Automobile semiaxle wedge cross-rolling precision shaping method

A technology for precision forming and automobile half shafts, applied in the direction of metal rolling, etc., can solve the problems of production efficiency of expensive forging methods, huge manufacturing cost of equipment, large diameter of half shaft molds, etc. The effect of reducing the number of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

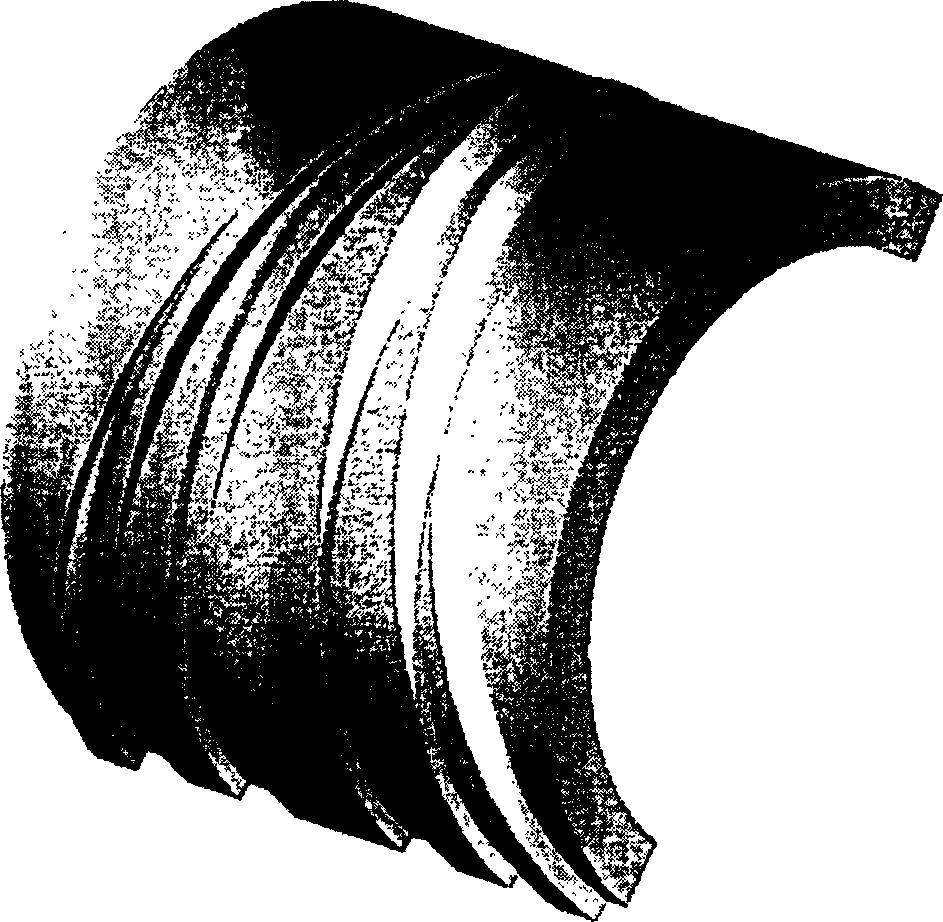

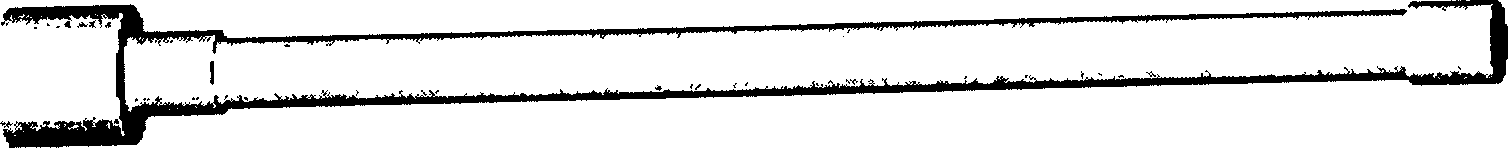

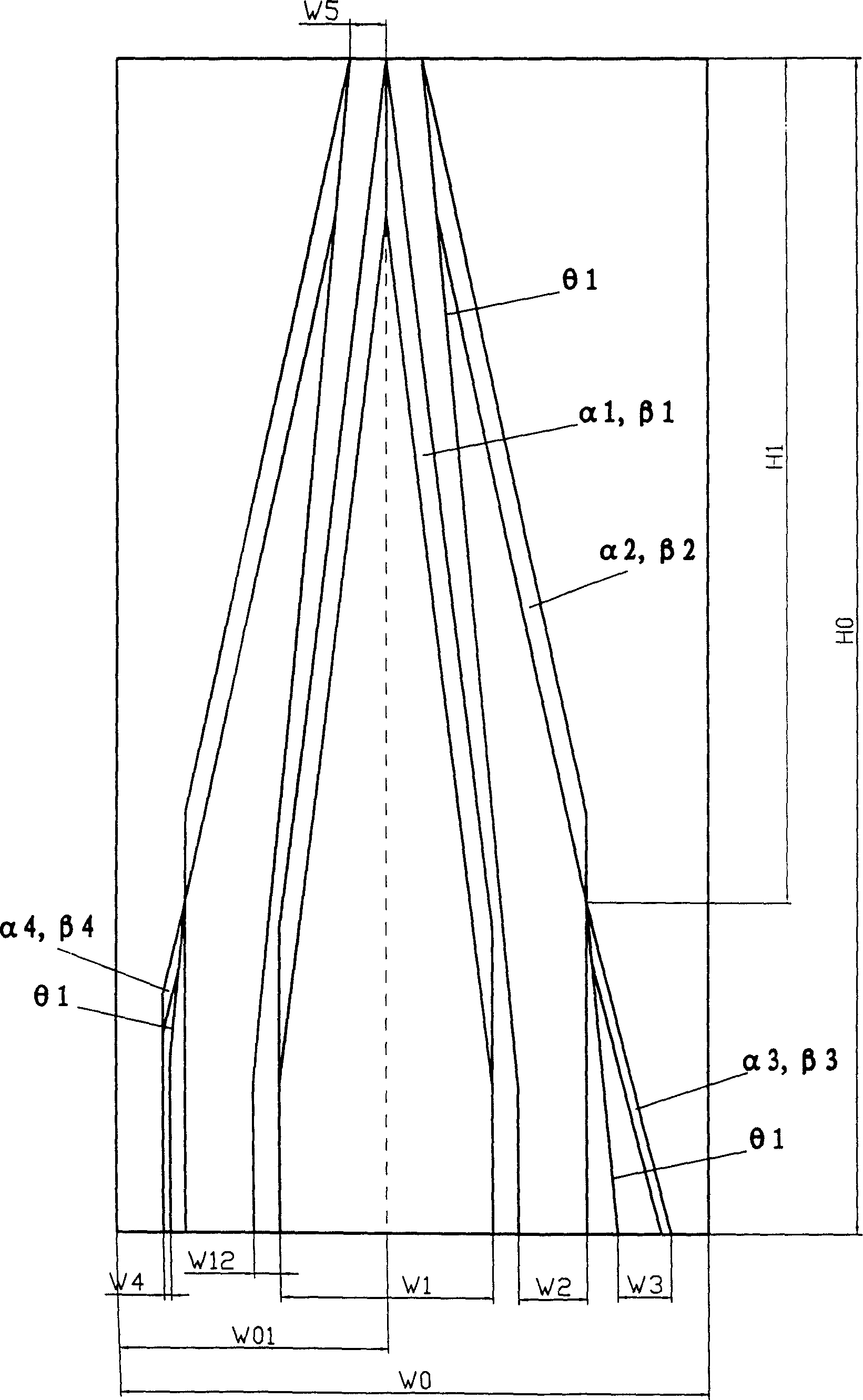

[0021] image 3 , Figure 4 and Figure 5 It is an embodiment of the multi-wedge precision forming of the semi-axle of the rear axle of the automobile. 3. Rolling is carried out between the half-axle molds of the rear axle of the wedge car. The maximum diameter of the mold is Φ850mm. The expansion diagram of the mold is as follows: image 3 , the semi-axle rolling products of automobile rear axle such as Figure 4 shown, will Figure 4 Flat forging or oscillating rolling is performed on the unrolled end of the finished automobile rear axle half-axle, and then local finishing is performed to obtain the finished automobile rear axle half-axle such as: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com