Mechanical system apparatus for axle bush thickness automatic checking-sorting machine

An automatic detection and mechanical system technology, applied in measuring devices, mechanical equipment, and optical devices, etc., can solve the problems of low measurement accuracy, difficult automatic grading and grading of bearing bushes, and inability to meet the requirements of medium and high-end markets. The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

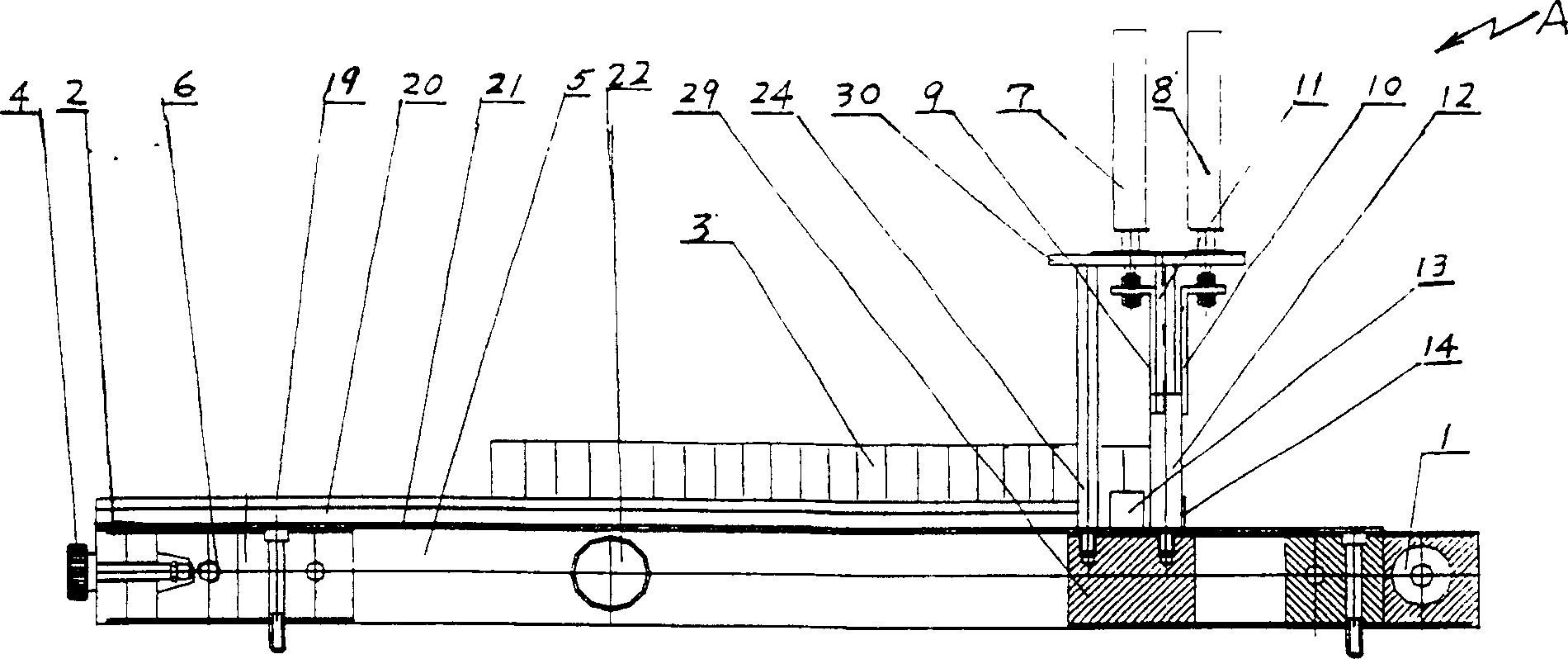

[0013] Referring to the above-mentioned drawings, the implementation of the technical solution of the present invention will be described in detail.

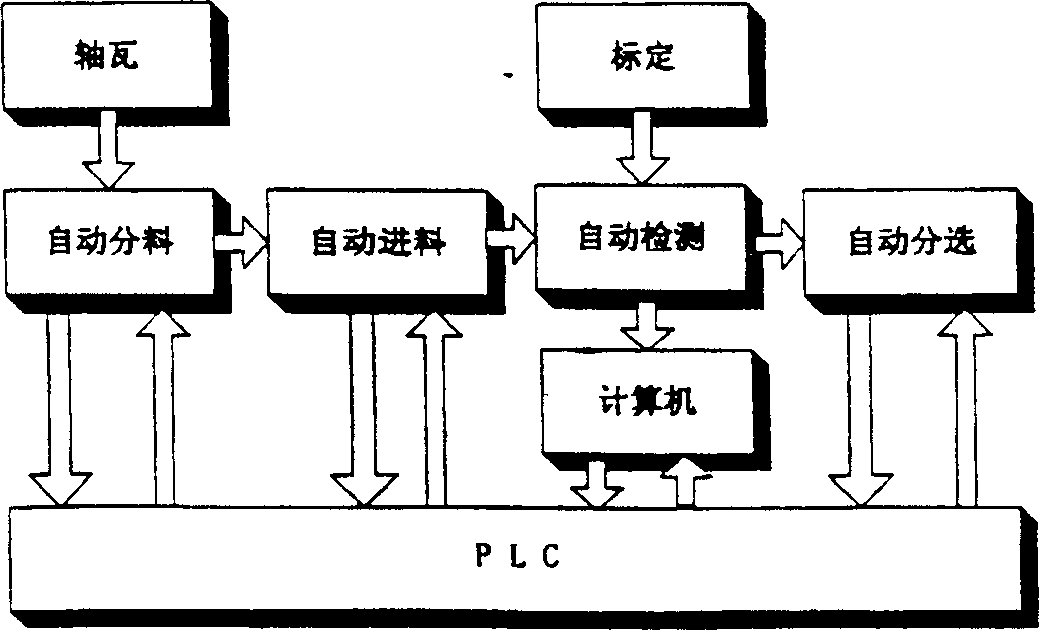

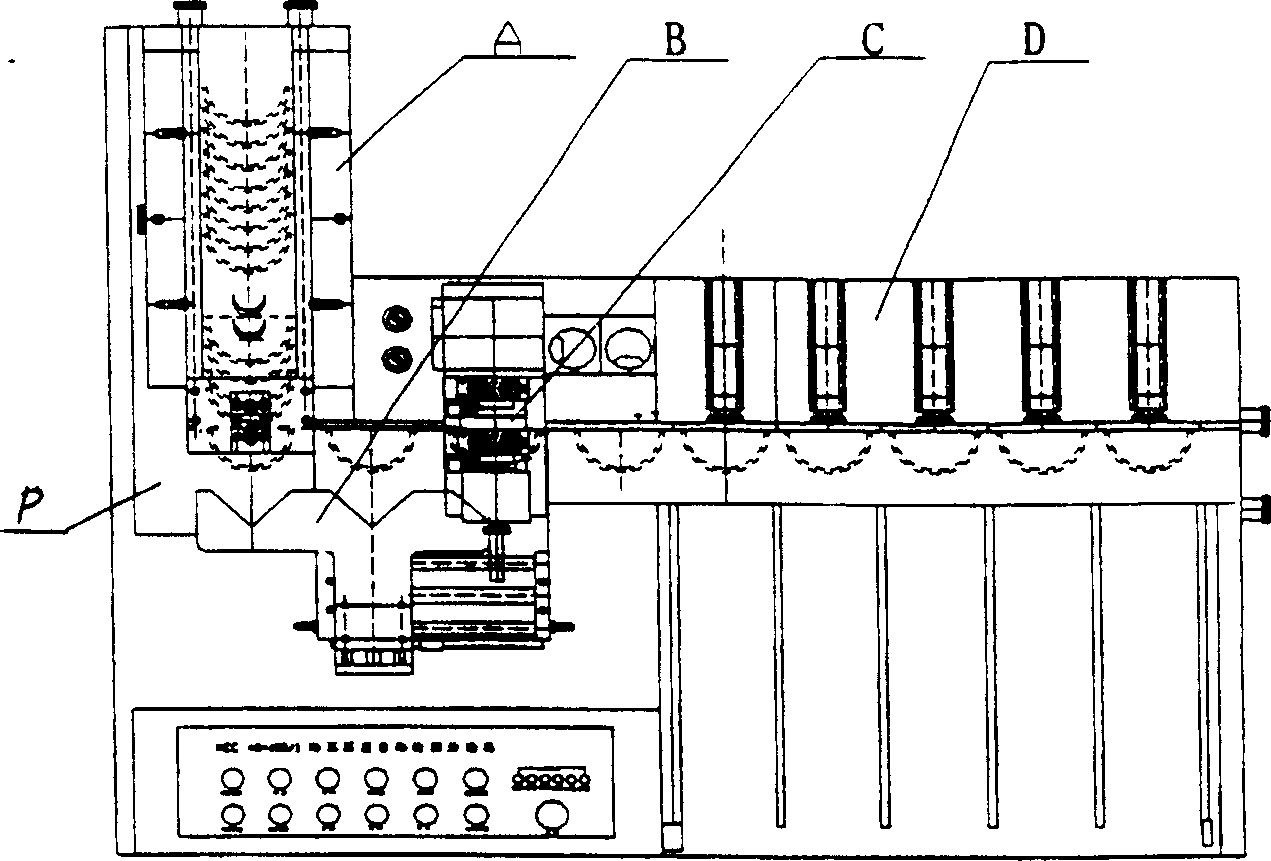

[0014] The present invention creates the overall working principle of the automatic detection and sorting machine for bearing pad thickness, such as figure 1 shown. The bearing pads are controlled by the PLC control system to automatically divide, feed, detect and sort in sequence according to a certain rhythm. The computer collects and processes the data of the thickness detection results of the bearing pads. Through the PLC control system, the thickness of the bearing pads is automatically determined according to the detection results. Sorting, storage, supply and shaft group interchange assembly. The PLC automatic control system includes 13 cylinders, including 5 sorting cylinders, 2 material distribution cylinders, 2 measuring vertical up and down movement cylinders, 1 measuring cylinder, 1 grating gauge cylinder, and 2 shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com