Wedge cross-rolling two cycle roll forming method for automobile half-shaft blank

A technology of semi-shaft and cross-wedge rolling for automobiles, which is applied in the direction of metal rolling, metal rolling, rolls, etc., which can solve the problems of high mold cost and large equipment investment, and achieve equipment weight reduction, simple mold structure, and high rolling force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

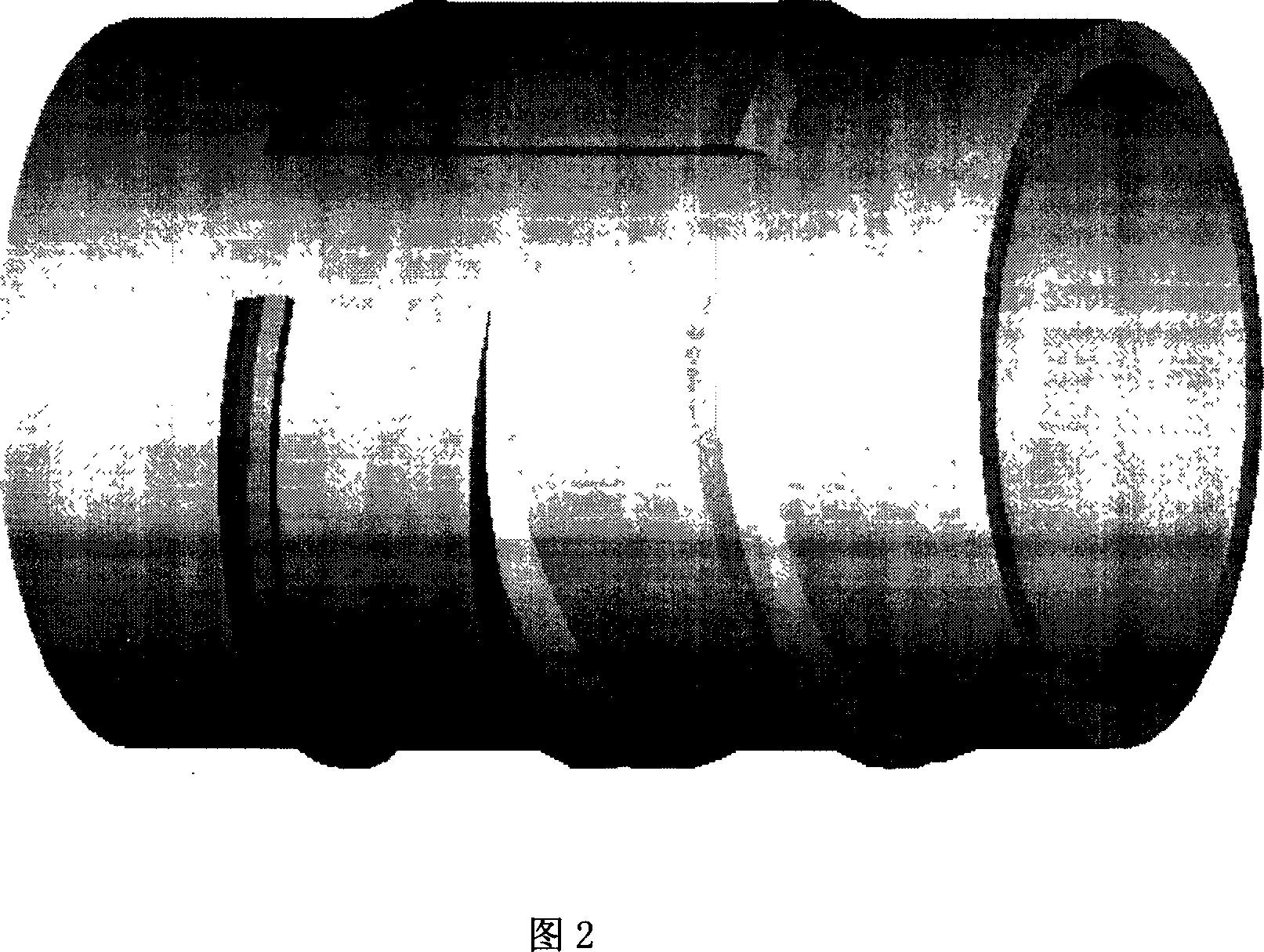

[0030] Fig. 2 and Fig. 7 are die diagrams of an implementation example of forming an automobile semi-shaft blank by cross-wedge rolling with two turns. Figure 3 shows the blank Φ100×468.5mm. The billet is heated to 950°C to 1200°C, and is fed between two co-rotating molds through an axial feeding device for rolling. The diameter of the top circle of the mold is φ1000mm. Figure 4 and Figure 5 are respectively the parts diagrams formed after the first and second rounds of rolling are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com