Fluidized bed boiler with multifunctional cyclone separator

A technology of fluidized bed boiler and cyclone separator, which is applied in the field of fluidized bed combustion equipment and fluidized bed boiler, which can solve the problems of increasing boiler power consumption and increasing furnace height, so as to improve combustion efficiency, reduce pollution emissions, and prolong high temperature The effect of the oxygen enrichment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

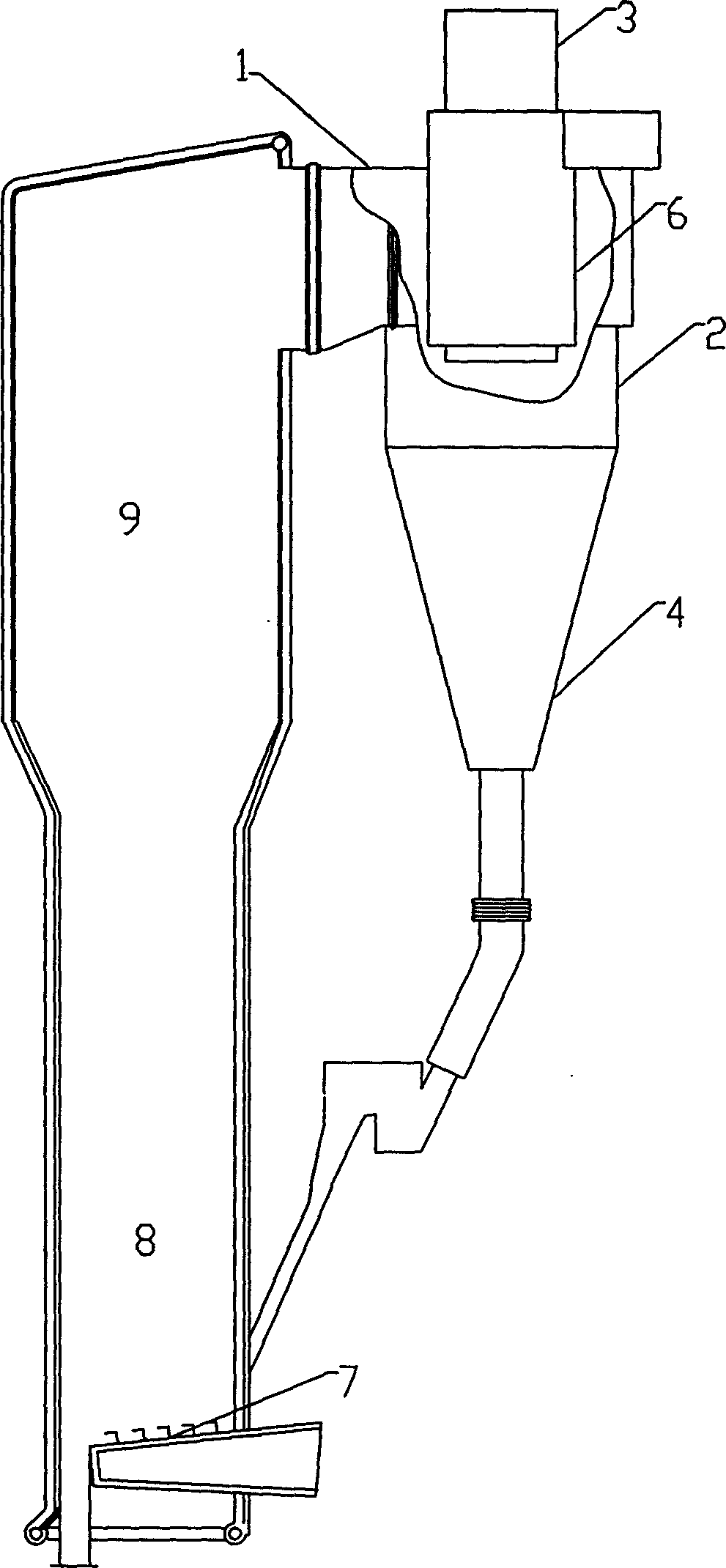

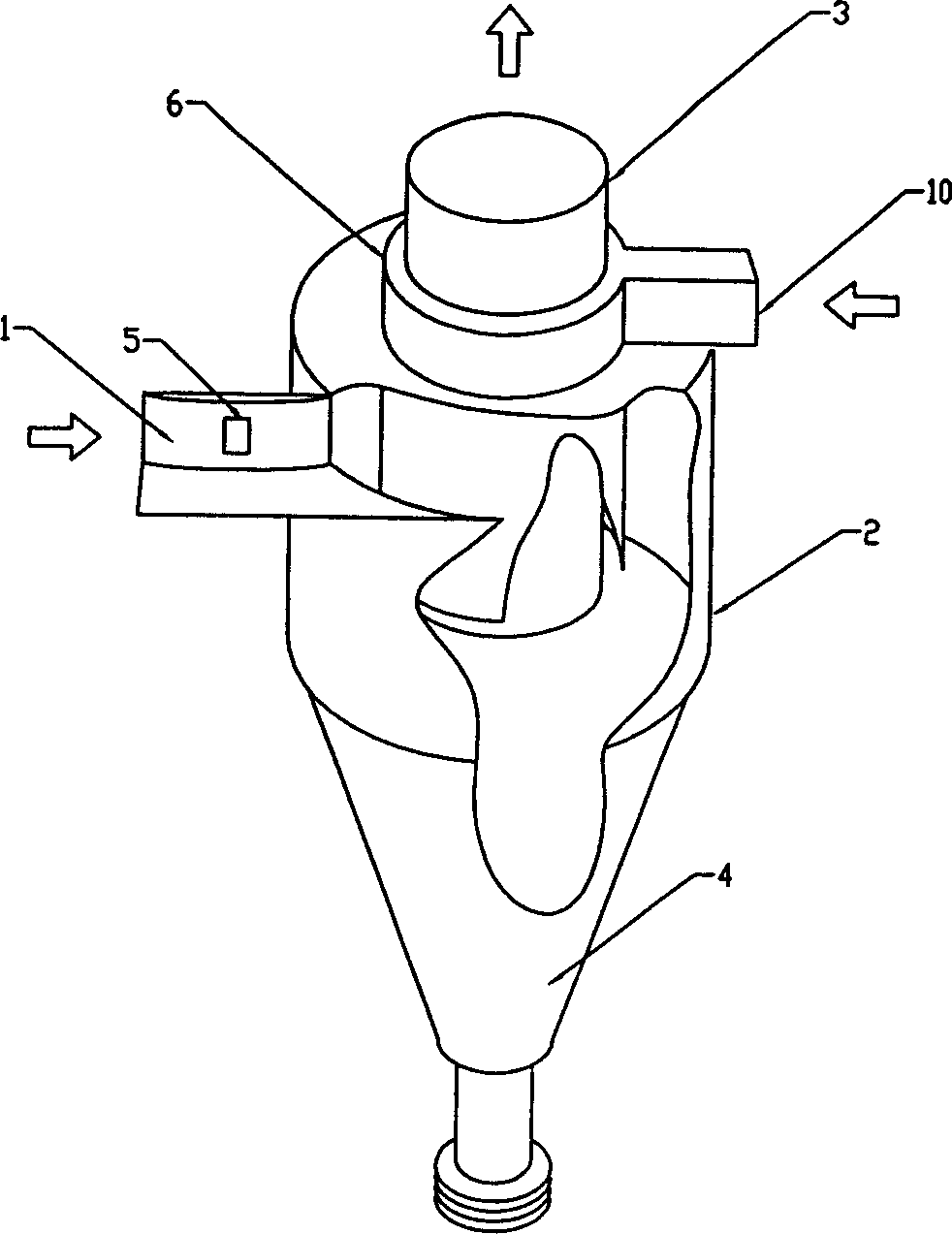

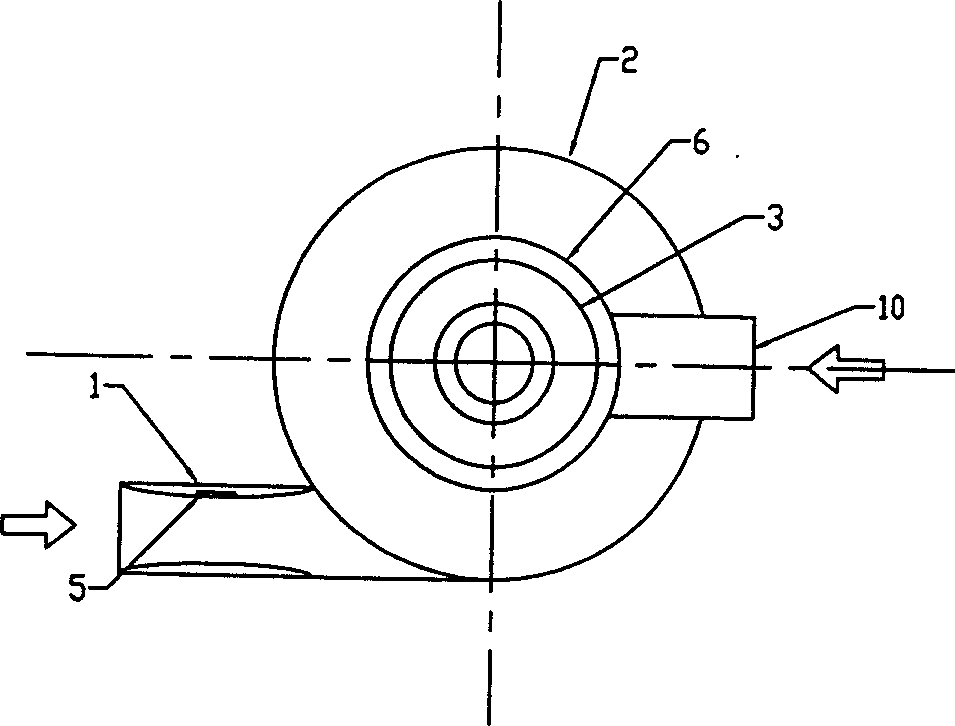

[0013] A fluidized bed boiler with a multifunctional cyclone separator provided by the present invention comprises a fluidized bed boiler combustion chamber and a cyclone separator arranged outside the outlet of the fluidized bed boiler combustion chamber, and the fluidized bed boiler combustion chamber includes a bottom of the combustion chamber The air distribution plate 7, the high-speed fluidization zone 8 above the air distribution plate and the gas phase combustion zone 9 on the upper part of the combustion chamber; the cyclone separator includes an inlet section 1, an outer cyclone tube 2 communicated with the inlet section, and is arranged on the outer cyclone Exhaust cylinder 3 and conical ash bin 4 in the cylinder. The shape of the inner wall of the inlet section 1 is a Venturi constriction, and a gas burnout tuyere 5 is installed on the inlet section. On the one hand, the mouth-shaped inlet section makes it easier for the gas overburning air to blow through the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com