Automatic disassembling scrubbing apparatus for treating discharge gas

A technology of exhaust gas and automatic disassembly, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, combustion methods, etc., can solve inconvenience and other problems, achieve the effects of extended service life, convenient maintenance and management, and simple cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

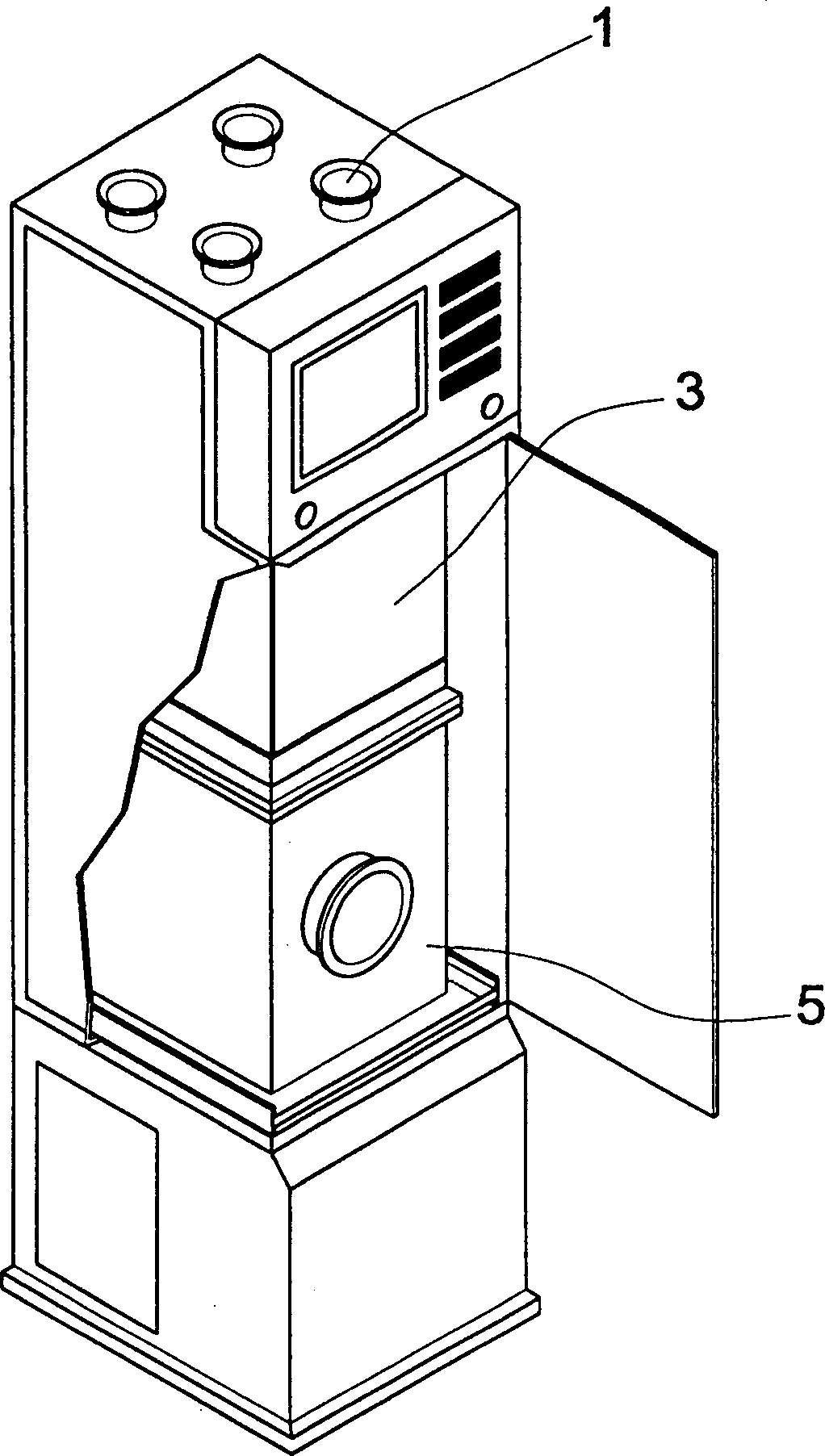

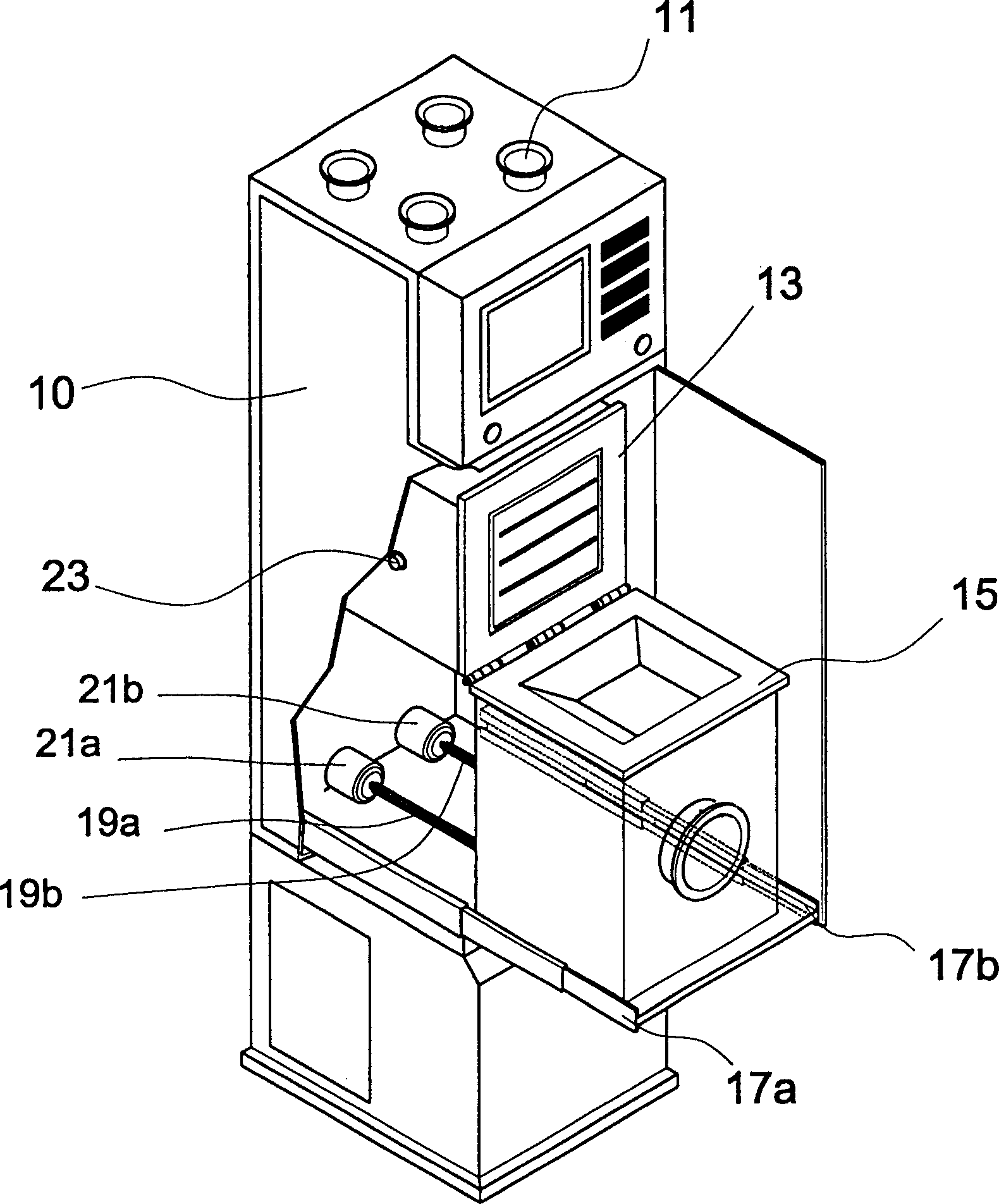

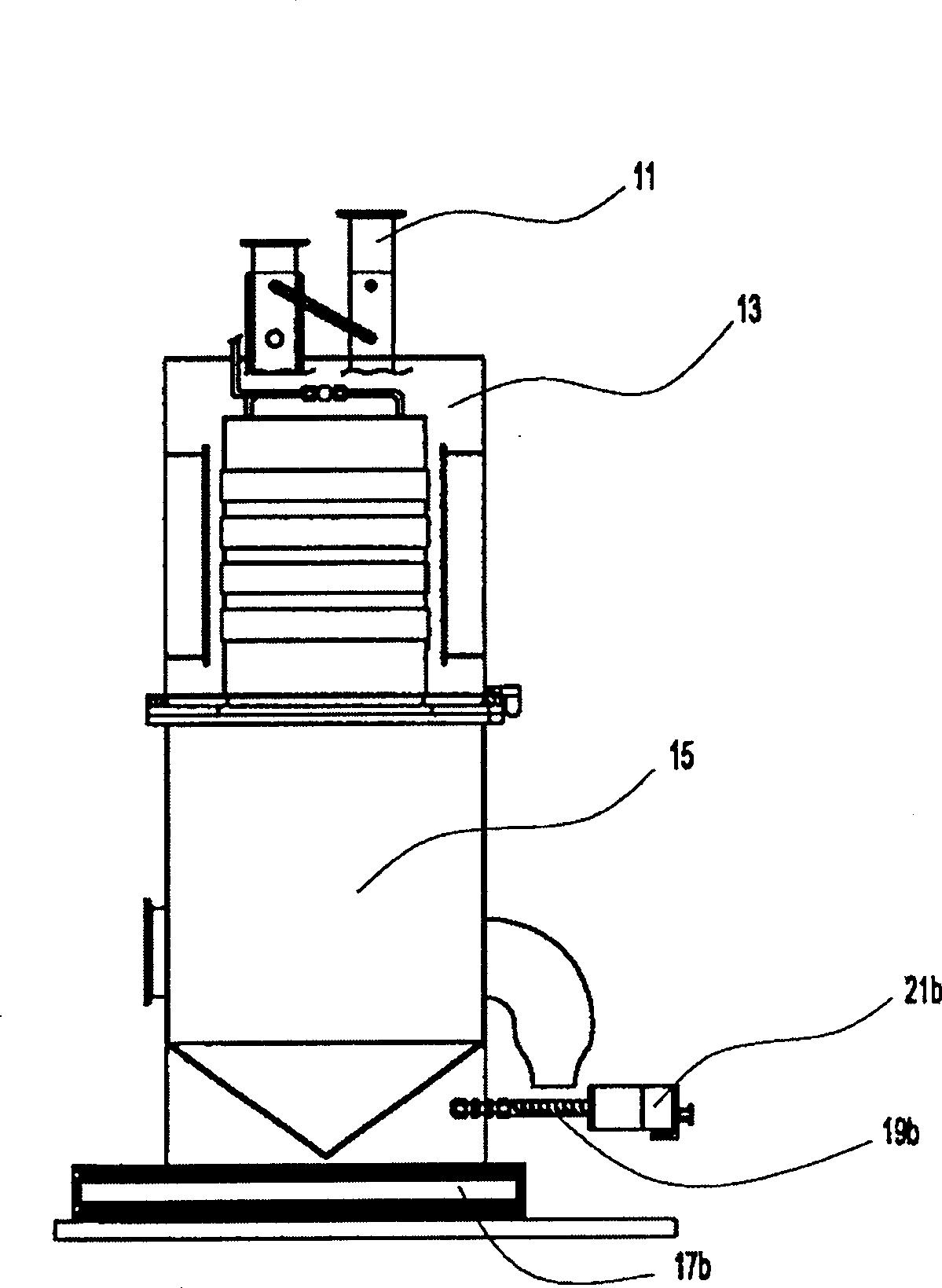

[0013] exist figure 2 Among them, the gas scrubber of the present invention is also made up of inlet 11, combustion chamber 13, wet processing chamber 15, discharge port (not shown in the figure) and the casing that accommodates combustion chamber 13 and wet processing chamber 15, etc. Wherein, the discharged gas will flow into the inflow port 11; the combustion chamber 13 is connected to one end of the inflow port 11, and the exhaust gas flowing in is combusted; the wet process chamber 15 is connected to the lower end of the combustion chamber 13, and it will clean Water-soluble harmful substances in the exhaust gas that has been combusted through the combustion chamber 13; the discharge port is connected to one end of the wet processing chamber 15, and it will discharge the treated exhaust gas to the outside.

[0014] This scrubbing device is specially provided with horizontally moving guide mechanisms 17a and 17b at the lower ends of both sides of the wet processing chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com