Series boosting solar cell unit and manufacturing method thereof

A technology of solar cells and anode electrodes, applied in the field of solar energy, can solve problems such as difficulty in adapting to the development needs of miniaturization, inability to integrate electronic circuits on a single chip, and large overall system volume, so as to reduce system volume and cost, and avoid booster devices , The effect of simplifying the power supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]If the micro solar cell compatible with the standard CMOS process is monolithically integrated with the micro power consumption system chip, the on-chip power supply can be realized, the system volume and cost can be reduced, and the integration and function of the system can be continuously improved to realize the real self-power supply SoC.

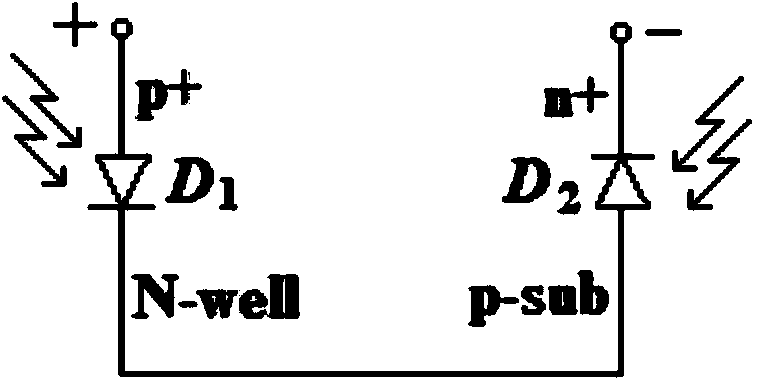

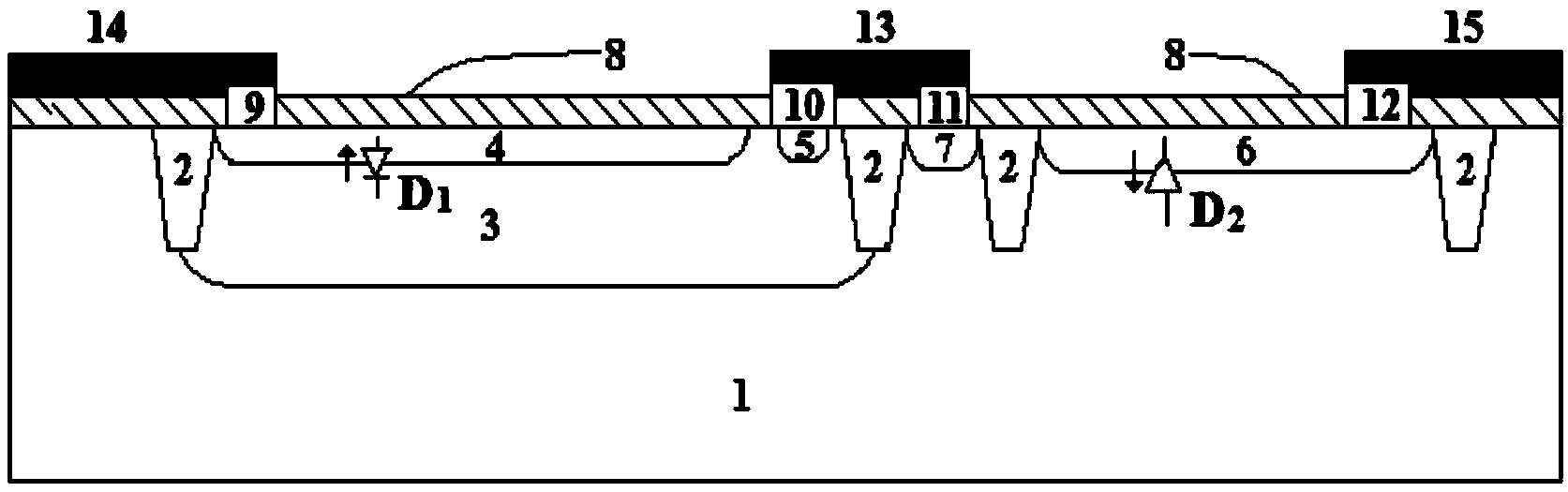

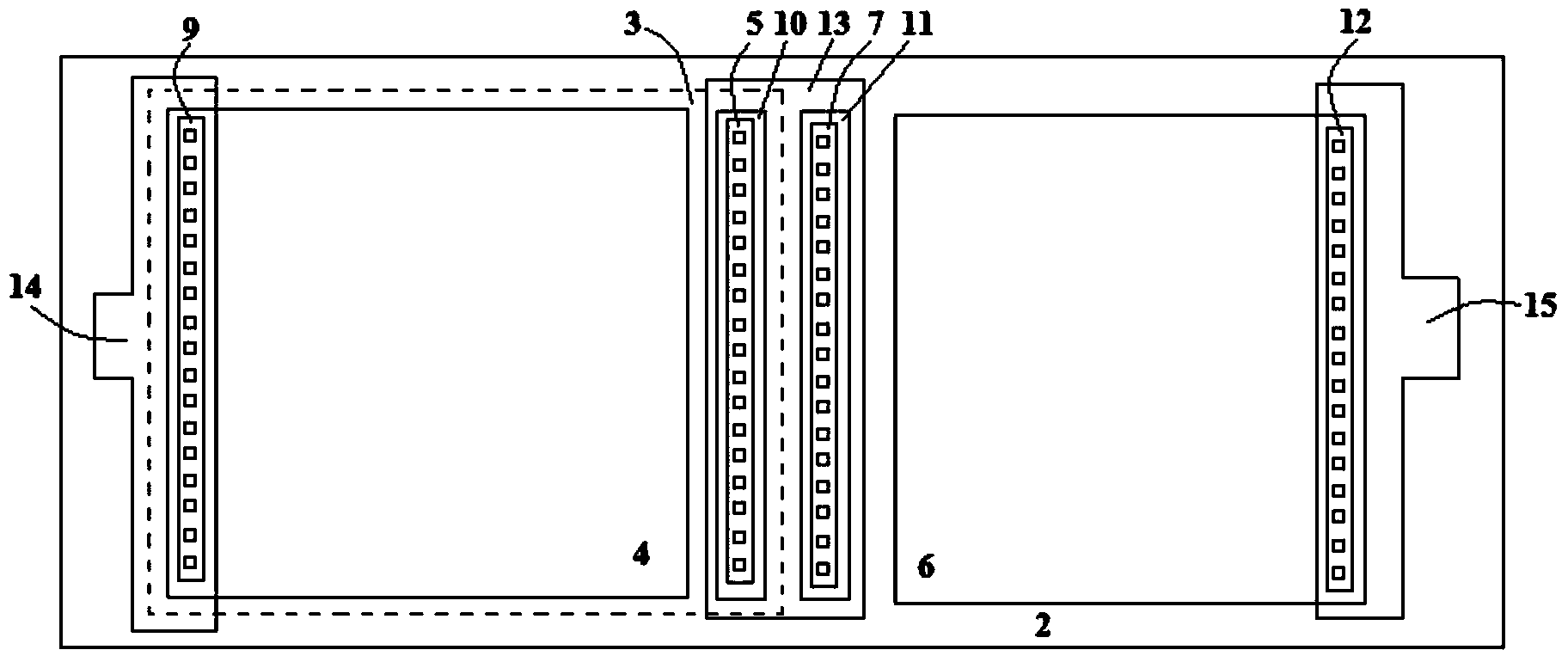

[0029] In order to overcome the unfavorable factors such as the large volume and high cost of conventional solar cells, and realize the automatic energy acquisition of micro-power system chips that work periodically such as radio frequency identification and wireless sensor network nodes, the present invention proposes an on-chip integrated system compatible with standard CMOS technology. A series boost solar cell unit, which is expected to directly drive low-voltage, micro-power electronic systems such as radio frequency identification and wireless sensor network nodes.

[0030] The series boost solar cell unit proposed by the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com