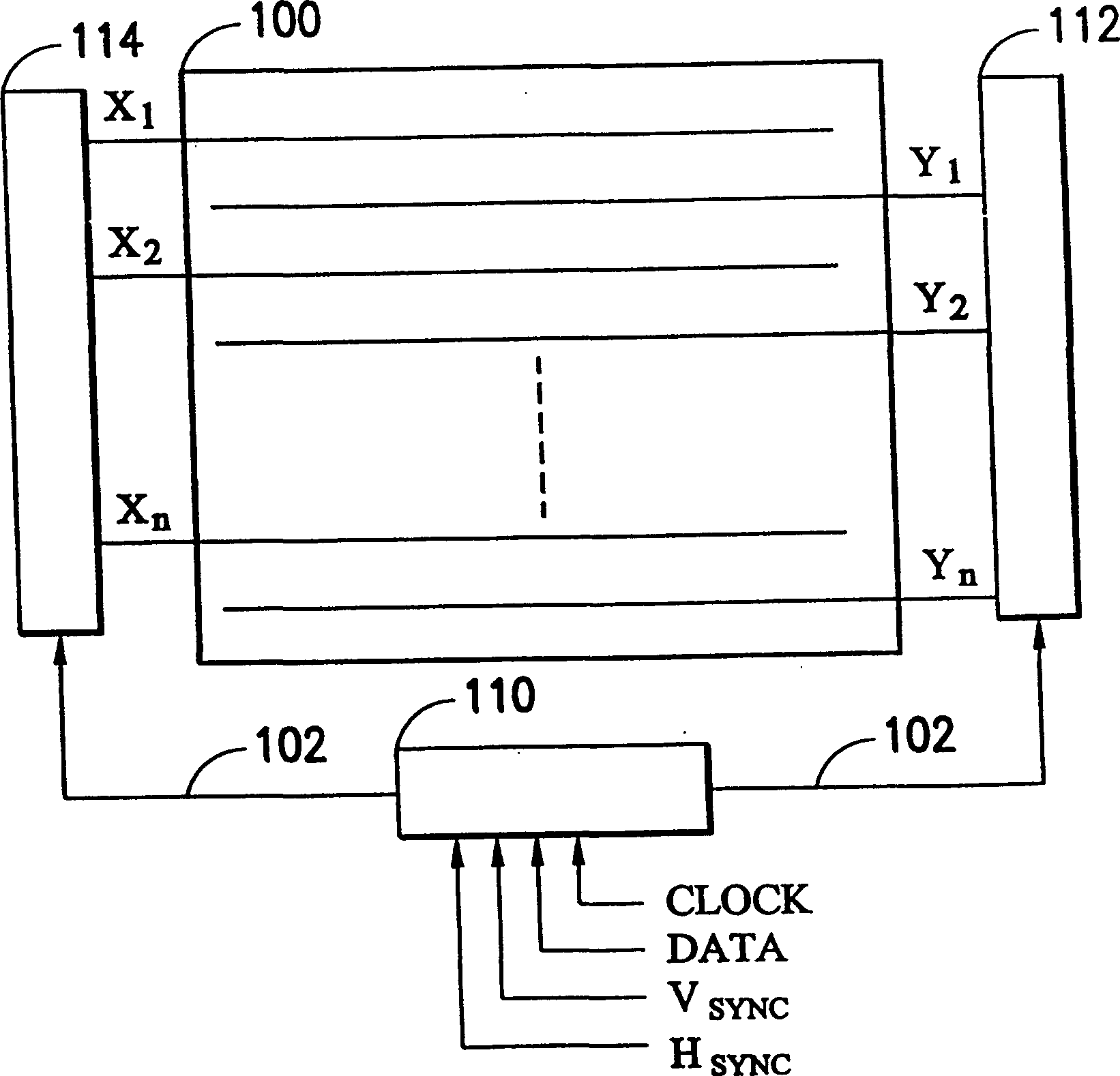

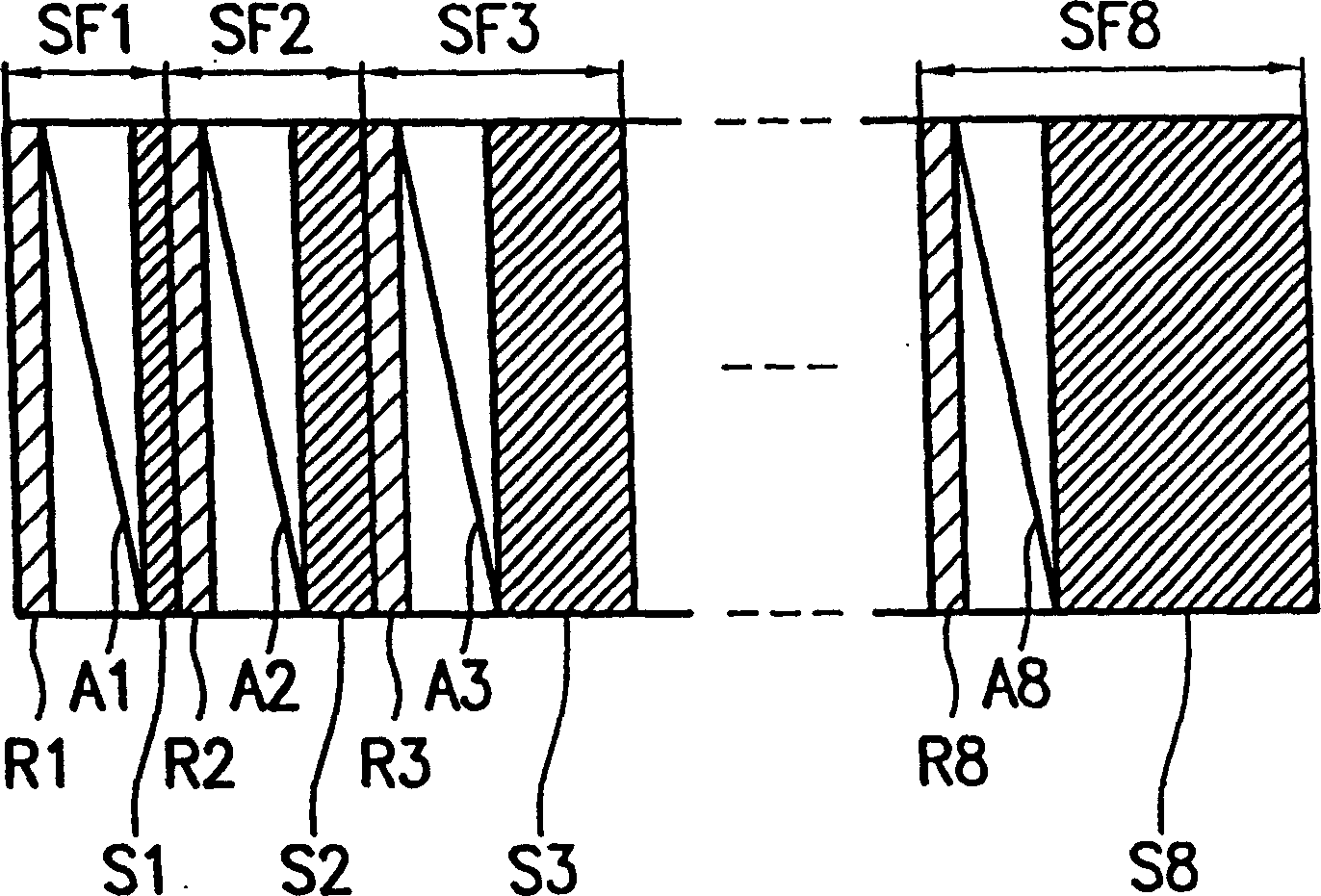

[0024] reference Figure 5 versus Figure 8 , Figure 5 This is a schematic diagram of a plasma display in this embodiment; Figure 8 This is a schematic cross-sectional view of the display unit 10 in the plasma display (PDP) of this embodiment.

[0025] Such as Figure 8 As shown, the plasma display is composed of a front substrate 1'and a rear substrate 7'. The front plate 1'includes scan electrodes Y'and sustain electrodes X'parallel to each other, a detection wire L1, a dielectric layer 3', and a protective film 5'. The rear plate 7'includes address electrodes A', partition walls 8'(partition walls) on both sides of the address electrodes, and fluorescent materials 9'between the barrier walls 8'. The plasma display includes a plurality of pixels 10. When a bias voltage is applied between the sustain electrode X'and the scan electrode Y', the pixels 10 can be discharged to make the plasma display display images.

[0026] reference Figure 5 , The front plate 1'of the plasma dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com