Automobile semiaxle wedge cross-rolling precision shaping method

A technology of precision forming and automobile half shaft, which is applied in the direction of metal rolling, can solve the problems of expensive forging method production efficiency, huge manufacturing cost of equipment, large diameter of half shaft mold, etc., and achieve low production cost, reduced production cost, machine The effect of reducing processing steps

Inactive Publication Date: 2004-09-15

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a multi-wedge precision forming method for automobile half-shaft cross-wedge rolling, which solves the problems of single-wedge production half-shaft die diameter, huge equipment, expensive manufacturing cost, low production efficiency and low material utilization rate of the forging method. , realize the economical production of half shaft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

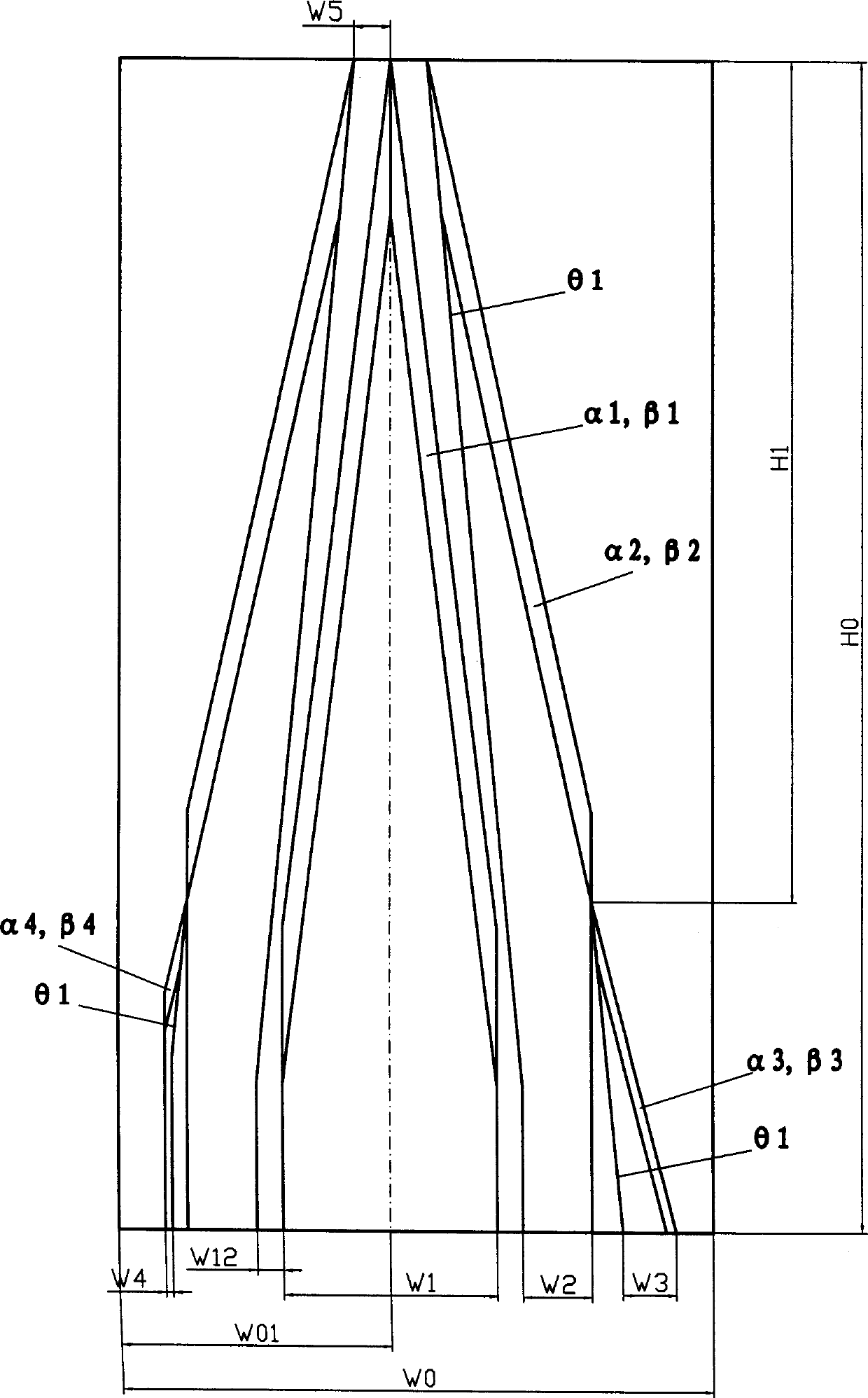

The invention provides a wedge cross-rolling multi-wedge precisely-molding method of auto half shaft, installing multi-wedge mould with 2-6 wedge pairs in the wedge cross roller to roll the half shaft, heating circular stick to 1000-2000 deg.C, inputting two parallel-rotating multi-wedge moulds with 2-6 wedge pairs through axial feeding device to roll. The mould parameters: molding angle, alpha=18-34 degrees, stretching angle, beta=4-12 degrees. It can roll the half shaft at the same time.

Description

technical field The invention belongs to the technical field of plastic forming of shaft parts, and in particular provides a multi-wedge precision forming method for automobile half shaft cross wedge rolling, which is suitable for rolling forming of large long shaft parts. Background technique The car half shaft is one of the key parts of the car, which belongs to the large long shaft part (greater than 900mm). At present, there are two main methods of producing half shafts at home and abroad: 1) Forging and forming, its production efficiency is 0.3-0.5 pieces per minute, and the material utilization rate is about 65%; 2) cross wedge rolling and single wedge rolling, its production efficiency is 2-6 pieces per minute, and the material utilization rate is 78-82%. Cross wedge rolling, single wedge rolling forming and forging forming, although the production efficiency and material utilization rate have been greatly improved, but because the half shaft is a large long sha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21H1/00

Inventor 束学道胡正寰邢希东王宝雨张康生李玉京张巍刘晋平杨翠平

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com