Method of preparing platinum ruthenium/carbon two-element compounded catalyst of positive electrode of alcohol fuel cell

A methanol fuel cell, binary compound technology, applied in physical/chemical process catalysts, battery electrodes, metal/metal oxide/metal hydroxide catalysts, etc., can solve unfavorable mass production, difficulty in controlling the dispersion of metal particles, Problems such as fast reaction speed of impregnation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 6.2 mmol SnCl 2 2H 2 O placed in 70 ml of 1.25 mol / L NaOH solution at 20°C for 10 minutes of ultrasonic vibration, after it is completely dissolved, add 20.61 grams of carbon black XC-7, and then ultrasonic vibration for 20 minutes to disperse the carbon black, and then at high speed While stirring, add 25 mL of RuCl all at once 3 and H 2 PtCl 6 A mixed solution containing RuCl 3 and H 2 PtCl 6 Both were 0.51 mmol, and stirred at high speed for 8 hours at 20°C. Pour off the liquid after standing to separate, then filter. Then first wash the filter residue with 1.25 mol / L NaOH, and then wash it repeatedly with hot deionized water. After filtering and washing, the filter residue was dried in an oven at 80° C. for 24 hours.

[0019] The product of this embodiment is marked as A, and thermogravimetric analysis shows that the yield of Pt and Ru is above 98%.

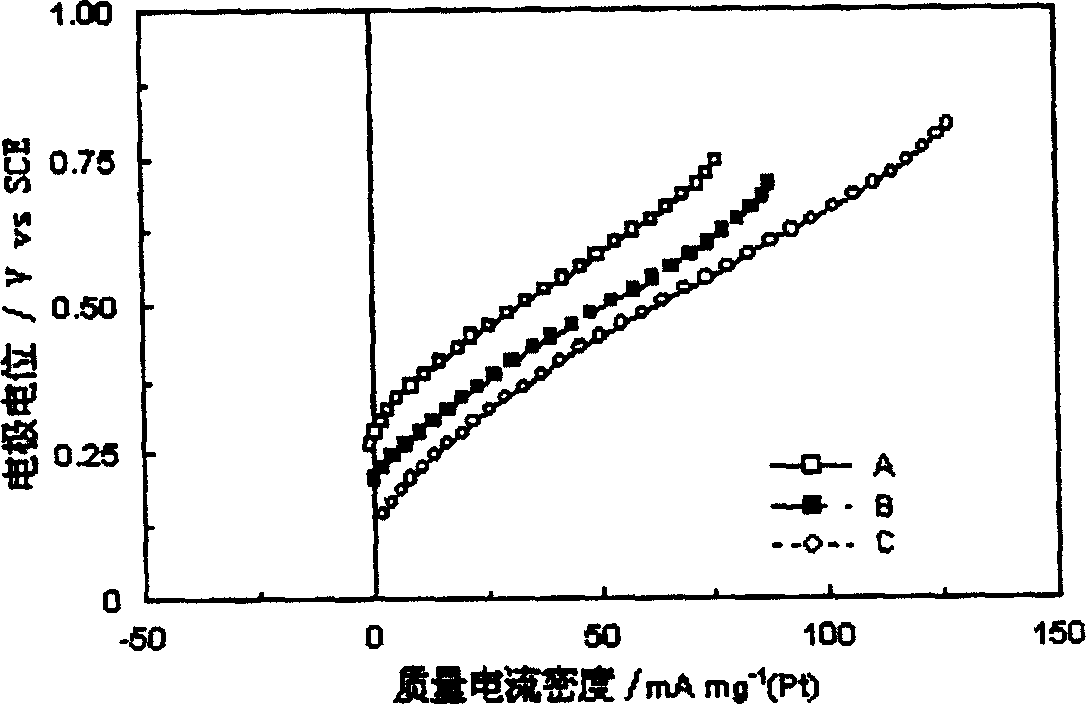

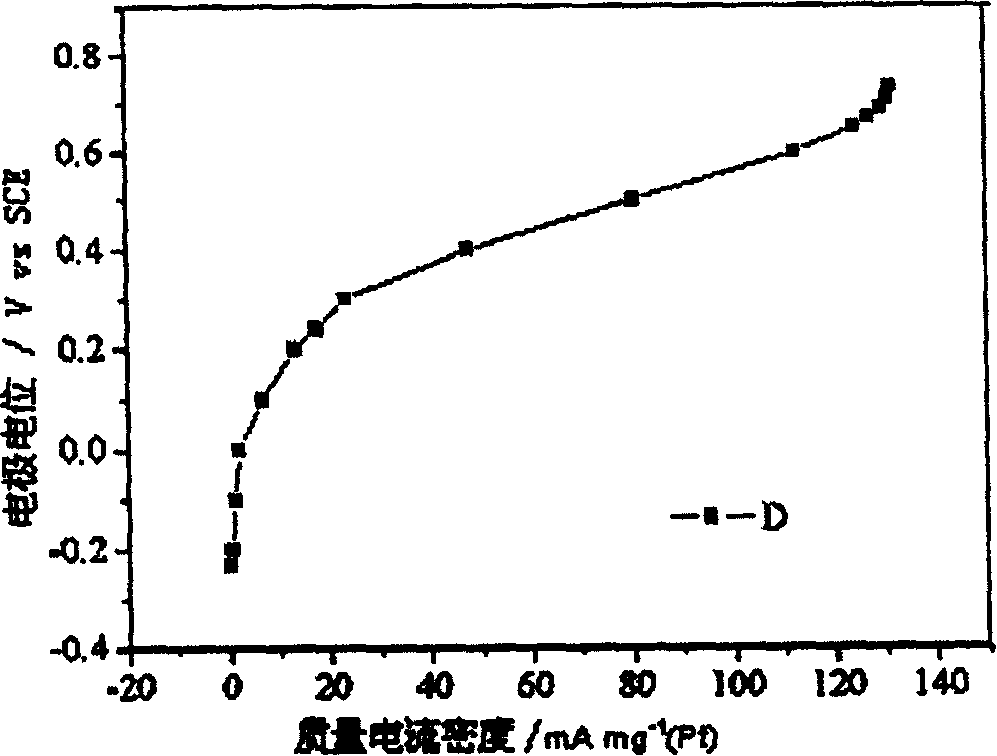

[0020] Product A at 1 mol / L H 2 SO 4 +1 mol / L CH 3 The steady-state polarization curve of OH, such...

Embodiment 2

[0022] Take 6.2 mmol SnCl 2 2H 2 O placed in 70 ml of 1.25 mol / L NaOH solution at 20°C for 10 minutes of ultrasonic vibration, after it is completely dissolved, add 20.61 grams of carbon black XC-7, and then ultrasonic vibration for 20 minutes to disperse the carbon black, and then in 50 °C, while stirring at high speed, add 60 ml of RuCl dropwise 3 and H 2 PtCl 6 A mixed solution containing RuCl 3 and H 2 PtCl 6 Both are 0.51 mmol, and the dropwise addition time is 4 hours, and after the dropwise addition is completed, the insulation and stirring are continued for 1 hour. Pour off the liquid after standing to separate, then filter. Then first wash the filter residue with 1.25 mol / L NaOH solution, and then wash it repeatedly with hot deionized water. After filtering and washing, the filter residue was dried in an oven at 80° C. for 24 hours.

[0023] The product of this embodiment is marked as B, and thermogravimetric analysis shows that the yield of Pt and Ru is abov...

Embodiment 3

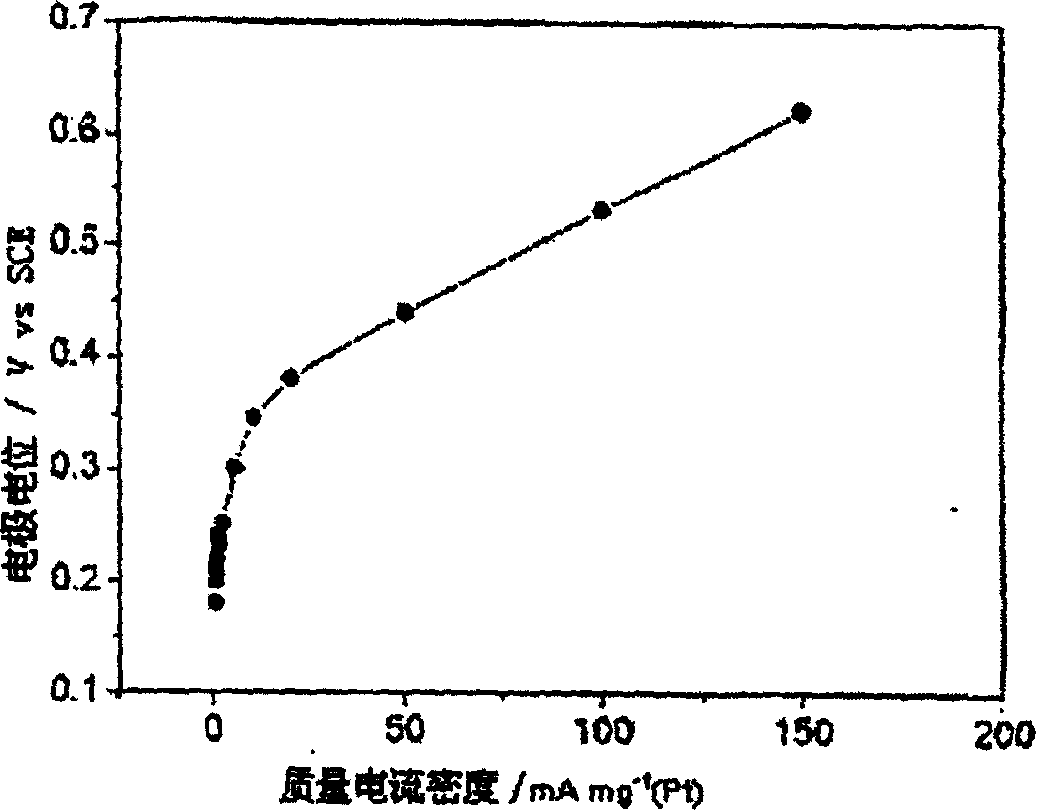

[0026] Take 12.3 mmol SnCl 2 2H 2 O placed in 106 ml of 1.25 mol / L NaOH solution at 20°C for 10 minutes of ultrasonic vibration, after it is completely dissolved, add 1.21 g of carbon black XC-7, and then ultrasonic vibration for 20 minutes to disperse the carbon black and dilute to 280 ml, heated to 80°C, then added dropwise 100 ml of RuCl while stirring at high speed 3 and H 2 PtCl 6 A mixed solution containing RuCl 3 and H 2 PtCl6 Both are 1.025 mmoles, and the dropwise addition time is 2 hours, and after the dropwise addition is completed, the insulation and stirring are continued for 1 hour. Pour off the liquid after standing to separate, then filter. Then first wash the filter residue with 1.25 mol / L NaOH, and then wash it repeatedly with hot deionized water. After filtering and washing, the filter residue was dried in an oven at 80° C. for 24 hours. After drying, a part was directly used for performance testing, and this part of the product was marked as C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com